4324122

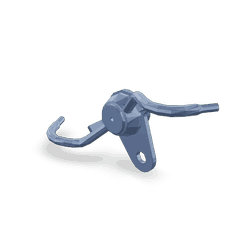

Piston Cooling Nozzle

Cummins®

IN STOCK

4 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4324122 Piston Cooling Nozzle is a component designed to enhance the thermal management of heavy-duty truck engines. Its purpose is to direct a stream of oil onto the underside of the piston, aiding in the dissipation of heat generated during combustion. This part is significant in maintaining the operational integrity and efficiency of truck engines, particularly under demanding conditions 1.

Basic Concepts of Piston Cooling Nozzles

Piston cooling nozzles are integral to the engine’s cooling system. They function by spraying oil directly onto the piston’s underside, which absorbs heat and then circulates back to the oil pan to be cooled. This process is vital for maintaining optimal engine temperature, preventing overheating, and ensuring consistent performance and longevity of the engine components 2.

Purpose of the Cummins 4324122 Piston Cooling Nozzle

This Cummins part plays a role in the engine’s thermal management system by directing a precise stream of oil to cool the piston. This cooling effect helps in managing the thermal loads on the piston, which is crucial for maintaining engine efficiency and reliability, especially during high-stress operations.

Key Features

The Piston Cooling Nozzle is characterized by its robust design and the use of high-quality materials that ensure durability and efficient performance. Its design allows for an optimal spray pattern that maximizes cooling efficiency. Additionally, the nozzle is engineered to withstand the high pressures and temperatures within the engine environment.

Benefits

The advantages of this part include enhanced engine reliability through effective thermal management, improved performance under high-stress conditions, and potential increases in fuel efficiency due to reduced thermal loads on engine components. These benefits contribute to the overall longevity and operational efficiency of the engine.

Installation and Integration

Installation of the Piston Cooling Nozzle involves precise fitting within the engine system to ensure proper oil flow and cooling effectiveness. It requires adherence to specific guidelines to maintain the integrity of the cooling system and to ensure compatibility with the engine’s design.

Troubleshooting and Maintenance

Common issues with the Piston Cooling Nozzle may include clogging or misalignment, which can affect cooling efficiency. Regular inspection and cleaning are recommended to prevent such issues. Additionally, ensuring the nozzle is correctly installed and aligned can help maintain optimal performance and longevity.

Performance Impact

The Piston Cooling Nozzle contributes to engine performance by aiding in temperature regulation, which can lead to more consistent power output and improved overall engine health. Effective cooling helps in reducing thermal stress on engine components, thereby enhancing durability and operational efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins is renowned for its commitment to quality and performance in the automotive and heavy-duty truck industry 3.

Role of Part 4324122 Piston Cooling Nozzle in Engine Systems

This part is an integral component in the thermal management system of an engine. It is strategically positioned to interact with both the engine block and the cylinder, ensuring optimal performance and longevity of these components.

Interaction with the Engine Block

The engine block houses the cylinders and pistons, and it is the foundational structure of the engine. The Piston Cooling Nozzle is mounted within the block, typically near the lower portion where the piston travels. Its primary function is to direct a jet of lubricating oil onto the underside of the piston. This oil jet helps in dissipating heat away from the piston, preventing overheating and potential damage to the engine block. The consistent cooling provided by the nozzle ensures that the block maintains structural integrity and operational efficiency over time.

Interaction with the Cylinder

The cylinder is where the piston moves up and down, driven by the combustion process. The Piston Cooling Nozzle plays a significant role in maintaining the cylinder’s condition by ensuring that the piston remains cool. When the piston is adequately cooled, it expands less, which helps in maintaining a proper fit within the cylinder. This reduces the risk of piston seizure and scoring on the cylinder walls. Additionally, the controlled temperature of the piston contributes to more efficient combustion and better overall engine performance.

Conclusion

In summary, the 4324122 Piston Cooling Nozzle works in concert with the engine block and cylinder to enhance the engine’s thermal management, ensuring both components operate within their optimal temperature ranges. This contributes to the overall efficiency, reliability, and longevity of the engine.

-

Thorsten Boger, Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩ -

Wolf-Henning Schneider, Pistons and Engine Testing, Springer Nature, 2016.

↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3034408 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.