This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

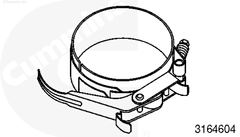

The 3164604 Piston Ring Compressor, a specialized tool from Cummins, is designed for the maintenance and repair of heavy-duty truck engines. It facilitates the installation and removal of piston rings, ensuring engine maintenance procedures are carried out efficiently and effectively.

Basic Concepts of Piston Ring Compressors

A piston ring compressor is essential in engine maintenance for compressing piston rings, allowing for their installation or removal without causing damage. It evenly distributes pressure around the piston rings, securing them in place during maintenance, which is crucial for maintaining their integrity and the engine’s performance 1.

Purpose of the 3164604 Piston Ring Compressor

This Cummins part ensures proper seating and compression of piston rings by applying uniform pressure. Proper seating is vital for engine efficiency, ensuring optimal compression and reducing oil consumption and blow-by 2.

Key Features

The 3164604 is characterized by its robust design and high-quality materials, engineered for durability and reliability in heavy-duty engine maintenance. Its ease of use allows for quick and efficient piston ring installation or removal, and it is compatible with a wide range of engine types.

Benefits of Using the 3164604 Piston Ring Compressor

Using this tool enhances the efficiency of piston ring installation, reducing maintenance time. It ensures piston rings are properly seated, contributing to engine performance and compression. Its longevity and reliability can also lead to reduced maintenance costs over time 3.

Troubleshooting and Maintenance Suggestions

To ensure the longevity and optimal performance of this part, regular inspection for wear or damage is recommended, along with cleaning after each use. Troubleshooting may involve checking for proper alignment and ensuring operation within designed parameters.

Applications and Use Cases

The 3164604 is commonly used in heavy-duty truck applications, including long-haul trucking, construction, and mining operations. Its versatility makes it suitable for various engine types and maintenance scenarios.

Safety Considerations

When using this part, it is important to observe safety practices, including proper handling, safe storage, and following operational safety measures to prevent accidents.

Cummins: A Brief Overview

Cummins Inc. is a global leader in power solutions, including engines and filtration. With over a century of history, Cummins is known for quality, reliability, and innovation. The 3164604 Piston Ring Compressor exemplifies Cummins’ commitment to high-quality tools for the industry.

Role of Part 3164604 Piston Ring Compressor in Engine Systems

The 3164604 is indispensable in engine systems for facilitating the installation and removal of piston rings. It ensures proper seating within piston grooves, which is essential for maintaining engine compression and performance.

Integration with Service Tool Kit

This part is often included in a comprehensive service tool kit for engine maintenance. It works with other tools like piston ring expanders, feeler gauges, and micrometers to ensure accurate and efficient engine maintenance.

Application in Engine Overhaul

During an engine overhaul, this part is used for ring removal, installation, and gap adjustment, ensuring that piston rings are correctly installed and aligned for optimal engine performance.

Ensuring Engine Efficiency

Proper use of the 3164604 within the service toolkit contributes to engine efficiency and longevity by maintaining optimal compression levels, reducing oil consumption, and enhancing overall engine performance.

Conclusion

The 3164604 Piston Ring Compressor is a key component in engine maintenance, playing a significant role in the precise installation and removal of piston rings. Its use ensures engine reliability and efficiency, making it an essential tool in the maintenance and repair of heavy-duty truck engines.

-

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.