This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

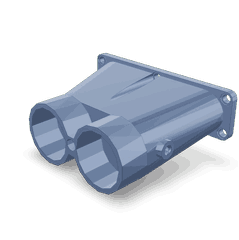

The Flanged Pipe Adapter 4012700, manufactured by Cummins, is a critical component in the commercial truck industry. This adapter facilitates the connection between different sections of a truck’s piping system, ensuring a secure and efficient flow of fluids or gases. Its design is integral to maintaining the operational integrity of various truck systems.

Basic Concepts of Flanged Pipe Adapters

Flanged pipe adapters are fittings used to connect pipes or other components in a piping system. They feature flanges—discs with holes that align with the pipe ends—which are bolted together to create a seal. These adapters are widely used across industries for their ability to provide a robust connection that can be easily disassembled for maintenance or modifications 1. In commercial trucks, they are particularly valuable for their reliability and ease of use in high-stress environments.

Purpose of the 4012700 Flanged Pipe Adapter in Truck Operations

This Cummins part enables the connection of different pipe sections within the truck’s fluid systems, including fuel, coolant, and other critical fluids. By providing a secure and leak-proof connection, it helps maintain the efficiency and safety of the truck’s operations. Its integration into the truck’s systems is designed to enhance performance and reliability, ensuring that the truck can operate under various conditions without compromising on efficiency 2.

Key Features of the 4012700 Flanged Pipe Adapter

The Flanged Pipe Adapter is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design specifications of the adapter include precise flange dimensions and bolt patterns that ensure a secure fit and seal. Additionally, it may feature unique attributes such as reinforced flanges or specialized coatings to further enhance its performance and durability 3.

Benefits of Using the 4012700 Flanged Pipe Adapter

Incorporating this part into truck systems offers several advantages. It contributes to improved efficiency by ensuring a secure and leak-proof connection between pipe sections. This reliability reduces the risk of system failures and enhances the overall performance of the truck. Additionally, the adapter’s design facilitates ease of maintenance, allowing for quick disassembly and reassembly when needed. This feature not only saves time during maintenance operations but also extends the lifespan of the truck’s piping system.

Installation and Integration

Proper installation of the 4012700 is crucial for its effective operation. It should be integrated into the truck’s systems following manufacturer guidelines to ensure a secure and efficient connection. Preparatory steps may include cleaning the connection points and ensuring that all components are free from debris. Careful alignment of the flanges and the use of the correct torque specifications for bolting are also important considerations during installation.

Troubleshooting Common Issues

Common problems with the Flanged Pipe Adapter may include leaks or loose connections. Troubleshooting these issues involves checking the integrity of the seal, ensuring that the flanges are properly aligned, and that the bolts are tightened to the correct specifications. In cases where leaks persist, inspecting the adapter for signs of wear or damage and replacing any compromised components may be necessary.

Maintenance Tips

Regular maintenance of the 4012700 is key to ensuring its longevity and optimal performance. This includes periodic inspection of the connection points for signs of wear, corrosion, or leaks. Cleaning the flanges and bolts, and reapplying any necessary sealants or coatings, can help maintain the integrity of the connection. Additionally, following the manufacturer’s recommended maintenance schedule for torque checks and component inspections will contribute to the adapter’s reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name among truck manufacturers and operators worldwide.

Cummins Flanged Pipe Adapter 4012700 Compatibility with QSV Engines

The Cummins Flanged Pipe Adapter 4012700 is designed to seamlessly integrate with specific engine models, ensuring optimal performance and reliability. This adapter is particularly compatible with the QSV81G and QSV91G engines, providing a crucial connection point for various fluid systems within the engine.

QSV81G and QSV91G Engines

For the QSV81G and QSV91G engines, the 4012700 plays a pivotal role in maintaining the integrity of the engine’s fluid pathways. This adapter is engineered to fit precisely, ensuring that connections are tight and secure, which is essential for preventing leaks and maintaining system efficiency. The design of the adapter allows for easy installation and removal, facilitating maintenance and repairs.

The flanged pipe adapter is a critical component in the overall architecture of these engines, providing a reliable interface for connecting pipes and hoses to the engine’s fluid systems. Its robust construction ensures that it can withstand the high pressures and temperatures typical of engine operations, contributing to the longevity and dependability of the engine.

Role of Part 4012700 Flanged Pipe Adapter in Engine Systems

The 4012700 is an essential component in the integration and functionality of various engine systems. Its primary role is to facilitate the connection between different parts, ensuring a secure and efficient transfer of fluids or gases.

In the context of the drive system, the Flanged Pipe Adapter is used to connect the drive components, allowing for the smooth transmission of power. This ensures that the drive operates without leaks or disruptions, maintaining the overall efficiency of the engine.

When considering the accessory drive, the adapter plays a significant role in linking the accessory components to the main drive system. This connection is vital for the operation of accessories such as pumps, compressors, and other auxiliary devices that rely on a consistent flow of fluids or gases.

In the front gear train accessory setup, the Flanged Pipe Adapter ensures that the accessory components are properly aligned and connected. This is important for the precise operation of the gear train, which relies on accurate fluid dynamics to function correctly.

Overall, the 4012700 is a key element in maintaining the integrity and performance of engine systems by providing reliable connections between critical components.

Conclusion

The Flanged Pipe Adapter 4012700 by Cummins is a vital component in the commercial truck industry, ensuring secure and efficient connections within the truck’s fluid systems. Its robust design, ease of maintenance, and compatibility with specific engine models like the QSV81G and QSV91G make it an indispensable part for maintaining the performance and reliability of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.