3628605

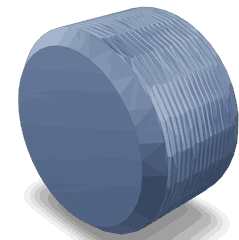

Pipe Plug

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3628605 Pipe Plug is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fluid management system, ensuring the integrity of fluid lines by sealing openings and preventing leaks. This part is integral to maintaining the operational efficiency and safety of the truck.

Basic Concepts of Pipe Plugs

A pipe plug is a device used to seal the end of a pipe or fluid line. Its general function is to prevent the escape of fluids, thereby maintaining system pressure and preventing contamination 1. In the context of a truck’s fluid management system, pipe plugs play a role in ensuring that fluids such as coolant, oil, and fuel remain contained within their respective systems. This containment is vital for the proper operation of the vehicle, as it ensures that fluid levels are maintained and that the system operates under the correct pressure conditions.

Purpose of the Cummins 3628605 Pipe Plug

The Cummins 3628605 Pipe Plug is specifically designed to seal openings in fluid lines within a truck’s system. Its role is to provide a secure barrier that prevents fluid leaks, which could lead to system failure or environmental contamination. By effectively sealing these openings, the pipe plug contributes to the overall efficiency and reliability of the truck’s fluid management system.

Key Features

The Cummins 3628605 Pipe Plug is constructed from materials that offer durability and resistance to corrosion, ensuring long-term performance in demanding environments. Its design includes features that enhance its sealing capabilities, such as a tight fit within the pipe opening and materials that can withstand high pressure and temperature variations. These attributes are crucial for maintaining the integrity of the fluid system in which it is installed 2.

Benefits

Using the Cummins 3628605 Pipe Plug offers several advantages. It contributes to improved system integrity by effectively sealing fluid lines, which helps in maintaining the correct fluid levels and pressure within the system. This, in turn, reduces the need for frequent maintenance, as the risk of leaks is minimized. Additionally, the effective sealing provided by the pipe plug enhances safety by preventing fluid spills that could pose a hazard to the environment or the vehicle’s operation 3.

Installation Process

Installing the Cummins 3628605 Pipe Plug requires careful attention to ensure a secure fit. The process involves cleaning the pipe opening to remove any debris or corrosion, selecting the appropriate size of pipe plug, and inserting it into the opening. Tools such as a hammer may be required to ensure the plug is seated correctly. It is important to follow manufacturer guidelines to ensure the plug is installed correctly and functions as intended.

Troubleshooting Common Issues

Common issues with pipe plugs, such as leaks or corrosion, can often be traced back to improper installation or environmental factors. Troubleshooting these problems involves inspecting the plug for signs of damage or wear, ensuring it is correctly seated, and addressing any corrosion with appropriate treatments. Regular maintenance and inspection can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3628605 Pipe Plug, regular inspection and maintenance are recommended. This includes checking for signs of wear or damage, ensuring the plug remains securely in place, and addressing any corrosion promptly. Replacement guidelines should be followed to maintain the integrity of the fluid system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and efficient components for the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 3628605 Pipe Plug, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Pipe Plug 3628605 Compatibility

The Cummins Pipe Plug part number 3628605 is designed to fit a variety of Cummins engine models. This part is integral to the engine’s exhaust system, ensuring proper sealing and functionality. Here is a detailed breakdown of the engines with which this part is compatible:

6C Series Engines

- 6C8.3

- C8.3 G

ISB Series Engines

- ISB CM550

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150

- ISL9 CM2250

- ISL9.5 CM2880 L138

K Series Engines

- K19

- K38

- K50

KTA Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

L Series Engines

- L8.9 CM2670 L134C

- L9 CM2670 L128B

C Series Engines

- C GAS PLUS CM556

Other Series Engines

- 4B3.9

- 6B5.9

- GTA38 G CMEICS G116C

This part is crucial for maintaining the integrity of the engine’s exhaust system, ensuring that there are no leaks and that the engine operates efficiently. It is essential to verify the compatibility of this part with the specific engine model to ensure proper fitment and functionality.

Role of Part 3628605 Pipe Plug in Engine Systems

The part 3628605 Pipe Plug is instrumental in maintaining the integrity and functionality of various engine systems. It is specifically designed to seal openings in pipes and fittings, preventing leaks and ensuring that fluids and gases remain within the designated pathways.

Accessory Drive and Woodward Housing

In the accessory drive and Woodward housing, the Pipe Plug secures connections and openings, ensuring that no fluid or gas escapes, which is essential for the reliable operation of auxiliary systems driven by the engine.

Base Pan and Oil Pan

Within the base pan and oil pan, the Pipe Plug is used to seal openings where necessary, maintaining the oil level and preventing contamination from external elements.

Block Cylinder Kit and Cylinder Head Mounting

For the block cylinder kit and cylinder head mounting, the Pipe Plug ensures that coolant and lubrication systems remain sealed, which is vital for the thermal management and longevity of the engine components.

Connection and Lubricating Oil Connection

At various connection points and lubricating oil connections, the Pipe Plug plays a role in maintaining the pressure and flow of lubricants, which is essential for reducing friction and wear within the engine.

Auxiliary Cooling Inlet and Heat Exchanger

In the auxiliary cooling inlet and heat exchanger, the Pipe Plug helps to maintain the efficiency of the cooling system by ensuring that coolant flows only through the intended pathways, optimizing heat dissipation.

Cover and Gear Cover Mounting

The cover and gear cover mounting benefit from the Pipe Plug by ensuring that any openings are securely sealed, which is important for maintaining the cleanliness and operational efficiency of the internal components.

Front Gear Housing and Intake Manifold

In the front gear housing and intake manifold, the Pipe Plug ensures that air and other fluids are directed correctly, which is essential for the proper functioning of these components.

Engine Safety Mounting and Exchanger

For engine safety mounting and heat exchanger applications, the Pipe Plug contributes to the safe and efficient operation of these systems by preventing leaks and ensuring proper fluid dynamics.

Expansion Tank and Filter Head Adapter

The expansion tank and filter head adapter rely on the Pipe Plug to maintain system integrity, ensuring that coolant and filtration systems operate without leaks or contamination.

Lubricating Oil Filter Top Level Assembly Head and Manifold

In the lubricating oil filter top level assembly head and manifold, the Pipe Plug ensures that oil filtration and distribution systems remain sealed, which is critical for maintaining oil quality and engine performance.

Water Manifold and Air Intake Manifold

For the water manifold and air intake manifold, the Pipe Plug ensures that water and air are directed efficiently through the engine, which is important for combustion efficiency and engine performance.

Plumbing (Heat Exchanger and Oil Replenishing System)

In the plumbing for the heat exchanger and oil replenishing system, the Pipe Plug ensures that fluids are contained within the system, which is essential for the reliable operation of these subsystems.

Radiator Vent Hose and Seawater Pipe Mount

The radiator vent hose and seawater pipe mount utilize the Pipe Plug to maintain system pressure and prevent leaks, which is important for the efficient operation of the cooling system.

System (Engine Monitoring)

In engine monitoring systems, the Pipe Plug ensures that sensors and fluid pathways remain sealed, which is vital for accurate data collection and system performance.

Water Inlet Tube

Finally, in the water inlet tube, the Pipe Plug ensures that coolant enters the engine as intended, which is essential for maintaining optimal engine temperature and performance.

Conclusion

The Cummins 3628605 Pipe Plug plays a vital role in the fluid management systems of commercial trucks, ensuring the integrity of fluid lines and preventing leaks. Its durable construction, resistance to corrosion, and precise sealing capabilities contribute to the overall efficiency and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this component.

-

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.