This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

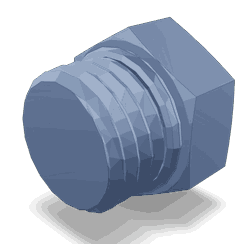

The Cummins 5306840 Pipe Plug is a critical component in commercial truck maintenance and operation, designed to seal openings in fluid systems. This ensures that fluids remain contained, preventing leaks that could lead to system failure or inefficiency. The significance of this part lies in its contribution to the overall reliability and safety of truck operations.

Basic Concepts of Pipe Plugs

A pipe plug is a device used to seal the end of a pipe or a hole in a fluid system. Its primary function is to prevent the escape of fluids, thereby maintaining system integrity and efficiency. Pipe plugs operate by fitting snugly into openings, creating a barrier that stops fluid flow. This is essential in systems where fluid containment is necessary for proper operation 1.

Purpose of the Cummins 5306840 Pipe Plug

This Cummins part serves a specific role in the operation of a truck by sealing openings in various fluid systems such as fuel, coolant, and hydraulic systems. Its application ensures that these systems operate efficiently without fluid loss, which could otherwise lead to decreased performance or system damage 2.

Key Features

The Cummins 5306840 Pipe Plug is characterized by its robust design and material composition, which typically includes metals that offer high resistance to corrosion and wear. These features enhance the plug’s performance and durability, making it suitable for the demanding environments found in commercial truck operations 3.

Benefits

Using this part offers several benefits, including improved system reliability through effective fluid containment, reduced maintenance costs due to its durability, and enhanced safety by preventing leaks that could pose hazards during operation.

Installation Process

Proper installation of the Cummins 5306840 Pipe Plug involves ensuring a secure fit within the designated opening. This process may require specific tools or equipment to achieve the correct tightness without damaging the plug or the surrounding system components. Best practices include verifying the cleanliness of the installation site and the condition of the plug before insertion.

Troubleshooting Common Issues

Common problems with pipe plugs, such as leaks or corrosion, can often be traced back to improper installation or environmental factors. Troubleshooting these issues may involve inspecting the plug for signs of wear or damage, ensuring it is correctly seated, and addressing any corrosion with appropriate treatments or replacements.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of the Cummins 5306840 Pipe Plug. This includes periodic inspections for signs of wear, corrosion, or damage, and replacing the plug if necessary. Adhering to recommended inspection intervals can help prevent unexpected failures and ensure continued system reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck and engine industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its leadership in the power generation and transportation sectors.

Conclusion

The Cummins 5306840 Pipe Plug plays a vital role in ensuring the reliability and safety of commercial truck operations by effectively sealing fluid systems. Its robust design, durability, and ease of maintenance make it a valuable component in the maintenance and operation of commercial trucks. Regular inspection and proper installation are key to maximizing the benefits of this part.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Bosch, Robert GmbH. Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH, 2014.

↩ -

Barton, David C and Fieldhouse, John D. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.