This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

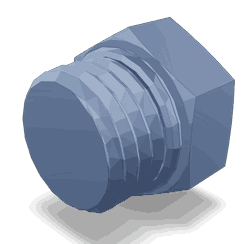

The Cummins 5261993 Pipe Plug is a component designed for use in heavy-duty truck maintenance and operation. Its role is to ensure the integrity of fluid systems within these vehicles, preventing leaks and contamination that could lead to system failure or reduced efficiency.

Basic Concepts of Pipe Plugs

A pipe plug is a device used in fluid systems to seal openings, thereby preventing the escape of fluids or the ingress of contaminants. It operates by fitting securely into a pipe or fitting, creating a barrier that maintains system pressure and fluid levels. This is crucial for the efficient operation of various vehicle systems, including fuel, coolant, and hydraulic systems 1.

Purpose of the Cummins 5261993 Pipe Plug

The Cummins 5261993 Pipe Plug is specifically designed to play a role in the fluid management systems of trucks. It is positioned in areas where fluid systems require sealing, such as at the ends of pipes or in openings where components have been removed for maintenance or repair. This plug is engineered to manage a variety of fluids, ensuring that the system remains sealed and operational.

Key Features

The Cummins 5261993 Pipe Plug is constructed from materials that offer durability and resistance to the corrosive effects of various fluids. Its design includes features that ensure a tight fit, reducing the risk of leaks. The material and design characteristics contribute to its performance and longevity in demanding environments.

Benefits

Utilizing the Cummins 5261993 Pipe Plug offers several advantages. It contributes to the integrity of the fluid system by providing a reliable seal, which can lead to reduced maintenance needs. Additionally, by preventing leaks and contamination, it helps maintain operational efficiency, ensuring that the truck performs optimally 2.

Installation Process

Installing the Cummins 5261993 Pipe Plug involves several steps to ensure a proper fit. First, the area where the plug will be installed should be cleaned to remove any debris or old sealant. The plug is then inserted into the opening, ensuring it is seated correctly. Tools may be required to achieve the necessary tightness, and it is important to follow manufacturer guidelines to avoid over-tightening, which could damage the plug or the fitting.

Troubleshooting Common Issues

Common issues with pipe plugs include leaks and corrosion. Leaks may occur due to improper installation or wear over time. Corrosion can be a result of exposure to certain fluids or environmental conditions. Diagnosing these issues involves inspecting the plug and the surrounding area for signs of damage or wear. Resolution may require cleaning, re-sealing, or replacing the plug.

Maintenance Tips

To prolong the life of the Cummins 5261993 Pipe Plug, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the plug and its surrounding area to prevent buildup, and ensuring that it remains securely fitted. Following these practices can help maintain the integrity of the fluid system and the efficiency of the truck.

Compatibility and Usage

The Cummins 5261993 Pipe Plug is designed for use in specific types of trucks and fluid systems. It is important to consult the manufacturer’s guidelines for compatibility and any specific usage instructions to ensure optimal performance and safety.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its products, including the Cummins 5261993 Pipe Plug.

Cummins Engine Part 5261993: Pipe Plug Compatibility

The Cummins part number 5261993, identified as a Pipe Plug, is a critical component that fits seamlessly within the engine systems of the QSB5.9 CM850 and QSM11 CM570 engines. This part is integral to maintaining the integrity and functionality of the engine’s exhaust and cooling systems.

QSB5.9 CM850

The QSB5.9 CM850 engine, known for its robust performance and reliability, utilizes the Pipe Plug part number 5261993 to ensure that the exhaust and coolant pathways remain sealed. This particular engine is often employed in heavy-duty applications, where durability and efficiency are paramount. The Pipe Plug’s role in this engine is to prevent leaks and maintain the necessary pressure within the system, contributing to the overall efficiency and longevity of the engine.

QSM11 CM570

Similarly, the QSM11 CM570 engine benefits from the use of the Pipe Plug part number 5261993. This engine is designed for applications that require a balance of power and fuel efficiency. The Pipe Plug in this engine ensures that the internal pathways are properly sealed, which is crucial for maintaining optimal performance and preventing any potential damage from leaks. The precision engineering of this part ensures that it fits perfectly within the engine’s design, providing a reliable seal that is essential for the engine’s operation.

Grouping the Engines

Both the QSB5.9 CM850 and QSM11 CM570 engines share a common requirement for the Pipe Plug part number 5261993. This part is designed to fit into the specific configurations of these engines, ensuring that they operate efficiently and safely. The compatibility of this part across these engines highlights its importance in maintaining the structural and functional integrity of the engine systems.

Role of Part 5261993 Pipe Plug in Engine Systems

The part 5261993 Pipe Plug is an essential component in various engine systems, ensuring the integrity and efficiency of the overall engine performance.

In the aftercooler system, the Pipe Plug is utilized to seal off specific passages or ports that are not in use. This helps maintain the pressure differentials necessary for efficient cooling of the compressed air, which is vital for optimal engine operation.

Within the turbocharger arrangement, the Pipe Plug plays a significant role by sealing unused ports or passages. This ensures that the turbocharger operates within its designed parameters, preventing any unwanted air leaks that could compromise boost pressure and overall efficiency.

In the oil cooler system, the Pipe Plug is employed to block off ports that are not required during specific operational conditions. This aids in directing the flow of oil through the cooler more effectively, ensuring that the oil maintains the appropriate temperature for lubricating engine components.

During product installation, the Pipe Plug is often used to temporarily seal off components or passages that are not yet connected. This practice is common in the assembly line to prevent contaminants from entering the system before final connections are made.

In summary, the part 5261993 Pipe Plug is a versatile component that enhances the functionality and reliability of various engine systems by ensuring that only the necessary passages are open during operation.

Conclusion

The Cummins 5261993 Pipe Plug is a vital component in the maintenance and operation of heavy-duty trucks. Its design and features ensure the integrity of fluid systems, preventing leaks and contamination. Proper installation, maintenance, and understanding of its compatibility and usage are key to maximizing its benefits and ensuring the efficient operation of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.