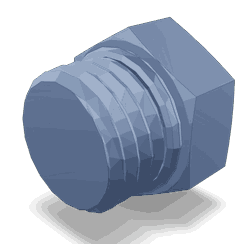

The Cummins 5302985 Pipe Plug is a component designed for use in commercial trucks. Its purpose is to seal openings in fluid systems, ensuring that liquids such as oil, coolant, or other fluids remain contained within the system. This part plays a role in maintaining the integrity and efficiency of the truck’s fluid systems by preventing leaks and contamination 1.

Basic Concepts of Pipe Plugs

A pipe plug is a device used to seal the end of a pipe or a fitting in a fluid system. Its general function is to prevent the escape of fluids, thereby maintaining system pressure and preventing contamination from external elements. Pipe plugs operate by fitting snugly into the opening, creating a barrier that stops fluid flow. They are commonly used in various industries, including automotive and heavy-duty truck manufacturing, to ensure the proper functioning of fluid systems 2.

Purpose of the Cummins 5302985 Pipe Plug

The Cummins 5302985 Pipe Plug is specifically designed to seal openings in the fluid systems of commercial trucks. It is applied in various components where fluid containment is necessary, such as in the engine, transmission, or hydraulic systems. By sealing these openings, the plug helps maintain system pressure, prevent fluid loss, and protect the system from contaminants 3.

Key Features

The Cummins 5302985 Pipe Plug is constructed from materials that offer durability and resistance to corrosion, ensuring long-term performance in demanding environments. Its design includes features that allow for a secure fit within the system, minimizing the risk of leaks. Additionally, the plug may have unique characteristics, such as a tapered or threaded end, to enhance its sealing capabilities 4.

Benefits of Using the Cummins 5302985 Pipe Plug

Utilizing the Cummins 5302985 Pipe Plug offers several advantages. Its durable construction ensures longevity, while its reliable sealing capability maintains system integrity. Efficiency is enhanced as the plug helps prevent fluid loss and contamination, contributing to the overall performance and reliability of the truck’s fluid systems 5.

Installation Process

Installing the Cummins 5302985 Pipe Plug requires following a step-by-step process to ensure a secure fit. This may involve cleaning the opening, applying a sealant if necessary, and using the appropriate tools to insert and tighten the plug. Proper installation is crucial to prevent leaks and ensure the plug functions as intended within the system 6.

Maintenance Tips

Regular maintenance of the Cummins 5302985 Pipe Plug is recommended to ensure its longevity and effectiveness. This includes periodic inspections for signs of wear or damage, cleaning the plug and surrounding area to prevent buildup, and replacing the plug if it shows signs of failure. Adhering to these practices helps maintain the integrity of the truck’s fluid systems 7.

Troubleshooting Common Issues

Common issues associated with pipe plugs, such as leaks or corrosion, can often be addressed through troubleshooting. Identifying the source of a leak may involve inspecting the plug and surrounding area for damage or improper installation. Corrosion can be mitigated through regular maintenance and the use of compatible materials. Addressing these issues promptly helps maintain system efficiency and prevent further damage 8.

Compatibility and Applications

The Cummins 5302985 Pipe Plug is designed for use in specific applications within commercial truck fluid systems. Its compatibility with various components ensures it can be effectively utilized in different systems, contributing to the overall performance and reliability of the truck 9.

Safety Considerations

When handling and installing the Cummins 5302985 Pipe Plug, it is important to observe safety protocols to prevent accidents or injuries. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before installation, and following manufacturer guidelines for installation and maintenance 10.

Environmental Impact

The use and disposal of the Cummins 5302985 Pipe Plug should be considered in terms of environmental impact. Proper disposal practices, including recycling where possible, help minimize waste. Additionally, the design and materials used in the plug may be selected to reduce environmental harm, reflecting a commitment to sustainable practices 11.

About Cummins

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is committed to providing reliable and efficient solutions for the automotive and engine manufacturing industry. The company’s focus on quality and performance is evident in its wide array of components, including the Cummins 5302985 Pipe Plug 12.

Compatibility of Cummins Part 5302985 Pipe Plug

The Cummins part number 5302985 Pipe Plug is designed to fit a variety of Cummins engines, ensuring a secure and reliable seal in the exhaust system. This part is crucial for maintaining the integrity of the exhaust system and preventing leaks, which can affect engine performance and efficiency.

QSB6.7 CM2250

The Pipe Plug 5302985 is compatible with the QSB6.7 CM2250 engine, providing a precise fit for the exhaust system. This engine is known for its robust performance and reliability, making it a popular choice for various applications.

QSK19 CM2350 K105 and QSK19 CM2350 K114

Both the QSK19 CM2350 K105 and QSK19 CM2350 K114 engines are designed for heavy-duty applications and benefit from the use of the Pipe Plug 5302985. This part ensures that the exhaust system remains sealed, which is critical for maintaining optimal engine performance and efficiency.

QSK50 CM2350 K108

The QSK50 CM2350 K108 engine, another high-performance model, is also compatible with the Pipe Plug 5302985. This part is essential for maintaining the exhaust system’s integrity, ensuring that the engine operates at peak efficiency.

QSL9 CM2250 and QSL9 CM2350 L102

The Pipe Plug 5302985 fits seamlessly with both the QSL9 CM2250 and QSL9 CM2350 L102 engines. These engines are designed for a range of applications, and the use of this pipe plug helps maintain the exhaust system’s seal, contributing to the engine’s overall performance.

QST30 CM2350 T101

The QST30 CM2350 T101 engine also benefits from the use of the Pipe Plug 5302985. This part is crucial for ensuring that the exhaust system remains sealed, which is essential for the engine’s performance and efficiency.

By using the Pipe Plug 5302985, owners of these Cummins engines can ensure that their exhaust systems remain sealed and that their engines operate at optimal levels. This part is a critical component in maintaining the reliability and efficiency of these high-performance engines.

Role of Part 5302985 Pipe Plug in Engine Systems

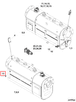

The part 5302985 Pipe Plug is an essential component in various engine systems, particularly within the aftertreatment device and its associated components.

In the aftertreatment device, the Pipe Plug is utilized to seal off specific ports or passages that are not in use during particular operational phases. This ensures that the system operates efficiently by preventing unwanted leaks or emissions.

Within the device itself, the Pipe Plug may be employed to cap off sections of the piping that are not required for the current function, thus maintaining the integrity of the system’s pressure and flow dynamics.

In the context of the aftertreatment system, the Pipe Plug plays a role in managing the flow of exhaust gases. By sealing off certain pathways, it helps in directing the gases through the necessary catalytic converters or filters, enhancing the overall effectiveness of the emissions control process.

The outlet module also benefits from the use of the Pipe Plug. In this module, the Plug ensures that the exhaust gases are correctly routed to the atmosphere or to subsequent treatment stages, preventing any bypass that could compromise emission standards.

Overall, the part 5302985 Pipe Plug is a versatile component that contributes to the efficient and compliant operation of engine systems by ensuring proper sealing and flow management within various aftertreatment components.

Conclusion

The Cummins 5302985 Pipe Plug is a critical component in maintaining the integrity and efficiency of commercial truck fluid systems. Its durable construction, reliable sealing capabilities, and compatibility with various Cummins engines make it an essential part for ensuring optimal engine performance and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of the truck’s fluid systems.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659762, Engine 15N CM2380 M104B.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659762, Engine 15N CM2380 M104B.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659762, Engine 15N CM2380 M104B.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659762, Engine 15N CM2380 M104B.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5659762, Engine 15N CM2380 M104B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.