3628606

Pipe Plug

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3628606 Pipe Plug is a component designed for use in commercial truck systems. Its primary role is to seal openings in fluid systems, ensuring the integrity and efficiency of the system. This part is integral to maintaining the operational standards of commercial trucks, particularly in environments where fluid systems are subject to various stresses and conditions 1.

Basic Concepts of Pipe Plugs

Pipe plugs are components used in fluid systems to seal openings, preventing the escape of fluids and the ingress of contaminants. They operate by fitting into a threaded or non-threaded opening and creating a secure seal. The effectiveness of a pipe plug is determined by its material, design, and the precision of its fit within the system 2.

Purpose of the Cummins 3628606 Pipe Plug

The Cummins 3628606 Pipe Plug serves a specific function in the operation of a truck by sealing openings in fluid systems. This sealing action is vital for maintaining system pressure, preventing fluid leaks, and protecting the system from external contaminants. Its role is particularly important in systems where fluid integrity is crucial for performance and safety 3.

Key Features

The Cummins 3628606 Pipe Plug is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the pressures and temperatures of commercial truck fluid systems, and its design specifications, which ensure a secure and reliable fit. Unique attributes may include corrosion resistance and ease of installation, contributing to its effectiveness in demanding environments.

Benefits

Utilizing the Cummins 3628606 Pipe Plug offers several advantages. It contributes to improved system integrity by effectively sealing openings, thus preventing fluid leaks. This not only enhances the efficiency of the system but also reduces the risk of damage caused by fluid loss or contamination. Additionally, its robust design and material properties ensure long-term reliability and performance.

Installation Process

Proper installation of the Cummins 3628606 Pipe Plug involves several steps to ensure a secure fit. Initially, the opening must be cleaned and inspected for any damage. The pipe plug is then inserted into the opening, ensuring it is aligned correctly. Tools may be required to tighten the plug to the appropriate specification, ensuring a seal that is both secure and durable.

Troubleshooting Common Issues

Common issues associated with pipe plugs include leaks and corrosion. Diagnosing these problems involves inspecting the plug and the surrounding area for signs of damage or wear. Resolving these issues may require cleaning the area, replacing the plug if it is damaged, or addressing any underlying system problems that may be contributing to the issue.

Maintenance Tips

Regular maintenance of the Cummins 3628606 Pipe Plug is important for ensuring its longevity and reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the plug and surrounding area to prevent buildup, and ensuring that the seal remains intact. Following manufacturer guidelines for inspection intervals and maintenance procedures will help maintain the integrity of the fluid system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications. Cummins is renowned for its commitment to quality, performance, and customer satisfaction in the commercial truck industry.

Cummins Pipe Plug 3628606 Compatibility with Various Engine Models

The Cummins Pipe Plug part number 3628606 is designed to fit a range of engine models, ensuring compatibility with various configurations. Below is a detailed overview of the engines with which this part is compatible:

G855 Series Engines

- G855 CM558

- GTA855 CM558 (CM2358) G101

K Series Engines

- K19

- K38

- K50

KTA38 Series Engines

- KTA38 GC CM558

N14 Series Engines

- N14 G

- N14 MECHANICAL

QSK Series Engines

- QSK19 CM2350 K105

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK78 CM500

- QSK95 CM2350 K113

QSN14 Series Engines

- QSN14 CM876 N103

V Series Engines

- V28

The Pipe Plug 3628606 is engineered to ensure a secure fit across these diverse engine models, providing a reliable sealing solution for various applications.

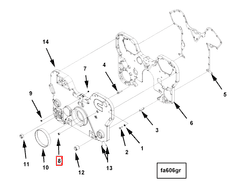

Role of Part 3628606 Pipe Plug in Engine Systems

The part 3628606 Pipe Plug is an essential component in various engine systems, ensuring the integrity and functionality of several critical areas.

Base Mounting and Pan Components

In the base mounting pan and base pan, the Pipe Plug is utilized to seal openings, preventing fluid leaks and maintaining the structural integrity of the base part. It also plays a role in the base rails by securing fluid pathways and ensuring that no contaminants enter the system.

Engine Block and Cylinder

Within the block and cylinder, the Pipe Plug is employed to seal off coolant or oil passages that are not in use. This helps in maintaining the correct fluid levels and pressures within the engine, contributing to efficient operation and longevity of the components.

Camshaft and Gear Assembly

In the camshaft and gear system, the Pipe Plug is used to seal off lubrication passages. This ensures that the camshaft and associated gears receive a consistent supply of lubricant, reducing wear and tear and enhancing the reliability of the engine’s timing mechanism.

Compressor and Air System

For the compressor and air system, the Pipe Plug is crucial in sealing refrigerant lines. This prevents leaks that could compromise the efficiency of the air conditioning system and ensure that the compressor operates within optimal parameters.

Water Inlet and Outlet Connections

At the water inlet and water outlet connections, the Pipe Plug is used to cap off unused coolant passages. This maintains the efficiency of the cooling system by ensuring that coolant flows only through the necessary pathways, thus optimizing engine temperature regulation.

Hand Hole and Engine Mounting

In the cover hand hole and engine mounting areas, the Pipe Plug seals small openings, preventing debris from entering sensitive areas and ensuring that mounting points remain secure and free from contamination.

Exhaust Manifold and Injectors

The Pipe Plug is also found in the exhaust manifold and near injectors, where it seals off coolant passages that are not in use. This helps in maintaining the precise temperature control around the injectors, which is vital for fuel delivery and combustion efficiency.

Keel Cooling and Auxiliary Systems

In the keel cooling system and auxiliary cooling setups, the Pipe Plug ensures that coolant pathways are correctly sealed, preventing leaks and maintaining the effectiveness of these cooling systems.

Thermostat Housing and Oil Systems

Finally, in the thermostat housing and various oil systems such as the oil drain valve, oil top level assembly pan, and oil transfer connection, the Pipe Plug plays a role in sealing off passages to maintain fluid levels and pressures, ensuring the engine operates smoothly and efficiently.

Conclusion

The Cummins 3628606 Pipe Plug is a critical component in maintaining the integrity and efficiency of commercial truck fluid systems. Its robust design, material properties, and precise fit ensure reliable performance across a variety of engine models. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall performance and longevity of the engine systems in which it is used.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.