This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

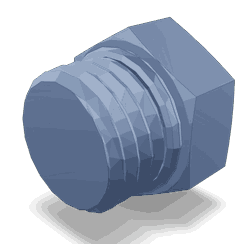

The Cummins 3628610 Pipe Plug is a critical component for commercial trucks, designed to seal openings in fluid systems. This ensures the integrity and efficiency of these systems by preventing fluid leaks and contamination, thereby maintaining the operational standards of trucks 1.

Basic Concepts of Pipe Plugs

A pipe plug is a device used to seal the end of a pipe or fitting in a fluid system. Its primary function is to prevent fluid escape and keep contaminants out, which is vital for maintaining system pressure and fluid purity 2.

Purpose of the Cummins 3628610 Pipe Plug

The Cummins 3628610 Pipe Plug is designed to seal openings in fluid systems, ensuring that fluids remain contained. This prevents leaks that could lead to system failure or contamination, contributing to the truck’s reliability and performance 3.

Key Features

This Cummins part is characterized by its robust design and material composition. It is typically made from high-quality materials that resist corrosion and wear, ensuring durability in demanding environments. Its design allows for a secure fit, crucial for effective sealing, and may feature threads or other mechanisms for easy installation and removal 4.

Benefits of Using the Cummins 3628610 Pipe Plug

Utilizing this part offers several advantages. It enhances system reliability by providing a secure seal that prevents fluid leaks. The ease of installation reduces downtime during maintenance procedures. Furthermore, its durability leads to long-term cost savings, as it requires less frequent replacement compared to lower-quality alternatives 1.

Installation Process

Installing the Cummins 3628610 Pipe Plug involves cleaning the fitting, screwing the plug into place, and tightening it to the manufacturer’s specified torque to achieve a proper seal. Tools such as a torque wrench may be required to ensure the correct tightness is achieved 2.

Troubleshooting Common Issues

Common problems with pipe plugs include leaks and corrosion. If a leak is detected, the pipe plug should be inspected for proper seating and tightness. Corrosion can be addressed by cleaning the affected area and applying a compatible sealant or replacing the pipe plug if necessary. Regular inspections can help identify issues before they lead to significant problems 3.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3628610 Pipe Plug, regular maintenance is recommended. This includes periodic inspections for signs of wear or corrosion, and cleaning the plug and its fitting to remove any buildup. Following the manufacturer’s guidelines for maintenance intervals and procedures will help maintain the integrity of the fluid system 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and approximately 7,400 dealer locations.

Compatibility with Cummins Engines

The Cummins part 3628610, a Pipe Plug, is designed to fit seamlessly with a range of Cummins engines, ensuring a secure and reliable seal. This part is compatible with the following engines:

- K19

- K38

- K50

- KTA38GC CM558

Additionally, the Pipe Plug is also suitable for the following engines:

- QSK38 CM2150 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

This part is engineered to provide a precise fit, ensuring optimal performance and longevity across these engine models. It is crucial for maintaining the integrity of the engine’s piping system, preventing leaks and ensuring efficient operation.

Role of Part 3628610 Pipe Plug in Engine Systems

Part 3628610 Pipe Plug is an essential component in various engine systems, ensuring the integrity and efficiency of fluid pathways. It is strategically placed in several key areas to prevent leaks and maintain system pressure.

Fuel System Integration

In the fuel system, the Pipe Plug is utilized in the Fuel Left Bank Manifold, Fuel Left Hand Manifold, and Fuel Right Bank Manifold. Its role here is to seal off unused ports or passages, ensuring that fuel flows only through the intended pathways. This helps in maintaining consistent fuel pressure and preventing any potential fuel leaks that could compromise engine performance or safety.

Lubricating Oil System

Within the Lubricating Oil system, the Pipe Plug is employed in the Lubricating Oil Filter and Lubricating Oil Filter Head. By sealing off unnecessary openings, it ensures that the oil circulates efficiently through the filter, enhancing the filtration process and prolonging the life of the engine’s moving parts.

Hydraulic and Water Pump Systems

In the Front Hydraulic Pump and Hydraulic Pump Support, the Pipe Plug plays a significant role in maintaining system pressure and preventing fluid loss. Similarly, in the Water Pump Support and Water Pump Top Level Assembly Shaft, it ensures that coolant flows smoothly without any interruptions, which is vital for maintaining optimal engine temperature.

Accessory and Drive Systems

The Pipe Plug is also found in various Drive and Accessory systems, such as the Front Gear Train Accessory and EBM-Drive. Here, it helps in sealing off sections that are not in use, thereby ensuring that the drive systems operate without any fluid contamination or loss.

Fuel Transfer and Mounting Systems

In the Fuel Transfer Kit and Fuel Transfer Pump Mounting, the Pipe Plug ensures that the fuel transfer process is leak-free and efficient. It also plays a role in the Engine Mounting and Mounting Fuel System Accessory by sealing off any unnecessary passages, thereby contributing to the overall structural integrity of the engine system.

Plumbing and Injector Systems

Lastly, in the Plumbing and Injector systems, the Pipe Plug is used to seal off sections that are not in use, ensuring that the fluid dynamics within these systems remain optimal. This is particularly important in high-pressure systems where even a small leak can lead to significant performance issues.

Overall, Part 3628610 Pipe Plug is a versatile component that enhances the reliability and efficiency of various engine systems by ensuring fluid pathways are sealed and pressure is maintained.

Conclusion

The Cummins 3628610 Pipe Plug is a vital component in maintaining the integrity and efficiency of fluid systems in commercial trucks. Its robust design, ease of installation, and durability make it a reliable choice for preventing fluid leaks and contamination. Regular maintenance and proper installation are key to ensuring its optimal performance and longevity.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ ↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ ↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ ↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.