This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

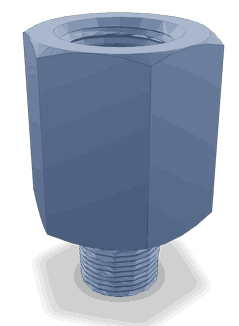

The 3819618 Reducing Pipe Coupler is a component manufactured by Cummins, a well-established name in the commercial truck industry. This coupler is designed for use in fluid systems within commercial trucks, where it facilitates the connection of pipes with different diameters. Pipe couplers, in general, play a role in fluid systems by ensuring the smooth and efficient transfer of fluids between components of varying sizes 1.

Basic Concepts of Reducing Pipe Couplers

A reducing pipe coupler is a fitting used to join two pipes of different diameters within a fluid system. It operates on the principles of fluid dynamics, allowing for the transition of fluid flow from a larger pipe to a smaller one, or vice versa, without significant loss of pressure or efficiency. The design of these couplers ensures that the fluid maintains a consistent flow rate and pressure, which is important for the proper functioning of the system 2.

Purpose of the 3819618 Reducing Pipe Coupler

The 3819618 Reducing Pipe Coupler is specifically designed to connect pipes of different diameters in the fluid systems of trucks. Its role is to facilitate the efficient flow of fluids between these pipes, ensuring that the system operates smoothly. By accommodating the difference in pipe sizes, this coupler helps maintain the integrity of the fluid system, allowing for optimal performance of the truck’s various fluid-dependent components.

Key Features

The 3819618 Reducing Pipe Coupler boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design specifications of this coupler are tailored to fit snugly with pipes of different diameters, promoting a secure connection. Additionally, it may include unique attributes such as reinforced seals or specialized coatings that further improve its functionality and longevity.

Benefits

Utilizing the 3819618 Reducing Pipe Coupler offers several advantages. Its design contributes to improved efficiency in fluid transfer, reducing the risk of leaks and ensuring a consistent flow rate. The durability of the materials used in its construction means it can withstand the rigors of commercial truck operations, offering a long service life. Furthermore, its ease of installation compared to alternative solutions makes it a practical choice for maintenance and repair tasks.

Installation Process

Installing the 3819618 Reducing Pipe Coupler requires careful attention to detail. The process involves selecting the appropriate coupler size for the pipes being connected, preparing the pipe ends for a clean and secure fit, and using the necessary tools to ensure a tight connection. Safety precautions, such as wearing protective gear and ensuring the system is depressurized, should be observed throughout the installation process.

Maintenance Tips

To ensure the longevity and optimal performance of the 3819618 Reducing Pipe Coupler, regular maintenance is recommended. This includes routine inspections for signs of wear or damage, cleaning the coupler to remove any buildup that could impede fluid flow, and checking the connections for tightness. Adhering to these maintenance practices helps prevent issues such as leaks or reduced efficiency.

Troubleshooting Common Issues

Common problems with the 3819618 Reducing Pipe Coupler may include leaks or corrosion. Troubleshooting these issues involves identifying the source of the problem, whether it be a loose connection, damaged coupler, or environmental factors contributing to corrosion. Addressing these issues promptly with the appropriate repairs or replacements can help maintain the efficiency and safety of the fluid system.

Compatibility and Applications

The 3819618 Reducing Pipe Coupler is designed for use in various applications within commercial truck systems. Its compatibility with different pipe sizes and materials makes it a versatile component for fluid systems. When integrating this coupler into a system, it is important to consider the specific requirements and conditions of the application to ensure optimal performance and compatibility with other components.

Safety Considerations

When working with the 3819618 Reducing Pipe Coupler, safety protocols should be followed to protect both the technician and the equipment. This includes handling the coupler with care to avoid damage, using appropriate tools and techniques during installation and maintenance, and adhering to operational safety measures to prevent accidents or injuries.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its innovative solutions and commitment to quality. The company’s extensive product range includes a variety of components and systems designed to enhance the performance and efficiency of commercial vehicles.

Reducing Pipe Coupler 3819618 Compatibility with Cummins Engines

The Reducing Pipe Coupler 3819618, manufactured by Cummins, is designed to fit various Cummins engines, ensuring seamless integration and optimal performance. This part is crucial for connecting different sections of the exhaust system, facilitating the transition between varying pipe diameters.

Compatibility with Specific Engine Models

-

6B5.9, 6C8.3, and L10 MECHANICAL Engines The 3819618 Reducing Pipe Coupler is compatible with the 6B5.9, 6C8.3, and L10 MECHANICAL engines. These engines, known for their robust design and reliability, benefit from the precise fit and durability of this coupler, ensuring efficient exhaust flow and reducing back pressure.

-

GTA855 CM558 (CM2358) G101 and QSK50 CM2150 MCRS Engines The coupler also fits the GTA855 CM558 (CM2358) G101 and QSK50 CM2150 MCRS engines. These engines, often used in heavy-duty applications, require components that can withstand high stress and frequent use. The 3819618 part meets these demands, providing a reliable connection that enhances engine performance and longevity.

-

QSK50 CM2350 K108 Engine The QSK50 CM2350 K108 engine is another model that is compatible with the 3819618 Reducing Pipe Coupler. This engine, known for its power and efficiency, relies on precise components to maintain optimal operation. The coupler’s design ensures a secure fit, contributing to the overall efficiency and reliability of the engine.

Ensuring Compatibility and Performance

When integrating the 3819618 Reducing Pipe Coupler into any of these engines, it is essential to verify the specific requirements and dimensions of the engine’s exhaust system. Cummins has engineered this coupler to provide a snug fit, minimizing leaks and ensuring that the exhaust system operates at peak efficiency. Proper installation and maintenance of this component are critical to the engine’s performance and longevity.

Role of Part 3819618 Reducing Pipe Coupler in Engine Systems

The Part 3819618 Reducing Pipe Coupler is integral to the efficient operation of various engine systems. It facilitates the connection between different diameter pipes within the fuel plumbing system, ensuring a seamless transition and maintaining the integrity of fuel flow.

In the fuel plumbing system, this coupler allows for the connection of the fuel lines to the orifice fitting, which is essential for regulating the fuel supply to the engine. This ensures that the fuel is delivered at the correct pressure and volume, which is vital for optimal engine performance.

When integrated with the engine control module (ECM), the Reducing Pipe Coupler helps in maintaining consistent fuel delivery, which is monitored and adjusted by the ECM based on various engine parameters such as load, speed, and temperature.

In the air fuel control system, the coupler plays a role in connecting the fuel lines to the components that manage the air-fuel mixture. This is important for achieving the correct combustion efficiency and reducing emissions.

Additionally, in the engine coolant system, although the Reducing Pipe Coupler is primarily used in fuel lines, its application can extend to coolant systems where different diameter pipes need to be connected. This ensures that the coolant flow is uninterrupted and efficient, contributing to the overall thermal management of the engine.

The coupler also finds its use in the vent system, where it connects different sections of the venting lines, ensuring that fuel vapors are properly managed and directed to the appropriate components for processing or release.

In summary, the Part 3819618 Reducing Pipe Coupler is a versatile component that enhances the functionality and reliability of various engine systems by ensuring smooth and efficient fluid transitions.

Conclusion

The 3819618 Reducing Pipe Coupler is a critical component in the fluid systems of commercial trucks, designed to facilitate the efficient connection of pipes with different diameters. Its high-quality construction, compatibility with various Cummins engines, and role in maintaining the integrity of fluid systems make it an essential part for ensuring optimal engine performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this coupler, contributing to the overall efficiency and safety of the vehicle’s fluid systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.