This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

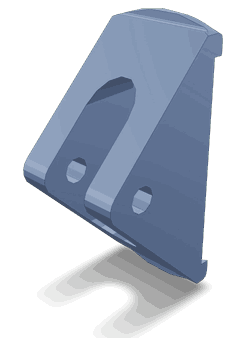

The Cummins 3162881 Liner Remover Plate is a specialized component designed for the maintenance and repair of heavy-duty truck engines. Its primary role is to facilitate the removal and installation of cylinder liners, which are essential components in the engine’s operation. This part is significant in ensuring that engine maintenance procedures are carried out efficiently and with minimal risk to the engine’s components.

Purpose and Function

The Liner Remover Plate plays a role in the engine maintenance process by providing a stable and secure platform for the removal and installation of cylinder liners. It is designed to evenly distribute the forces applied during these procedures, which helps to prevent damage to the cylinder block and other surrounding components. By using this plate, technicians can perform liner changes more effectively, ensuring that the engine continues to operate at optimal performance levels 1.

Design and Construction

The Cummins 3162881 Liner Remover Plate is constructed from high-quality materials that offer durability and reliability. Its design includes features that enhance its functionality, such as a precise fit to the cylinder block and robust construction to withstand the forces involved in liner removal and installation. The materials used are chosen for their strength and resistance to wear, ensuring that the plate can endure repeated use in demanding engine maintenance environments 2.

Installation Process

Installing the Liner Remover Plate involves several steps to ensure it is properly positioned and secured. Technicians should begin by preparing the engine, ensuring that it is clean and free from any debris that could interfere with the installation. The plate is then aligned with the cylinder block, and any necessary bolts or fasteners are tightened to secure it in place. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the plate is properly installed.

Benefits of Using the Liner Remover Plate

Using the Cummins 3162881 Liner Remover Plate offers several advantages. It improves the efficiency of liner removal and installation processes, reducing the time required for these tasks. Additionally, it minimizes the risk of damage to engine components during maintenance, which can lead to costly repairs and downtime. The plate also contributes to enhanced overall engine performance by ensuring that cylinder liners are installed correctly and securely 3.

Common Issues and Troubleshooting

While the Liner Remover Plate is designed for reliability, there may be instances where issues arise. Common problems can include improper fitment, damage to the plate, or difficulties in securing it to the cylinder block. Troubleshooting these issues involves inspecting the plate for any signs of wear or damage, ensuring it is correctly aligned with the cylinder block, and verifying that all fasteners are properly tightened. In cases where the plate is damaged, replacement may be necessary to ensure the integrity of the engine maintenance process.

Maintenance and Care

To ensure the longevity and optimal performance of the Liner Remover Plate, regular maintenance and care are required. This includes cleaning the plate after each use to remove any debris or contaminants that could affect its functionality. Inspections should be conducted to check for signs of wear or damage, and any necessary repairs or replacements should be carried out promptly. Following these guidelines will help maintain the plate’s effectiveness and reliability over time.

Safety Considerations

When working with the Liner Remover Plate, it is important to follow safety precautions to protect both the technician and the engine. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to prevent injury. Proper handling and storage of the plate are also crucial to maintain its condition and prevent accidents. Additionally, technicians should be aware of the correct disposal practices for any waste materials generated during the maintenance process.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories worldwide. The company’s product offerings are designed to meet the demanding requirements of various industries, including transportation, construction, and power generation. Cummins’ dedication to advancing technology and improving efficiency is evident in its comprehensive range of components and systems, including the Cummins 3162881 Liner Remover Plate.

Conclusion

The Cummins 3162881 Liner Remover Plate is a vital component in the maintenance and repair of heavy-duty truck engines. Its design and construction ensure durability and reliability, while its use improves the efficiency and safety of engine maintenance procedures. Regular maintenance and adherence to safety guidelines are essential to ensure the longevity and optimal performance of this part.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.