This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

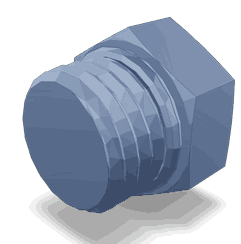

The Cummins 3964302 Pipe Plug is a component designed to ensure the integrity of fluid systems in commercial trucks. Its role is to prevent fluid leakage, thereby maintaining the efficiency and reliability of the truck’s operations. Understanding its purpose and significance is fundamental for maintaining the vehicle’s performance and longevity.

Basic Concepts of Pipe Plugs

A pipe plug is a device used in fluid systems to seal openings and prevent the escape of liquids or gases. It operates by fitting securely into a pipe or fitting, creating a barrier that stops fluid flow. This function is vital in maintaining system pressure and preventing contamination or loss of fluid, which can lead to system failure or inefficiency 1.

Purpose of the Cummins 3964302 Pipe Plug

The Cummins 3964302 Pipe Plug is specifically designed to fit into designated openings within a truck’s fluid systems. Its primary function is to seal these openings, preventing fluid leakage that could compromise the system’s operation. By ensuring a tight seal, it helps maintain the system’s pressure and efficiency, contributing to the overall performance of the truck.

Key Features

This Cummins part is characterized by its robust design and material composition, which includes high-quality metals that resist corrosion and wear. These materials ensure that the plug can withstand the harsh conditions often encountered in commercial truck operations. Additionally, its design allows for a secure fit, enhancing its ability to prevent fluid leakage effectively.

Benefits of Using the Cummins 3964302 Pipe Plug

Utilizing this part offers several advantages. It contributes to improved system integrity by ensuring that fluid systems remain sealed and operational. This can lead to reduced maintenance needs, as the risk of fluid leakage and associated damages is minimized. Furthermore, by maintaining system efficiency, it enhances the operational performance of the truck.

Installation Process

Installing the Cummins 3964302 Pipe Plug requires careful attention to ensure a secure fit. The process involves cleaning the fitting area to remove any debris or old sealant, applying a compatible sealant if necessary, and then inserting the plug into the fitting. It is important to use the appropriate tools to ensure the plug is seated correctly without damaging the fitting or the plug itself.

Troubleshooting Common Issues

Common issues with pipe plugs include signs of wear, leakage, or improper installation. Wear can be identified by examining the plug for signs of corrosion or physical damage. Leakage may be indicated by fluid stains or drops near the plug’s location. Improper installation can often be corrected by removing the plug, cleaning the fitting, and reinstalling it with the correct procedure and tools.

Maintenance Tips

Regular maintenance of the Cummins 3964302 Pipe Plug is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the fitting area to prevent debris accumulation, and ensuring the plug remains securely in place. Following these maintenance procedures can help prevent issues before they arise.

Compatibility and Applications

The Cummins 3964302 Pipe Plug is designed for use in various truck models and systems, demonstrating its versatility and widespread application. Its compatibility with different systems allows it to be a valuable component in maintaining the fluid systems of commercial trucks across a range of applications.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history of innovation and excellence provides a strong foundation for the quality and performance of components like the 3964302 Pipe Plug, ensuring that it meets the high standards expected in commercial truck operations.

Cummins Engine Pipe Plug 3964302 Compatibility

The Cummins Pipe Plug part number 3964302 is designed to fit seamlessly with several of Cummins’ engine models. This part is integral to the engine’s operation, ensuring that the exhaust system remains sealed and efficient. Here is a detailed look at the compatibility of this part with various Cummins engines:

QSB5.9 CM850 and QSC8.3 CM850(CM2850)

The Pipe Plug 3964302 is compatible with the QSB5.9 CM850 and QSC8.3 CM850(CM2850) engines. These engines are known for their robust performance and reliability, often used in various industrial and agricultural applications. The pipe plug ensures that the exhaust system’s integrity is maintained, preventing leaks and ensuring optimal engine performance.

QSB6.7 M CM2250

Similarly, the QSB6.7 M CM2250 engine also supports the use of the Pipe Plug 3964302. This engine is part of Cummins’ lineup of medium-duty diesel engines, offering a balance of power and efficiency. The pipe plug’s role in this engine is crucial for maintaining the exhaust system’s seal, which is essential for the engine’s overall efficiency and longevity.

Ensuring Compatibility and Performance

When installing the Pipe Plug 3964302 in any of the aforementioned engines, it is essential to ensure that the part is correctly fitted. Proper installation is key to maintaining the engine’s performance and preventing potential issues such as exhaust leaks or reduced efficiency. Cummins has designed this part to be a reliable component, ensuring that it fits snugly and functions as intended across these engine models.

Role of Part 3964302 Pipe Plug in Various Engine Systems

The 3964302 Pipe Plug is a component in several engine systems, ensuring the integrity and efficiency of these systems. Its applications span across various critical areas, including:

Connection Points

In engine systems, the 3964302 Pipe Plug is often used at connection points where fluid or gas transfer occurs. It ensures a secure seal, preventing leaks that could lead to system inefficiencies or failures. This is particularly important in high-pressure systems where even minor leaks can have significant consequences.

Exhaust Outlet

At the exhaust outlet, the 3964302 Pipe Plug plays a role in sealing off sections of the exhaust system during maintenance or repair. This prevents contaminants from entering the system and ensures that diagnostic tests are accurate. It also aids in the safe and efficient disassembly and reassembly of the exhaust components.

Exhaust Riser Kit

Within an exhaust riser kit, the 3964302 Pipe Plug is used to seal off ports or passages that are not in use. This helps maintain the structural integrity of the riser kit and ensures that the exhaust flow is directed correctly, enhancing the overall performance of the exhaust system.

Plumbing Systems

In the context of engine plumbing, the 3964302 Pipe Plug is utilized to cap off sections of the plumbing that are not operational or are being temporarily bypassed. This is vital in complex engine systems where multiple fluid lines are in use, ensuring that the system remains pressurized and functions as intended.

Radiator Systems

For radiator systems, the 3964302 Pipe Plug is employed to seal off coolant passages during repairs or upgrades. This prevents coolant loss and maintains the system’s pressure, which is essential for efficient heat dissipation and engine cooling.

In each of these applications, the 3964302 Pipe Plug contributes to the reliability and performance of the engine system, ensuring that all components work in harmony to deliver optimal engine operation.

Conclusion

The Cummins 3964302 Pipe Plug is a critical component in maintaining the integrity and efficiency of fluid systems in commercial trucks. Its robust design, compatibility with various engine models, and versatile applications make it a valuable asset in ensuring the reliability and performance of commercial truck operations. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the longevity and efficiency of the vehicle.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.