This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

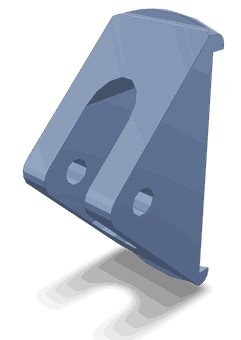

The 3162882 Liner Remover Plate is a specialized component designed for the maintenance and repair of heavy-duty truck engines. This Cummins part is integral to the process of removing and installing cylinder liners, which are essential components in the engine’s operation. Its role in facilitating these tasks ensures that maintenance procedures are carried out efficiently and effectively, contributing to the overall reliability and performance of the engine.

Purpose and Function

The Liner Remover Plate plays a role in the operation and maintenance of truck engines by providing a stable platform for the removal and installation of cylinder liners. It is designed to align with the engine block, ensuring that the liner can be extracted or inserted with precision. This part simplifies what would otherwise be a complex and time-consuming process, allowing for more efficient maintenance operations 1.

Key Features

The 3162882 is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. It is engineered to withstand the stresses associated with liner removal and installation, ensuring that it remains functional over multiple uses. The plate’s design includes features that enhance its stability and alignment with the engine block, further contributing to its effectiveness in maintenance procedures 2.

Benefits

Utilizing the 3162882 Liner Remover Plate offers several advantages. It improves the efficiency of liner removal processes, reducing the time required for maintenance operations. This can lead to decreased downtime for heavy-duty trucks, enhancing their availability for operation. Additionally, by facilitating precise liner installation, the plate contributes to the enhancement of engine performance post-maintenance, ensuring that the engine operates at optimal levels 3.

Installation and Usage

Proper installation and usage of the Liner Remover Plate involve several steps to ensure effective and safe operation. It is important to align the plate correctly with the engine block before securing it in place. Once installed, the plate should be used in conjunction with the appropriate tools for liner removal or installation. Adhering to best practices and safety precautions, such as wearing protective gear and ensuring the engine is cool before beginning work, is crucial for safe operation 4.

Troubleshooting and Maintenance

Common issues with the Liner Remover Plate may include misalignment or damage to the plate itself. Troubleshooting steps involve checking the alignment of the plate with the engine block and inspecting the plate for any signs of wear or damage. Regular maintenance, such as cleaning the plate after use and inspecting it for any necessary repairs, can prolong its lifespan and ensure optimal performance.

Compatibility and Application

The 3162882 Liner Remover Plate is designed for use with specific types of engines and truck models. Its applicability extends to various maintenance scenarios, making it a versatile tool for professionals working on heavy-duty trucks. Understanding the compatibility of this part with specific engine types is important for ensuring its effective use in maintenance procedures.

Cummins: A Brief Overview

Cummins Inc. is a leader in the manufacturing of diesel engines, with a history of innovation and commitment to quality in the automotive industry. The company’s expertise in engine technology and its dedication to producing reliable and efficient components are evident in products like the 3162882 Liner Remover Plate. Cummins’ commitment to advancing diesel engine technology ensures that its parts contribute to the performance and reliability of heavy-duty trucks.

Conclusion

The 3162882 Liner Remover Plate by Cummins is a critical component for the maintenance and repair of heavy-duty truck engines. Its design, functionality, and the benefits it offers make it an invaluable tool for professionals in the field. Proper installation, usage, and maintenance of this part ensure its longevity and effectiveness in enhancing engine performance and reliability.

-

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Garrett, TK, K Newton, and W Steeds. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Cummins Inc. Service Manual (5579755) for D4.5 CM2620 D104B engine.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.