This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5289535 Pipe Plug is a critical component designed for use in commercial trucks. It serves to seal openings in various fluid systems within the truck, ensuring that fluids remain contained and do not leak out. This part plays a role in maintaining the integrity of the truck’s fluid systems, contributing to overall operational efficiency and safety 4.

Basic Concepts of Pipe Plugs

Pipe plugs are components used in fluid systems to seal openings where fluid flow is not required. They are essential for preventing leaks and maintaining system pressure. In the context of heavy-duty trucks, pipe plugs are employed in various systems, including fuel, hydraulic, and coolant systems. They operate by fitting snugly into openings, creating a barrier that prevents fluid escape 1.

Purpose of the Cummins 5289535 Pipe Plug

The Cummins 5289535 Pipe Plug is specifically designed to seal openings in the truck’s fluid systems. Its primary function is to prevent fluid leaks, which can lead to system inefficiencies and potential safety hazards. By ensuring that fluids remain within the system, this pipe plug contributes to the reliable operation of the truck 2.

Key Features

The Cummins 5289535 Pipe Plug is constructed from durable materials, ensuring it can withstand the harsh conditions encountered in commercial truck operations. Its design includes a tight-fitting seal that effectively prevents fluid leakage. Additionally, the plug may feature anti-corrosion coatings or treatments to enhance its longevity in demanding environments 3.

Benefits of Using the Cummins 5289535 Pipe Plug

Incorporating the Cummins 5289535 Pipe Plug into truck maintenance offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The plug’s design allows for easy installation, minimizing downtime during maintenance procedures. Furthermore, its effective sealing capability contributes to the overall efficiency and safety of the truck’s fluid systems 4.

Installation Process

Installing the Cummins 5289535 Pipe Plug requires following a series of steps to ensure proper fitting and sealing. Begin by cleaning the opening where the plug will be installed to remove any debris or contaminants. Use the appropriate tools to insert the plug, ensuring it fits snugly without forcing it. It is important to observe safety precautions during installation, such as wearing protective gloves and eyewear 1.

Troubleshooting Common Issues

Typical problems associated with pipe plugs include leaks and corrosion. If a leak is detected, inspect the plug for signs of damage or improper fitting. Corrosion can be addressed by cleaning the affected area and applying a corrosion-resistant coating. Regular inspections can help identify issues early, allowing for timely repairs or replacements 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5289535 Pipe Plug, regular maintenance is recommended. Inspect the plug during routine maintenance checks for signs of wear, corrosion, or leaks. Cleaning the plug and its surrounding area can prevent buildup that may lead to issues. Following these maintenance practices can contribute to the reliable operation of the truck’s fluid systems 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of heavy-duty applications, including the Cummins 5289535 Pipe Plug 4.

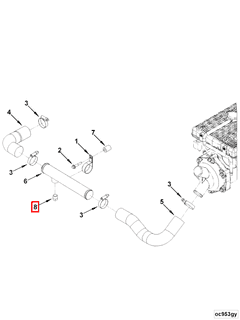

Role of Part 5289535 Pipe Plug in Engine Systems

In engine systems, the Cummins 5289535 Pipe Plug is utilized to ensure the integrity and efficiency of various components and connections. It plays a significant role in the following areas:

Raw Water Outlet and Pump

The Pipe Plug is often used at the raw water outlet to prevent debris and contaminants from entering the system. When installed at the pump, it helps maintain a clean and unobstructed flow of raw water, which is essential for the pump’s performance and longevity 1.

Cooler and Heat Exchanger

In coolers and heat exchangers, the Pipe Plug is employed to seal off unused or maintenance ports. This ensures that the cooling process remains efficient by preventing any unwanted leaks or disruptions in the flow of coolant or raw water 2.

Marine Gear Oil and Plumbing

For marine gear oil systems, the Pipe Plug is used to seal connections and prevent the escape of oil, which is vital for maintaining lubrication and reducing wear on moving parts. In plumbing, it ensures that connections remain secure and free from leaks, contributing to the overall reliability of the system 3.

Sea Water Connection

At sea water connections, the Pipe Plug is used to block off ports that are not in use, preventing the ingress of sea water which could lead to corrosion or contamination of the engine system. This is particularly important in marine environments where salt water can cause significant damage over time 4.

By effectively sealing these various points in the engine system, the Cummins 5289535 Pipe Plug contributes to the maintenance of system pressure, prevention of leaks, and overall operational efficiency.

Conclusion

The Cummins 5289535 Pipe Plug is a vital component in the maintenance and operation of commercial trucks’ fluid systems. Its durable construction, effective sealing capability, and ease of installation make it a reliable choice for preventing leaks and ensuring system integrity. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall efficiency and safety of the truck’s operations.

-

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021

↩ ↩ ↩ -

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ ↩ ↩ -

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ ↩ ↩ -

Automotive Fuels Reference Book, Paul Richards and Jim Barker, SAE International, 2023

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.