This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

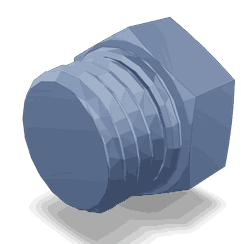

The Cummins 4078168 Pipe Plug is a component designed for use in commercial trucks. Its primary function is to seal openings in fluid systems, ensuring that liquids such as engine oil, transmission fluid, or coolant do not escape. This part plays a role in maintaining the integrity of the fluid systems within heavy-duty trucks, contributing to their overall performance and reliability 1.

Basic Concepts of Pipe Plugs

A pipe plug is a device used to seal the end of a pipe or a fitting in a fluid system. Its general function is to prevent the leakage of fluids, which is vital for the proper operation of various systems in vehicles. Pipe plugs operate by fitting securely into an opening, creating a barrier that stops fluid from escaping. This is achieved through a tight seal, often enhanced by threading or other sealing mechanisms 2.

Purpose of the Cummins 4078168 Pipe Plug

The Cummins 4078168 Pipe Plug is specifically designed to serve as a sealing component in the fluid systems of heavy-duty trucks. It is applied in both engine and transmission systems to ensure that fluids remain contained within their respective systems. By preventing leaks, this pipe plug helps maintain the efficiency and reliability of these systems, contributing to the overall performance of the truck.

Key Features

The Cummins 4078168 Pipe Plug is characterized by its robust design and material composition. It is typically made from high-quality materials that offer resistance to corrosion and wear, ensuring durability in demanding environments. The design of the plug may include threading or other features that enhance its sealing capabilities, providing a secure fit in the openings it is intended to seal.

Benefits

Using the Cummins 4078168 Pipe Plug offers several benefits. It contributes to improved system integrity by effectively sealing openings in fluid systems, which helps prevent leaks. This, in turn, reduces the need for frequent maintenance and repairs, leading to enhanced operational efficiency. The durability of the plug also means that it can withstand the rigors of heavy-duty truck operation, providing long-term reliability.

Installation Process

Installing the Cummins 4078168 Pipe Plug requires careful attention to ensure a secure fit. The process involves cleaning the opening where the plug will be installed to remove any debris or old sealant. The plug is then threaded into the opening by hand until it is snug, after which a wrench may be used to tighten it further. It is important to avoid over-tightening, as this can damage the plug or the fitting. Following the manufacturer’s guidelines for torque specifications ensures a proper seal without causing damage.

Troubleshooting Common Issues

Common issues with pipe plugs include leaks and corrosion. If a leak is detected, the first step is to ensure that the plug is properly installed and tightened. If the plug appears to be in good condition and correctly installed, the issue may lie elsewhere in the system. Corrosion can be addressed by replacing the plug if it is damaged or by applying a compatible sealant to enhance the seal. Regular inspections can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To prolong the life of the Cummins 4078168 Pipe Plug, regular maintenance is recommended. This includes periodic inspections to check for signs of wear, corrosion, or leaks. Cleaning the plug and the surrounding area can prevent the buildup of debris that may compromise the seal. Following the manufacturer’s guidelines for maintenance and replacement intervals ensures that the plug continues to perform effectively.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and stationary applications, as well as filtration and emission solutions. Cummins is dedicated to powering a more prosperous world by providing reliable and efficient power solutions.

Cummins Pipe Plug 4078168 Compatibility with K38 and K50 Engines

The Cummins Pipe Plug part number 4078168 is designed to fit seamlessly within the K38 and K50 engine families. This part is integral to the engine’s operation, ensuring that the exhaust system is properly sealed and maintained.

For the K38 engine, the pipe plug is specifically engineered to fit into the exhaust manifold, providing a secure seal that prevents leaks and maintains optimal exhaust flow. This ensures that the engine operates efficiently and reliably, reducing the risk of performance issues and extending the engine’s lifespan.

Similarly, in the K50 engine, the pipe plug is designed to fit into the exhaust system, ensuring a tight seal that is crucial for maintaining the engine’s performance. The precise fit and high-quality construction of the part ensure that it can withstand the high temperatures and pressures within the exhaust system, providing long-lasting durability and reliability.

Both engines benefit from the use of this pipe plug, as it helps to maintain the integrity of the exhaust system and supports the overall efficiency and performance of the engine. The compatibility of the part with both the K38 and K50 engines highlights its versatility and importance in ensuring the smooth operation of these engines.

Understanding the Role of Part 4078168 Pipe Plug in Engine Systems

Part 4078168, a Pipe Plug, is a component in various engine systems, particularly those involving fluid dynamics and hydraulic operations. Its primary function is to seal and secure openings within piping systems, ensuring the integrity and efficiency of the system.

Integration with Pumps

In pump systems, the 4078168 Pipe Plug is utilized to seal off unused ports or openings. This is particularly important in multi-port pumps where not all ports are in use at a given time. By sealing these ports, the Pipe Plug prevents fluid leakage and maintains system pressure, which is vital for the pump’s performance and longevity.

Application in Raw Water Systems

For raw water systems, the 4078168 Pipe Plug plays a significant role in maintaining the purity and pressure of the water being transported. In systems where raw water is used for cooling or other processes, the Pipe Plug ensures that there are no unauthorized leaks or entries into the system, which could contaminate the water or reduce its pressure.

Seawater Pump Systems

In seawater pump systems, the 4078168 Pipe Plug is employed to seal off sections of the pump that are not in use. Seawater systems are particularly susceptible to corrosion and blockages, and the Pipe Plug helps in preventing seawater from entering unused parts of the system, thereby reducing the risk of corrosion and maintaining the efficiency of the pump.

Seawater Pipe Mount Systems

When it comes to seawater pipe mount systems, the 4078168 Pipe Plug is used to seal connections and openings in the pipe mounts. This is essential in maintaining the structural integrity of the pipe mounts and ensuring that seawater does not seep into areas where it could cause damage or reduce the effectiveness of the system.

Conclusion

In summary, the Cummins 4078168 Pipe Plug is a versatile component that enhances the functionality and reliability of various engine systems by providing a secure seal in piping and pump systems. Its application across different components underscores its importance in maintaining system efficiency and preventing potential issues related to fluid leakage and contamination.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.