This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4013070 Piston Skirt, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance engine parts. This Cummins part is significant in the context of heavy-duty truck engines due to its role in ensuring efficient engine operation and durability.

Basic Concepts of Piston Skirts

A piston skirt is the portion of a piston that does not come into contact with the piston rings. It is located on the sides of the piston and plays a role in guiding the piston within the cylinder bore. The piston skirt contributes to the stability and alignment of the piston as it moves up and down within the cylinder, which is crucial for the smooth operation of the engine 1.

Purpose of the 4013070 Piston Skirt

The 4013070 Piston Skirt is designed to enhance the performance and reliability of truck engines. It interacts with the cylinder wall to provide lateral support to the piston, reducing friction and wear. This component helps in maintaining the piston’s alignment and stability, which is vital for the engine’s efficiency and longevity. The skirt’s design allows for optimal thermal expansion and contraction, accommodating the varying temperatures within the engine 2.

Key Features

The 4013070 Piston Skirt features a unique design that includes precision machining and the use of high-quality materials. These elements contribute to its performance and durability. The skirt is crafted to provide a balance between strength and flexibility, ensuring it can withstand the high stresses and temperatures encountered in heavy-duty truck engines. Additionally, the surface finish of the skirt is engineered to minimize friction and wear, enhancing the overall efficiency of the engine.

Benefits

The advantages of the 4013070 Piston Skirt include improved engine efficiency, reduced wear on engine components, and enhanced performance. By providing stable support to the piston, the skirt helps in maintaining consistent engine operation, which can lead to better fuel economy and reduced maintenance costs. The durable construction of the skirt also contributes to the longevity of the engine, making it a valuable component for heavy-duty applications.

Installation Considerations

Proper installation of the 4013070 Piston Skirt is important to ensure optimal performance and longevity. It is recommended to follow the manufacturer’s guidelines for installation, which may include checking for proper clearance between the skirt and the cylinder wall, ensuring the piston is correctly aligned, and verifying that all related components are in good condition. Attention to these details during installation can help prevent issues down the line and ensure the engine operates smoothly.

Troubleshooting Common Issues

Common problems associated with piston skirts can include excessive wear, piston slap, or damage due to improper installation. Potential causes may range from manufacturing defects to operational stresses. Recommended troubleshooting steps involve inspecting the skirt for signs of wear or damage, checking the clearance between the skirt and the cylinder wall, and ensuring that the piston is properly aligned. Addressing these issues promptly can help maintain engine performance and prevent further damage.

Maintenance Tips

Routine maintenance practices can help prolong the life of the 4013070 Piston Skirt and ensure continued engine performance. These practices may include regular inspections for wear or damage, ensuring proper lubrication, and addressing any issues with piston alignment or cylinder wall condition. Keeping the engine clean and well-maintained can also contribute to the longevity of the piston skirt and the overall efficiency of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes engines and components for heavy-duty trucks, among other applications. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry, particularly for heavy-duty truck components.

Cummins Piston Skirt 4013070 Compatibility

The Cummins Piston Skirt part number 4013070 is designed to fit seamlessly within several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, providing a smooth interface between the piston and the cylinder wall.

Compatible Engines

- QSV81G, QSV91-G4 CM558/CM700 V102, QSV91G

These engines benefit from the precision engineering of the Cummins Piston Skirt 4013070. The part’s design ensures it fits snugly within the specified engine models, maintaining the necessary clearance and reducing friction for efficient engine operation.

Grouping of Engines

The engines listed above, QSV81G, QSV91-G4 CM558/CM700 V102, and QSV91G, share common design principles and performance characteristics. The compatibility of the Cummins Piston Skirt 4013070 across these models underscores its versatility and reliability in various engine configurations.

Understanding the Integration of Part 4013070 Piston Skirt in Engine Systems

The part 4013070 Piston Skirt is an essential component in the assembly and functionality of various engine systems. Its role is to ensure smooth operation and efficiency within the engine’s internal mechanisms.

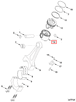

Interaction with the Engine Piston and Piston and Liner Assembly

The Piston Skirt, identified by part number 4013070, interfaces directly with the engine piston. This interaction is vital for the piston’s lateral stability within the cylinder bore. The skirt’s design allows for minimal friction as the piston moves up and down, which is crucial for the engine’s performance. In the piston and liner assembly, the skirt contributes to the piston’s alignment and movement, ensuring that the piston rings seal effectively against the cylinder walls.

Contribution to the Connecting Rod and Piston Mechanism

In conjunction with the connecting rod, the Piston Skirt plays a role in translating the piston’s linear motion into rotational force for the crankshaft. The skirt’s design must accommodate the forces exerted by the connecting rod, ensuring that the piston remains centered and operates smoothly within the cylinder.

Role in the Cylinder Head and Camshaft System

Although the Piston Skirt does not directly interact with the cylinder head or camshaft, its proper function is indirectly related to the performance of these components. A well-functioning piston skirt contributes to the engine’s overall efficiency, which in turn affects the timing and operation of the camshaft and the combustion process managed by the cylinder head.

Importance in Engine Piston Kit

When considering an engine piston kit, the Piston Skirt is a component that should not be overlooked. It is part of the assembly that ensures the piston’s durability and performance. The skirt’s condition and fit are indicative of the piston’s ability to withstand the stresses of engine operation and contribute to the kit’s overall performance capabilities.

Overall Engine Performance

The integration of the Piston Skirt into the engine system is a testament to the intricate balance required for optimal engine performance. Its role in facilitating the piston’s movement, ensuring proper alignment, and contributing to the engine’s efficiency underscores the importance of each component within the engine’s complex network.

Conclusion

The 4013070 Piston Skirt by Cummins is a critical component in the operation of heavy-duty truck engines. Its design and features contribute to the engine’s efficiency, durability, and overall performance. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and reliability of this part in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.