This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Piston Cooling Nozzle 3968877, manufactured by Cummins, is a component designed for heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance engine components. This part is significant in maintaining the efficiency and longevity of truck engines by managing thermal conditions within the piston assembly.

Basic Concepts of Piston Cooling Nozzles

Piston cooling nozzles are components used in internal combustion engines to manage the temperature of the piston. They operate by spraying a fine mist of engine oil onto the underside of the piston, which helps dissipate heat generated during combustion. This cooling mechanism is vital for maintaining optimal engine performance and preventing damage from excessive heat 1.

Purpose of the 3968877 Piston Cooling Nozzle

The 3968877 Piston Cooling Nozzle plays a role in the engine cooling system by directing a stream of oil onto the piston’s underside. This process helps in dissipating heat, which is crucial for maintaining the structural integrity of the piston and ensuring smooth engine operation. By effectively managing thermal conditions, the nozzle contributes to enhanced engine efficiency and longevity 2.

Key Features

The 3968877 Piston Cooling Nozzle is designed with several features that enhance its performance and reliability. These include a precision-machined nozzle tip that ensures an even distribution of oil, a robust construction that withstands high temperatures and pressures, and compatibility with Cummins’ engine systems. These features collectively contribute to the nozzle’s effectiveness in cooling the piston 3.

Benefits

The advantages provided by the 3968877 Piston Cooling Nozzle include improved engine performance through effective heat management, reduced thermal stress on pistons, and enhanced overall engine durability. By maintaining optimal operating temperatures, the nozzle helps in preventing premature wear and potential engine failures 4.

Installation and Integration

Installing the 3968877 Piston Cooling Nozzle involves integrating it into the engine’s oil circulation system. This process requires careful alignment and securing of the nozzle to ensure proper oil flow and effective cooling. Specific requirements may include ensuring the engine is at the correct operating temperature and pressure before installation, and verifying that all connections are secure to prevent oil leaks 5.

Troubleshooting and Maintenance

Common issues with the 3968877 Piston Cooling Nozzle may include clogging of the nozzle tip or leaks in the oil supply line. Diagnostic procedures involve inspecting the nozzle for blockages and checking the oil supply system for integrity. Regular maintenance practices, such as cleaning the nozzle and ensuring the oil system is free of contaminants, are important for ensuring optimal performance 6.

Performance Impact

The 3968877 Piston Cooling Nozzle affects engine performance by contributing to efficient heat management, which can lead to improved fuel efficiency and reduced emissions. By maintaining optimal piston temperatures, the nozzle helps in achieving consistent engine performance under varying load conditions 7.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly for its heavy-duty truck components. The company’s product range includes a variety of engine components designed to meet the demanding requirements of commercial and industrial applications.

Piston Cooling Nozzle Compatibility with Cummins Engines

The Piston Cooling Nozzle, part number 3968877, manufactured by Cummins, is a critical component in several of their engine models. This nozzle plays a vital role in maintaining optimal engine performance by ensuring efficient cooling of the pistons. Here is a detailed description of its compatibility across various Cummins engine models:

B-Series Engines

- B4.5 RGT

- B6.7 G CM

- B6.0 B125

The B-Series engines, including the B4.5 RGT, B6.7 G CM, and B6.0 B125, are designed for a range of applications from agricultural to industrial use. The Piston Cooling Nozzle fits seamlessly into these engines, ensuring that the pistons are adequately cooled, which helps in maintaining engine longevity and performance.

ISB Engines

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

The ISB engines, such as the ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, and ISB6.7 CM2250, are known for their robust performance and reliability. The Piston Cooling Nozzle is designed to fit these engines, providing essential cooling to the pistons and contributing to the overall efficiency and durability of the engine.

ISBE Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series, including the ISBE CM2150, ISBE CM800, and ISBE4 CM850, are engineered for high-performance applications. The Piston Cooling Nozzle is compatible with these engines, ensuring that the pistons are kept at an optimal temperature, which is crucial for maintaining engine efficiency and preventing overheating.

QSB Engines

- QSB4.5 CM850 (CM2850)

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB engines, such as the QSB4.5 CM850 (CM2850), QSB5.9 CM850, QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117, are designed for heavy-duty applications. The Piston Cooling Nozzle is an essential component for these engines, providing the necessary cooling to the pistons to ensure that the engine operates efficiently and reliably under demanding conditions.

ISF Engine

- ISF3.8 CM2220 AN

The ISF3.8 CM2220 AN engine is another model where the Piston Cooling Nozzle is compatible. This engine is designed for applications that require high power and efficiency, and the nozzle ensures that the pistons are adequately cooled, contributing to the engine’s overall performance and longevity.

Role of Part 3968877 Piston Cooling Nozzle in Engine Systems

The part 3968877 Piston Cooling Nozzle is an integral component in the thermal management system of an engine. It is strategically positioned to interact with several key components to ensure optimal engine performance and longevity.

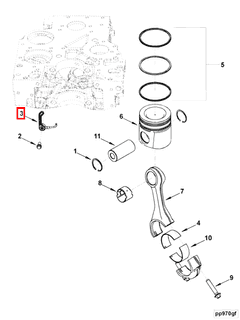

Interaction with the Piston and Connecting Rod

The primary function of the Piston Cooling Nozzle is to direct a jet of lubricating oil onto the underside of the piston. This cooling effect is vital for the piston, which experiences extreme temperatures due to combustion. The connecting rod, which links the piston to the crankshaft, also benefits from this cooling as it helps maintain the structural integrity and operational efficiency of the rod 8.

Relationship with the Cylinder Block and Cylinder Head

Effective cooling of the piston contributes to the overall thermal stability of the cylinder block. By reducing the temperature of the piston, the Piston Cooling Nozzle helps in minimizing thermal expansion, which can lead to increased clearances and potential damage to the cylinder walls. Similarly, the cylinder head, which houses the combustion chamber, operates more efficiently when the underlying components are kept within optimal temperature ranges 9.

Impact on Crankshaft and Bearings

The crankshaft, which converts the linear motion of the pistons into rotational motion, relies on precise clearances between itself and the bearings. Excessive heat can lead to increased wear and reduced lifespan of these components. The cooling effect provided by the Piston Cooling Nozzle helps in maintaining these clearances, thus ensuring smooth operation and durability of the crankshaft and bearings 10.

Contribution to Injector and Injector Plumbing Performance

The injector, responsible for delivering fuel into the combustion chamber, operates under high pressure and temperature conditions. Efficient cooling of the piston indirectly supports the injector’s performance by maintaining a stable environment within the engine. This stability is further enhanced by the injector plumbing, which must withstand varying temperatures and pressures. The cooling effect helps in preserving the integrity of these components 11.

Integration with Overhaul and Gasket Kits

When performing an engine overhaul, the inclusion of a Piston Cooling Nozzle as part of the overhaul kit is beneficial. It ensures that the engine is equipped with modern cooling capabilities from the outset. Similarly, the lower engine gasket kit, which includes seals and gaskets for various engine components, works in conjunction with the cooling nozzle to create a sealed and efficient engine environment 12.

Conclusion

In summary, the 3968877 Piston Cooling Nozzle plays a significant role in the thermal management of an engine. Its interaction with components such as the piston, connecting rod, cylinder block, cylinder head, crankshaft, bearings, injector, and injector plumbing contributes to enhanced engine performance and longevity. By maintaining optimal temperatures, it supports the efficient operation of these components, leading to a more reliable and durable engine system.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 6324545.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 6324545.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 6324545.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.