This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

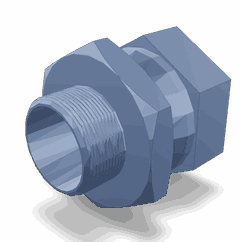

The Cummins 4010926 Reducing Pipe Adapter is designed to facilitate connections between pipes of different diameters within the fluid systems of commercial trucks. It ensures smooth and efficient operation by allowing for the seamless transition of fluid flow between pipes of varying sizes.

Basic Concepts of Reducing Pipe Adapters

Reducing pipe adapters are fittings used in fluid systems to connect pipes with different diameters. They provide a gradual reduction in diameter, helping maintain the flow rate and pressure of the fluid as it moves through the system. These adapters are commonly used in automotive and industrial applications to ensure compatibility between different sections of piping and to optimize the performance of fluid systems 1.

Purpose of the Cummins 4010926 Reducing Pipe Adapter

The Cummins 4010926 Reducing Pipe Adapter connects pipes of different diameters in a truck’s fluid system, facilitating the uninterrupted flow of fluids such as coolant or fuel. This ensures the system operates efficiently by maintaining consistent fluid dynamics 2.

Key Features

The Cummins 4010926 Reducing Pipe Adapter features a robust material composition designed to withstand the pressures and temperatures of commercial truck fluid systems. It has precise design specifications for a secure fit and unique attributes that contribute to its effectiveness in facilitating fluid flow 3.

Benefits of Using the Cummins 4010926 Reducing Pipe Adapter

Using this Cummins part offers several advantages, including improved system efficiency by ensuring a smooth transition between pipes of different diameters. It reduces the risk of leaks and enhances compatibility with various pipe sizes, making it a versatile component within the truck’s fluid system 4.

Installation Considerations

When installing the Cummins 4010926 Reducing Pipe Adapter, it is important to follow guidelines and best practices to ensure a secure and efficient connection. This includes using the necessary tools for a proper fit, adhering to recommended procedures for installation, and being aware of potential challenges such as ensuring the adapter is correctly aligned and tightened to the appropriate specifications 5.

Troubleshooting Common Issues

Common issues with the Cummins 4010926 Reducing Pipe Adapter include leaks or improper fitting. Troubleshooting involves checking the adapter for any signs of damage or misalignment, ensuring it is correctly installed, and making any necessary adjustments to secure the connection. Addressing these issues promptly helps maintain the efficiency and reliability of the truck’s fluid system 6.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 4010926 Reducing Pipe Adapter, regular maintenance is recommended. This includes inspecting the adapter for any signs of wear or damage, cleaning it to remove any buildup that could affect its function, and following replacement guidelines to ensure it continues to operate effectively within the truck’s fluid system 7.

Compatibility and Applications

The Cummins 4010926 Reducing Pipe Adapter is typically used within commercial truck systems where compatibility between different pipe sizes is required. Its design and specifications make it suitable for a range of applications within these systems, ensuring that it can effectively connect and facilitate the flow of fluids between pipes of varying diameters 8.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to excellence, Cummins continues to be a leading provider of components and systems for commercial vehicles, including the Cummins 4010926 Reducing Pipe Adapter 9.

Cummins Reducing Pipe Adapter 4010926 Compatibility

The Cummins Reducing Pipe Adapter part number 4010926 is designed to fit seamlessly with the QSV81G and QSV91G engines. This adapter is crucial for ensuring proper fluid flow and pressure within the engine’s system, maintaining optimal performance and efficiency.

QSV81G Engine

For the QSV81G engine, the Reducing Pipe Adapter 4010926 is engineered to interface with specific components within the engine’s hydraulic or fuel system. Its precision fit ensures that there are no leaks or inefficiencies, which could otherwise lead to performance degradation or increased wear on engine parts 10.

QSV91G Engine

Similarly, the QSV91G engine benefits from the use of the Cummins Reducing Pipe Adapter 4010926. This part is designed to connect various pipes and fittings within the engine’s system, ensuring that the fluid dynamics are maintained at the required levels. The adapter’s robust construction guarantees durability and reliability, even under the demanding conditions typical of heavy-duty engines 11.

Grouping of Engines

Both the QSV81G and QSV91G engines fall under the category of high-performance, heavy-duty engines, often used in industrial and commercial applications. The Reducing Pipe Adapter 4010926 is specifically crafted to meet the stringent requirements of these engines, providing a critical link in the engine’s overall system integrity 12.

Role of Part 4010926 Reducing Pipe Adapter in Engine Systems

The part 4010926 Reducing Pipe Adapter is instrumental in ensuring seamless integration and functionality within various engine systems. Specifically, it plays a significant role in the coolant heater starting aid system.

Coolant Heater Starting Aid System

In the coolant heater starting aid system, the Reducing Pipe Adapter facilitates the connection between different diameter pipes. This adapter ensures that the coolant flow is uninterrupted and efficiently regulated. By reducing the diameter of the pipe where necessary, it allows for precise control over the coolant distribution, which is essential for maintaining optimal engine temperature during startup, especially in colder climates 13.

Integration with Coolant Heater

The adapter is also vital in the coolant heater system. It ensures that the heated coolant is effectively circulated through the engine block and other critical components. This efficient circulation helps in reducing the viscosity of the engine oil, making it easier for the engine to start and reach operating temperature more quickly. The Reducing Pipe Adapter helps in maintaining the correct pressure and flow rate of the coolant, which is necessary for the heater to function effectively 14.

Overall System Efficiency

By ensuring proper connections and flow rates, the Reducing Pipe Adapter contributes to the overall efficiency of the engine systems. It helps in preventing leaks and maintaining consistent pressure throughout the coolant system, which is essential for the longevity and performance of the engine. The adapter’s role in these systems underscores its importance in maintaining the engine’s operational integrity and efficiency 15.

Conclusion

The Cummins 4010926 Reducing Pipe Adapter is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its design, compatibility, and role in maintaining system integrity make it an essential part for any truck owner or technician to understand and maintain.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613007, ISF2.8 CM2220 EC.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613007, ISF2.8 CM2220 EC.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual, Bulletin Number 5613007, ISF2.8 CM2220 EC.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.