This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3892057 Plain Pipe Nipple is a component manufactured by Cummins, a well-established name in the commercial truck industry. This part is designed for use in commercial trucks, where it serves a specific function within the vehicle’s fluid systems.

Basic Concepts of Plain Pipe Nipples

A plain pipe nipple is a short pipe fitting with male threads on both ends. It is commonly used in fluid systems to connect two components, allowing for the transfer of fluids such as fuel, oil, or coolant. In the context of a truck’s systems, plain pipe nipples facilitate the connection between various parts, ensuring a secure and leak-free joint 1.

Role of the 3892057 Plain Pipe Nipple in Truck Operation

The 3892057 Plain Pipe Nipple plays a role in the operation of a commercial truck by connecting different components within the fluid systems. It facilitates the transfer of fluids, ensuring that systems such as the fuel, oil, and coolant circuits function correctly. By providing a reliable connection point, it helps maintain the integrity of these systems 2.

Key Features

The 3892057 Plain Pipe Nipple is characterized by several key features that contribute to its effectiveness and durability. These include its material composition, which is typically made from high-quality steel to withstand the pressures and temperatures within a truck’s fluid systems. The thread type is designed to ensure a secure fit, and the dimensions are standardized to fit within the truck’s existing systems 3.

Benefits of Using the 3892057 Plain Pipe Nipple

Using the 3892057 Plain Pipe Nipple offers several advantages. Its design allows for ease of installation, making it a convenient choice for maintenance and repair tasks. The reliability of the connection it provides ensures that fluid systems operate without leaks. Additionally, its compatibility with various systems within commercial trucks makes it a versatile component 4.

Installation and Usage

Proper installation of the 3892057 Plain Pipe Nipple involves ensuring that the threads are clean and free of debris before connection. It may require the use of thread sealant to prevent leaks. The nipple should be tightened to the manufacturer’s specified torque to ensure a secure fit without over-tightening, which could damage the threads 5.

Troubleshooting Common Issues

Common issues with plain pipe nipples include leaks and corrosion. To address leaks, check the connection for proper tightness and ensure that thread sealant has been applied correctly. Corrosion can be mitigated by using nipples made from corrosion-resistant materials and by regularly inspecting the component for signs of wear or damage 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3892057 Plain Pipe Nipple, regular maintenance is recommended. This includes inspecting the nipple for signs of wear, corrosion, or leaks, and cleaning it as necessary. Replacing the component at recommended intervals or when signs of damage are detected will help maintain the integrity of the truck’s fluid systems 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Cummins Plain Pipe Nipple 3892057 in Engine Applications

The Cummins Plain Pipe Nipple part number 3892057 is a critical component in various engine configurations. This part is designed to provide a secure and leak-proof connection for pipes within the engine system. Its robust construction ensures it can withstand the high pressures and temperatures typical in engine environments.

L10 MECHANICAL Engines

In the L10 MECHANICAL engines, the Plain Pipe Nipple 3892057 is integral to maintaining the integrity of the engine’s piping system. This part is typically used in the connection of exhaust pipes, coolant lines, and other critical fluid pathways. Its precision fit ensures that there are no leaks, which is crucial for maintaining engine efficiency and safety.

Grouped Applications

While the specific application of the Plain Pipe Nipple 3892057 can vary, it is commonly found in the following configurations:

- Exhaust Systems: Ensuring the exhaust gases are efficiently channeled out of the engine.

- Coolant Systems: Providing a secure connection for coolant pipes, which is vital for temperature regulation.

- Fuel Systems: Although less common, it may also be used in fuel line connections to ensure fuel is delivered without leaks.

The versatility of the Plain Pipe Nipple 3892057 makes it a valuable component across different engine models and applications, ensuring reliable performance and longevity.

Role of Part 3892057 Plain Pipe Nipple in Engine Systems

In the context of engine systems, the Part 3892057 Plain Pipe Nipple is utilized to facilitate the connection between various components, ensuring efficient fluid or gas transfer.

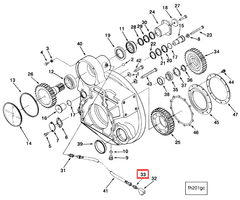

Flywheel Top Level Assembly Housing

Within the flywheel top level assembly housing, the Plain Pipe Nipple is often employed to connect fluid lines that are integral to the cooling or lubrication systems. It provides a secure and leak-proof connection, allowing for the consistent flow of fluids necessary for maintaining optimal operating temperatures and reducing friction within the assembly.

Housing and Flywheel

In the housing that encases the flywheel, the Plain Pipe Nipple plays a significant role in linking hydraulic lines. This is particularly important in systems where hydraulic pressure is used to engage or disengage the flywheel, such as in certain types of clutches. The Nipple ensures that hydraulic fluid is delivered efficiently, contributing to the smooth operation of the flywheel.

Flywheel RPTO (Remote Power Take-Off)

For systems incorporating a Flywheel RPTO, the Plain Pipe Nipple is essential in connecting hydraulic or pneumatic lines that control the power take-off mechanism. This connection is vital for transmitting power from the engine to auxiliary equipment, ensuring that the RPTO operates seamlessly and responds accurately to control inputs.

Overall, the Part 3892057 Plain Pipe Nipple is a fundamental component in these engine systems, providing reliable connections that are essential for the efficient and effective operation of various engine subsystems.

Conclusion

The 3892057 Plain Pipe Nipple is a vital component in the fluid systems of commercial trucks and engines, ensuring secure and leak-free connections. Its robust construction, ease of installation, and compatibility with various systems make it a reliable choice for maintaining the integrity of fluid circuits. Regular maintenance and proper installation practices are key to maximizing the performance and longevity of this Cummins part.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Caines, A. J., Haycock, R. F., & Hillier, J. E. (2004). Automotive Lubricants Reference Book. SAE International.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411184.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411184.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411184.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.