This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

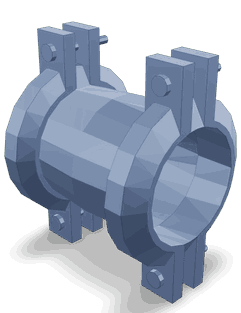

The Cummins 3872294 Pipe Connector is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Pipe Connectors

Pipe connectors are components used in fluid systems to join pipes and other elements, facilitating the transfer of liquids or gases. In automotive applications, these connectors ensure secure and efficient fluid flow, which is vital for the operation of various systems within the vehicle 1. They come in different designs and materials to suit specific applications and environmental conditions.

Purpose of the 3872294 Pipe Connector

The 3872294 Pipe Connector plays a role in the operation of a truck by connecting different parts of the fluid system, allowing for the transfer of fluids such as coolant, fuel, or hydraulic fluid. Its function is to provide a secure and leak-free connection, ensuring that the fluid systems operate efficiently and reliably 2.

Key Features

The design and construction of the 3872294 Pipe Connector include features that enhance its performance and durability. It is made from materials that can withstand the pressures and temperatures encountered in commercial truck applications. The connector type and any unique attributes contribute to its ability to maintain a secure seal and resist corrosion and wear 3.

Benefits

The 3872294 Pipe Connector offers several advantages, including improved fluid transfer efficiency, durability, and reliability. These benefits are particularly important in the demanding environments that commercial trucks often operate in, where components must withstand significant stress and exposure to various elements.

Installation Considerations

When installing the 3872294 Pipe Connector, it is important to follow guidelines and best practices to ensure proper sealing and connection integrity. This includes using the necessary tools, preparing the connection points, and verifying that the connector is securely fastened. Attention to detail during installation can prevent leaks and ensure the connector functions as intended.

Maintenance and Troubleshooting

Regular maintenance practices can help ensure the longevity and performance of the 3872294 Pipe Connector. This includes inspecting the connector for signs of wear or damage and addressing any issues promptly. Common problems may include leaks or corrosion, which can often be resolved through proper maintenance and, if necessary, replacement of the connector.

Compatibility and Applications

The 3872294 Pipe Connector is designed for use in specific types of trucks and fluid systems. It is important to verify compatibility with the truck’s make and model to ensure optimal performance and integration within the fluid system.

Safety Considerations

When working with the 3872294 Pipe Connector, it is important to observe safety guidelines and precautions. This includes handling fluids under pressure with care and ensuring that all connections are secure to prevent leaks or other hazards.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and automotive components. The company has a history of developing and producing high-quality parts, including the 3872294 Pipe Connector, which is designed to meet the rigorous demands of commercial truck applications.

Role of Part 3872294 Pipe Connector in Engine Systems

The 3872294 Pipe Connector is an integral component in the orchestration of various engine systems, ensuring seamless fluid dynamics and thermal management. It facilitates the connection between the Aftercooler Core and the Aftercooler Plumbing, allowing for efficient cooling of the compressed air before it enters the engine. This connection is vital for maintaining optimal air temperature, which directly influences engine performance and longevity.

In the Arrangement of Radiator Plumbing, the Pipe Connector plays a significant role by linking the Radiator to the broader Cooling System. This ensures that the engine’s heat is effectively dissipated, preventing overheating and potential damage to engine components.

When integrated with the Cleaner Air Connection, the Pipe Connector aids in the filtration process by ensuring a secure and leak-free pathway for air to travel from the air filter to the engine intake. This is essential for maintaining engine efficiency and reducing wear on internal components.

The Pipe Connector also interfaces with the LTA Pump and the Cooler, creating a robust connection that allows for the circulation of Torque Converter Oil. This is important for maintaining the proper operation of the torque converter, which is a key component in the transmission system.

In the context of the Engine Cooling System Kit and the Engine Parts Kit, the Pipe Connector serves as a critical junction point. It ensures that all components within these kits are properly connected, allowing for the efficient circulation of Engine Coolant throughout the system. This is essential for maintaining the engine’s operating temperature within safe limits.

The Pipe Connector is also utilized in the Kit Connection Heat Exchanger, where it facilitates the transfer of heat between fluids. This is a key aspect of thermal management in engine systems, helping to maintain optimal operating conditions.

In the Mounting Connection Aftercooler, the Pipe Connector ensures that the Aftercooler is securely attached to the engine, allowing for efficient cooling of the compressed air. This is important for maintaining engine performance and preventing overheating.

The Pipe Connector is also used in the Plumbing Aftercooler Water, Plumbing Heat Exchanger, and Plumbing Radiator systems. In these applications, it ensures that water and other fluids are properly circulated throughout the system, aiding in the cooling process and maintaining engine efficiency.

Finally, the Pipe Connector is used in the Water Bypass Tee and Water Bypass Tube, where it facilitates the bypass of water around certain components when necessary. This is important for maintaining system flexibility and ensuring that the engine can operate efficiently under a variety of conditions.

Conclusion

The Cummins 3872294 Pipe Connector is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation of various engine systems. Its design and features contribute to its durability and performance, making it an essential part for maintaining the integrity and efficiency of truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.