This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

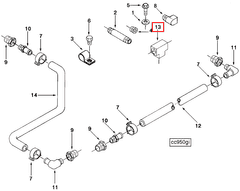

The Cummins 3924635 Female Pipe Tee is a specialized component designed for use in heavy-duty truck systems. Its purpose is to facilitate the distribution or merging of fluid flows within the truck’s piping system. This component is significant due to its role in ensuring efficient fluid management, which is vital for the overall performance and reliability of heavy-duty trucks 1.

Basic Concepts of Female Pipe Tee

A Female Pipe Tee is a type of fitting used in piping systems to connect three pipes together. It consists of a central pipe with two additional pipes branching off at a 90-degree angle. The female designation indicates that the fitting has internal threads, allowing it to connect to male-threaded pipes. In fluid dynamics, a Female Pipe Tee is used to either split a single fluid flow into two separate paths or merge two fluid flows into one. This functionality is crucial in various applications where precise fluid distribution or combination is required 2.

Purpose of the 3924635 Female Pipe Tee in Truck Systems

In the context of heavy-duty trucks, the 3924635 Female Pipe Tee plays a specific role in the operation of the vehicle’s fluid systems. It is used to distribute or merge fluid flows, ensuring that the correct amount of fluid is delivered to different parts of the system. This can include applications such as fuel distribution, coolant circulation, or hydraulic fluid management. By efficiently managing fluid flows, the 3924635 Female Pipe Tee contributes to the overall efficiency and reliability of the truck’s systems 3.

Key Features

This Cummins part is designed with several key features that enhance its performance and durability. These include a robust material composition that can withstand high pressures and temperatures, precise internal threading for secure connections, and a design that ensures smooth fluid flow with minimal resistance. These features contribute to the component’s ability to perform reliably in demanding heavy-duty truck applications.

Benefits of Using the 3924635 Female Pipe Tee

The use of the 3924635 Female Pipe Tee offers several advantages in heavy-duty truck operations. It provides improved fluid management by ensuring that fluid flows are distributed or merged efficiently. This leads to enhanced system efficiency, as the correct amount of fluid is delivered to each component without unnecessary waste or pressure drops. Additionally, the reliability of the 3924635 Female Pipe Tee contributes to the overall dependability of the truck’s fluid systems, reducing the likelihood of failures or inefficiencies.

Installation Considerations

When installing the 3924635 Female Pipe Tee, it is important to follow guidelines and best practices to ensure proper functionality. This includes ensuring proper alignment of the fitting with the pipes it connects to, using the correct torque specifications to secure the connections, and verifying compatibility with other system components. Proper installation is crucial for maintaining the integrity of the fluid system and ensuring the longevity of the fitting.

Maintenance and Troubleshooting

Routine maintenance practices can help ensure the longevity and optimal performance of the 3924635 Female Pipe Tee. This includes regular inspection for signs of wear or damage, cleaning the fitting to remove any debris that may obstruct fluid flow, and tightening connections as needed. In the event of issues such as leaks or blockages, troubleshooting steps may involve checking for proper alignment, ensuring connections are secure, and inspecting for damage to the fitting or connected pipes.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a leader in the diesel engine manufacturing industry. The company is committed to innovation, continuously developing new technologies and solutions to meet the evolving needs of its customers. Cummins’ expertise in engine manufacturing and its dedication to quality and performance make it a trusted name in the automotive industry.

Cummins Female Pipe Tee Part 3924635 Compatibility

The Cummins Female Pipe Tee part number 3924635 is a versatile component that can be integrated into various engine systems. This part is designed to facilitate the connection of pipes in a manner that ensures a secure and leak-proof joint. Here is a detailed look at its compatibility with specific engine models:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ lineup of industrial and heavy-duty diesel engines. The Female Pipe Tee part 3924635 is compatible with these engines due to its robust design and ability to handle the pressure and flow requirements typical of these engine systems. This part is often used in the exhaust systems of these engines, ensuring efficient and reliable operation.

B5.9 G Engine

The B5.9 G engine, another member of Cummins’ extensive engine family, also benefits from the use of the Female Pipe Tee part 3924635. This part is particularly useful in the exhaust and cooling systems of the B5.9 G engine, where it provides a critical connection point for various pipes. Its design ensures that it can withstand the operational stresses of these systems, contributing to the overall durability and performance of the engine.

Grouping for Efficiency

When considering the integration of the Female Pipe Tee part 3924635 into the 4B3.9 and 6B5.9 engines, it is important to note that these engines share many common components and design philosophies. This commonality allows for the efficient use of parts like the Female Pipe Tee, which can be standardized across these models, reducing inventory costs and simplifying maintenance procedures.

By understanding the compatibility and application of the Female Pipe Tee part 3924635 with these engines, technicians and maintenance personnel can ensure that their systems are operating at peak efficiency, with reliable connections that meet the demands of heavy-duty operations.

Role of Part 3924635 Female Pipe Tee in Engine Systems

The 3924635 Female Pipe Tee is an essential component in various engine systems, facilitating the efficient distribution and management of fluids. In the context of an arrangement within an engine, this part allows for the branching of fluid lines, ensuring that multiple components receive the necessary fluid supply without interruption.

In compressor coolant systems, the Female Pipe Tee plays a significant role by enabling the coolant to be directed to different parts of the compressor. This ensures that all critical areas are adequately cooled, maintaining optimal performance and preventing overheating.

Within plumbing systems, the Female Pipe Tee is utilized to split fluid lines, allowing for the distribution of fluids to various engine components. This is particularly important in complex engine setups where multiple systems require fluid supply from a single source.

The integration of the Female Pipe Tee in compr coolant systems enhances the efficiency of coolant distribution. By allowing coolant to be directed to different sections of the compressor, it helps in maintaining consistent temperatures across the system, which is vital for the longevity and reliability of the engine.

Overall, the 3924635 Female Pipe Tee is a versatile component that contributes to the smooth operation of engine systems by ensuring proper fluid distribution and management.

Conclusion

The Cummins 3924635 Female Pipe Tee is a critical component in heavy-duty truck and engine systems, ensuring efficient fluid management and distribution. Its robust design, precise threading, and compatibility with various engine models make it a reliable choice for maintaining the performance and reliability of these systems. Proper installation, maintenance, and understanding of its role in different engine applications are essential for maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.