This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3880812 Piston Cooling Nozzle is a component designed to enhance the operation of heavy-duty truck engines. Its purpose is to contribute to the thermal management of the engine, ensuring optimal performance and longevity. This Cummins part is significant in the context of heavy-duty trucks, where engine efficiency and reliability are paramount.

Basic Concepts of Piston Cooling Nozzles

Piston cooling nozzles are components within an engine that direct a stream of oil onto the underside of the piston. This process helps in dissipating heat generated during combustion, which is crucial for maintaining engine performance and extending the lifespan of the engine. By managing the temperature of the piston, these nozzles play a role in preventing overheating and potential damage to the engine components 1.

Purpose of the Cummins 3880812 Piston Cooling Nozzle

The Cummins 3880812 Piston Cooling Nozzle is specifically designed to enhance the thermal management within a truck engine. It contributes to maintaining the optimal operating temperature of the piston, which is vital for engine efficiency and reliability. By effectively managing heat, this nozzle helps in preserving the integrity of the engine components, thereby supporting overall engine performance 2.

Key Features

The Cummins 3880812 Piston Cooling Nozzle is characterized by its precise design and the materials used in its construction. It is engineered to deliver a consistent and directed stream of oil to the piston’s underside. The design elements and materials contribute to its durability and effectiveness in high-stress environments typical of heavy-duty truck operations.

Benefits

Utilizing the Cummins 3880812 Piston Cooling Nozzle in a truck engine can lead to improved engine reliability and performance. By effectively managing piston temperature, it helps in reducing the risk of overheating and associated engine damage. Additionally, its role in maintaining engine efficiency can contribute to potential cost savings over time through reduced maintenance needs and enhanced engine lifespan 3.

Installation and Integration

Proper installation of the Cummins 3880812 Piston Cooling Nozzle is crucial for its effective operation within a truck engine. It requires careful alignment and secure fitting to ensure it functions as intended. Considerations for optimal performance include ensuring the nozzle is correctly positioned to deliver oil effectively and that it is compatible with the specific engine model.

Troubleshooting and Maintenance

Common issues with the Cummins 3880812 Piston Cooling Nozzle may include blockages or misalignment, which can affect its performance. Regular maintenance practices, such as cleaning and inspection, are recommended to ensure its continued effectiveness. Addressing issues promptly and performing routine checks can help in maintaining the nozzle’s performance and longevity.

Performance Impact

The Cummins 3880812 Piston Cooling Nozzle impacts engine performance by contributing to efficient thermal management. This can lead to improvements in fuel efficiency, as a well-managed engine temperature allows for more optimal combustion. Additionally, it supports consistent power output and overall engine reliability by preventing overheating and associated damage.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of engine and power generation products. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance engine components. The company’s product offerings cater to various sectors, including heavy-duty trucks, where efficiency and durability are critical.

Piston Cooling Nozzle for Cummins Engines

The Piston Cooling Nozzle, part number 3880812, is a critical component in the cooling system of certain Cummins engines. This nozzle is designed to direct a precise flow of coolant to the piston, ensuring optimal temperature management and enhancing the engine’s performance and longevity.

Application in K19 Engines

The K19 engine series by Cummins is renowned for its robust design and efficiency. The Piston Cooling Nozzle, part number 3880812, is integral to this engine’s cooling system. It is engineered to withstand the high pressures and temperatures typical of the K19 engine, providing reliable cooling to the pistons. This ensures that the engine operates within safe temperature limits, preventing overheating and potential damage.

Grouping with Other Cummins Engines

While the K19 engine is a standout in its own right, the Piston Cooling Nozzle, part number 3880812, is also compatible with other Cummins engines that share similar design principles and cooling requirements. This part’s compatibility extends to various Cummins engine models, ensuring that it can be used across different applications without compromising performance.

Importance of the Piston Cooling Nozzle

The Piston Cooling Nozzle plays a pivotal role in maintaining the efficiency and reliability of Cummins engines. By directing coolant directly to the pistons, it helps in dissipating heat effectively, which is crucial for engines operating under heavy loads or in high-temperature environments. This component’s precision engineering ensures that it fits seamlessly into the engine’s cooling system, providing a reliable and long-lasting solution for temperature management.

Understanding the Integration of Part 3880812 Piston Cooling Nozzle in Engine Systems

The part 3880812 piston cooling nozzle is an essential component in the thermal management system of an engine. It is strategically positioned within the engine block to ensure optimal performance and longevity of the pistons.

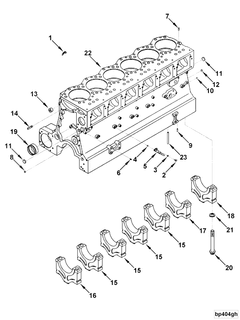

Role in the Engine Block

Within the engine block, the piston cooling nozzle directs a stream of lubricating oil onto the underside of the pistons. This action is vital for dissipating heat away from the piston, which is generated during the combustion process. The consistent cooling provided by the nozzle helps maintain the structural integrity of the piston and prevents thermal expansion that could lead to engine knocking or seizure.

Interaction with the Cylinder Block

The cylinder block houses the pistons and the piston cooling nozzles. The nozzles are typically integrated into the block’s design, ensuring that the oil spray pattern is precise and effective. The cooling nozzles work in concert with the cylinder walls to create a balanced thermal environment within the engine, which is necessary for efficient operation and reduced wear on the cylinder walls.

Integration with the K6 Short Block

In the context of a K6 short block, the piston cooling nozzles are part of a comprehensive cooling strategy that includes other components such as the oil jets and the cooling fins on the pistons themselves. The short block is designed to be a self-contained unit that includes the cylinder block, crankshaft, pistons, and piston cooling nozzles, all engineered to work together seamlessly for enhanced performance and reliability.

Contribution to Base and Performance Parts

The effectiveness of the piston cooling nozzle is a testament to the quality of the base and performance parts it is designed to protect. By ensuring that the pistons remain cool, the nozzle indirectly supports the durability of other performance parts such as the connecting rods, bearings, and the crankshaft. A well-cooled piston contributes to the overall efficiency and power output of the engine, making the cooling nozzle a silent yet significant player in the engine’s performance arsenal.

Conclusion

The Cummins 3880812 Piston Cooling Nozzle is a vital component in the thermal management of heavy-duty truck engines. Its precise design and integration within the engine block contribute to maintaining optimal piston temperature, which is crucial for engine efficiency, reliability, and longevity. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the benefits of this Cummins part.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.