2890938

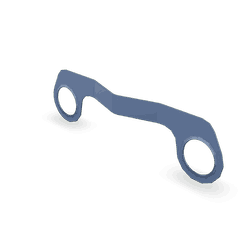

Lockplate

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 2890938 Belt Tensioner is a component designed to maintain the proper tension on drive belts within commercial truck engines. Its role is significant in ensuring the efficient operation of various engine-driven accessories, such as alternators, water pumps, and air conditioning compressors.

Basic Concepts of Belt Tensioners

A belt tensioner is a device used in an engine system to keep drive belts at the correct tension. This is achieved through a spring-loaded mechanism that applies consistent pressure to the belt, compensating for wear and thermal expansion. Maintaining proper belt tension is important for the efficient transfer of power from the engine to its accessories, reducing the risk of belt slippage, noise, and premature wear 1.

Purpose of the Cummins 2890938 Belt Tensioner

This Cummins part plays a role in the operation of a truck by ensuring that drive belts remain under the correct amount of tension. This function is vital for the reliable operation of engine-driven accessories, contributing to overall engine performance and longevity. By maintaining optimal belt tension, the tensioner helps prevent issues such as belt slippage, which can lead to inefficient accessory operation and increased wear on both the belt and the tensioner itself.

Key Features

The 2890938 is characterized by its robust design, which includes high-quality materials that enhance durability and performance. Key features include a precision-machined pulley, a durable spring mechanism for consistent tension application, and a housing designed to withstand the harsh environments typical of commercial truck operations. These design elements contribute to the tensioner’s reliability and efficiency in maintaining belt tension.

Benefits of Using the Cummins 2890938 Belt Tensioner

Utilizing this part offers several advantages. These include improved belt life due to consistent tension, enhanced engine performance through reliable accessory operation, and reduced maintenance requirements thanks to its durable construction. The tensioner’s design also contributes to quieter engine operation by minimizing belt noise associated with improper tension 2.

Installation Process

Installing the 2890938 involves several steps. First, the old tensioner should be removed, taking care to note its position and any adjustments made. The new tensioner is then positioned in place, ensuring it aligns correctly with the belt and other components. Tools required may include a socket wrench for securing the tensioner in place and a belt tension gauge to ensure the correct tension is applied. It’s important to follow the manufacturer’s instructions closely to ensure proper installation.

Troubleshooting Common Issues

Common problems associated with belt tensioners include noise, slippage, and premature wear. Noise can often be traced to improper belt tension or a worn tensioner, while slippage may indicate a belt that is either too loose or glazed. Premature wear on the tensioner or belt could suggest an underlying issue with the engine’s accessory drive system. Troubleshooting steps may involve adjusting the tension, inspecting the belt for damage, or replacing worn components.

Maintenance Tips

To ensure the longevity and optimal performance of the 2890938, regular maintenance practices are recommended. These include periodic inspection of the belt for signs of wear or glazing, ensuring the tensioner operates smoothly without excessive noise, and checking that the belt tension remains within the manufacturer’s specified range. Addressing any issues promptly can help prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 2890938, designed to meet the demanding requirements of commercial truck applications.

Belt Tensioner Part 2890938 Compatibility with Cummins Engines

The Belt Tensioner part number 2890938, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for maintaining the proper tension of the engine’s serpentine belt, ensuring efficient operation and longevity of the engine components.

QSK19 and CM2350 Engines

The QSK19 and CM2350 engines are part of Cummins’ QSK series, which are known for their robust design and high performance. The Belt Tensioner part 2890938 fits seamlessly with these engines, providing the necessary tension to keep the serpentine belt in optimal condition. This ensures that the alternator, water pump, and other accessories driven by the belt operate efficiently, reducing wear and tear on the engine components.

K105 Engine

The K105 engine, another member of the Cummins lineup, also benefits from the use of the Belt Tensioner part 2890938. This part is engineered to fit the specific design and requirements of the K105 engine, ensuring that the belt remains properly tensioned. This is critical for maintaining the balance between the engine’s power output and the efficiency of the ancillary systems it drives.

Grouping of Engines

While the QSK19 and CM2350 engines are part of the same series and share many common components, the K105 engine represents a different segment within Cummins’ engine portfolio. Despite these differences, the Belt Tensioner part 2890938 is designed to be versatile enough to fit these various engines, providing a reliable solution for maintaining belt tension across different engine models.

Role of Part 2890938 Belt Tensioner in Engine Systems

The part 2890938 Belt Tensioner is an integral component in maintaining the optimal performance of various engine systems. Its primary function is to ensure that the serpentine belt, which drives multiple engine accessories, remains under the correct amount of tension. This is essential for the efficient operation of components such as the alternator, water pump, power steering pump, and air conditioning compressor.

In an engine arrangement that includes a turbocharger, the Belt Tensioner plays a significant role. The turbocharger relies on the serpentine belt to drive its compressor, which in turn forces more air into the engine, enhancing performance. Proper tension on the belt ensures that the turbocharger operates smoothly without slippage, which could lead to inefficient air delivery and reduced engine performance.

When considering the single head gasket kit and upper engine gasket kit, the Belt Tensioner indirectly supports these components by maintaining the integrity of the engine’s accessory drive system. A well-tensioned belt reduces the risk of belt failure, which could cause the engine to overheat if the water pump were to stop functioning or lead to a loss of power steering assist. This, in turn, helps protect the head gasket and other engine seals from undue stress that might arise from component failure.

Conclusion

In summary, the part 2890938 Belt Tensioner is a key element in the harmonious operation of the engine’s accessory drive system, supporting critical components and ensuring that the engine runs efficiently and reliably. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of engine performance and maintenance make it a valuable component in commercial truck applications 3.

-

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ -

Michael Hilgers, Transmissions and Drivetrain Design, Springer Vieweg, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.