This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

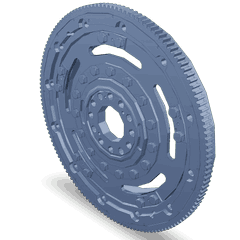

The Cummins 3629372 Flexplate is a component designed for use in commercial trucks. It serves a pivotal role in the drivetrain by connecting the engine to the transmission through the torque converter. This connection facilitates the transfer of power from the engine to the transmission, enabling the vehicle to move 1.

Basic Concepts of a Flexplate

A flexplate is a component in automatic transmission systems. It functions similarly to a flywheel in manual transmissions but is typically made from a different material and designed to accommodate the torque converter. The flexplate is bolted to the engine’s crankshaft and interacts with the torque converter to transmit engine power to the transmission. Unlike a flywheel, which is solid and heavier, a flexplate is usually made from a lighter, flexible material, often steel, to reduce weight and accommodate the torque converter’s needs 2.

Purpose of the Cummins 3629372 Flexplate

This Cummins part plays a role in the operation of a truck by providing a connection between the engine and the transmission. It works in conjunction with the torque converter to ensure smooth power transmission. When the engine produces power, the flexplate transmits this power through the torque converter to the transmission, which then distributes it to the wheels. This component is engineered to handle the high torque and stress associated with commercial truck operations 3.

Key Features

The Cummins 3629372 Flexplate is characterized by its robust design and high-quality materials. It is constructed from durable steel, ensuring it can withstand the rigors of heavy-duty use. The flexplate features a precise bolt pattern that ensures a secure fit to the engine’s crankshaft. Additionally, it is designed with flexibility in mind, allowing it to accommodate the movements and stresses inherent in the drivetrain system. These features contribute to its performance and longevity in demanding applications 4.

Benefits

This part offers several benefits, including improved efficiency and durability. Its design allows for efficient power transfer from the engine to the transmission, enhancing the overall performance of the truck. The use of high-quality materials ensures that the flexplate can withstand the high torque and stress levels typical in commercial truck applications. Furthermore, its compatibility with specific truck models ensures optimal fit and function, contributing to the reliability and efficiency of the vehicle.

Installation Considerations

Proper installation of the Cummins 3629372 Flexplate is important to ensure it functions correctly and efficiently. It is recommended to follow the manufacturer’s guidelines for installation, which may include specific torque settings for the bolts securing the flexplate to the crankshaft. Using the correct tools and procedures during installation helps prevent damage to the flexplate and ensures a secure connection between the engine and transmission.

Troubleshooting Common Issues

Common issues with the Cummins 3629372 Flexplate may include cracks, excessive wear, or failure to engage properly with the torque converter. If such issues arise, it is important to inspect the flexplate for signs of damage or wear. Solutions may involve repairing or replacing the flexplate, ensuring that all connections are secure, and verifying that the torque converter is functioning correctly. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the Cummins 3629372 Flexplate operates efficiently and has a long service life, regular maintenance is recommended. This includes inspecting the flexplate for signs of wear or damage during routine engine maintenance. Ensuring that all bolts are tightened to the manufacturer’s specifications and that the torque converter is in good condition can help prevent issues. Additionally, keeping the drivetrain clean and free of debris can contribute to the overall performance and longevity of the flexplate.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice among commercial truck manufacturers and operators.

Flexplate 3629372 Compatibility with Cummins Engines

The Flexplate 3629372, manufactured by Cummins, is designed to interface seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This flexplate is engineered to fit specific engine models, providing a robust connection between the engine and the transmission.

K38 Engines

For the K38 engines, the Flexplate 3629372 is meticulously crafted to match the unique specifications of this engine series. Its design ensures a precise fit, facilitating smooth power transfer and minimizing the risk of mechanical failures.

QSK38 and CM2150 Engines

The Flexplate 3629372 is also compatible with the QSK38 and CM2150 engines. These engines benefit from the flexplate’s precision engineering, which supports efficient torque transmission and enhances overall engine performance. The flexplate’s robust construction is tailored to withstand the operational demands of these high-performance engines.

MCRS Engines

In the case of the MCRS engines, the Flexplate 3629372 is engineered to align perfectly with the engine’s specifications. This ensures that the flexplate can effectively manage the power flow from the engine to the transmission, contributing to the engine’s reliability and longevity.

Each of these engines relies on the flexplate to maintain a stable and efficient connection, ensuring that the power generated by the engine is effectively transferred to the transmission. The Flexplate 3629372’s compatibility with these Cummins engines underscores its importance in maintaining the integrity and performance of the engine-transmission system.

Role of Part 3629372 Flexplate in Engine Systems

This part is an integral component in the operation of engine systems, particularly in its interaction with the flywheel.

When the engine is running, the flexplate is driven by the crankshaft, transferring rotational force to the flywheel. This transfer of force is essential for the operation of the starter motor during engine start-up. As the starter motor engages, it spins the flexplate, which in turn rotates the crankshaft via the flywheel. This initial rotation is necessary to start the combustion process.

During normal engine operation, the flexplate continues to play a role in maintaining the smooth transfer of power from the engine to the transmission. It absorbs vibrations and torsional stresses that occur as a result of the engine’s operation, ensuring that these stresses do not adversely affect other components in the drivetrain.

The flexplate also contributes to the efficiency of the engine by providing a lightweight alternative to traditional solid metal flywheels. Its design allows for reduced rotational mass, which can lead to quicker acceleration and improved fuel efficiency.

Conclusion

In summary, the Cummins 3629372 Flexplate is a key component in the engine system, facilitating the start-up process, managing power transfer, and contributing to the overall efficiency and smoothness of engine operation.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.