This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

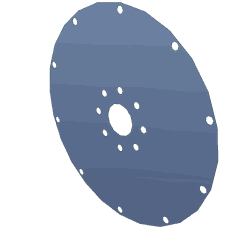

The Cummins 3919590 Flexplate is a component designed for use in heavy-duty trucks. It serves as a link in the drivetrain, facilitating the transfer of power from the engine to the transmission. This flexplate is engineered to withstand the demanding conditions encountered in heavy-duty applications, ensuring reliable performance and durability.

Basic Concepts of Flexplates

A flexplate is a type of coupling device used in automatic transmissions. It functions similarly to a flywheel in manual transmissions but is typically made from a different material and designed to accommodate the torque converter. Unlike a flywheel, which is solid and made of metal, a flexplate is usually made of stamped steel and has a series of holes or slots to allow for the attachment of the starter motor. It plays a role in the drivetrain by providing a flexible connection between the engine and transmission, allowing for smoother operation and accommodating the varying loads and stresses encountered in heavy-duty applications 1.

Purpose of the Cummins 3919590 Flexplate

The Cummins 3919590 Flexplate is designed to play a role in the operation of heavy-duty trucks by connecting the engine to the torque converter. This connection allows for the efficient transfer of power from the engine to the transmission, enabling the truck to move. The flexplate works in conjunction with the torque converter to manage the transmission of power, ensuring smooth and reliable operation under various driving conditions.

Key Features

The Cummins 3919590 Flexplate is characterized by several key features that enhance its performance and durability. It is constructed from high-strength materials, ensuring it can withstand the high torque and stress levels encountered in heavy-duty applications. The design includes precise machining and balancing to reduce vibrations and ensure smooth operation. Additionally, the flexplate features a robust attachment system for the starter motor, facilitating easy installation and reliable starting performance.

Benefits

The Cummins 3919590 Flexplate offers several benefits that contribute to its popularity in heavy-duty truck applications. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The precise engineering and balancing of the flexplate help to minimize vibrations, leading to a smoother driving experience. Additionally, the robust design and reliable performance of the flexplate can result in potential cost savings over time by reducing maintenance and replacement costs 2.

Installation Considerations

Proper installation of the Cummins 3919590 Flexplate is important to ensure optimal performance and longevity. It is recommended to follow Cummins’ guidelines for installation, which may include specific torque settings for attaching the flexplate to the engine and transmission. Ensuring that the flexplate is properly aligned and balanced during installation can help to prevent vibrations and ensure smooth operation. Additionally, it is important to inspect the flexplate for any damage or defects before installation to avoid potential issues down the line.

Troubleshooting Common Issues

Common issues associated with flexplates include cracking or failure due to excessive stress or wear. If a flexplate is suspected to be faulty, it is important to perform a thorough inspection to identify the source of the problem. This may involve checking for signs of wear, cracks, or damage to the flexplate, as well as inspecting the torque converter and transmission for any issues that may be contributing to the problem. Addressing these issues promptly can help to prevent further damage and ensure the continued reliable operation of the drivetrain.

Maintenance Tips

Regular maintenance of the Cummins 3919590 Flexplate is important to ensure optimal performance and longevity. This may include periodic inspections for signs of wear, damage, or corrosion, as well as ensuring that the flexplate is properly lubricated and free from debris. Following Cummins’ recommended maintenance schedule and guidelines can help to identify and address potential issues before they become more serious, ensuring the continued reliable operation of the drivetrain.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence and customer satisfaction has made it a trusted name in the industry, providing solutions that meet the demanding needs of heavy-duty applications 3.

Flexplate 3919590 Compatibility with Cummins Engines

The Flexplate part number 3919590, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for the proper functioning of the engine’s torque transfer from the engine to the transmission. Here is a detailed look at the compatibility of this flexplate with various Cummins engines:

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- ISL CM2150

- ISL CM554

- ISL G CM2180

The ISB series engines are known for their reliability and efficiency, and the Flexplate 3919590 is engineered to ensure smooth operation and durability when paired with these engines.

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

The ISC series engines are designed for heavy-duty applications, and the Flexplate 3919590 is compatible with these engines, ensuring robust performance and longevity.

ISF Series Engines

- ISF4.5 CM2220 F123

The ISF series engines are typically used in applications requiring high power output, and the Flexplate 3919590 is specifically designed to fit these engines, ensuring optimal torque transfer.

Other Cummins Engines

- 6B5.9

- 6C8.3

- B6.7 CM2350 B135B

- B6.7 G CMOH6.0 B125

- C GAS PLUS CM556

- C8.3 G

- F4.5 CM2620 F139B

These engines, while less common, are still supported by the Flexplate 3919590. Cummins ensures that this flexplate is compatible with a wide range of their engine models, providing flexibility and reliability across various applications.

Role of Part 3919590 Flexplate in Engine Systems

The part 3919590 Flexplate is a component in the operation of automatic transmission systems, working in conjunction with several other engine components to ensure smooth and efficient power transfer.

Interaction with the Torque Converter

In automatic transmission vehicles, the flexplate takes the place of the traditional flywheel found in manual transmission systems. It is bolted to the rear of the engine crankshaft. The flexplate interfaces directly with the torque converter, which is part of the automatic transmission. As the engine runs, the crankshaft’s rotation is transferred to the flexplate. The flexplate then transmits this rotational force to the torque converter, which uses hydraulic fluid to multiply torque and transfer power to the transmission input shaft. This process allows for the seamless transfer of power from the engine to the transmission, enabling the vehicle to move.

Dampening Vibrations

One of the key functions of the flexplate is to dampen vibrations produced by the engine. Unlike a solid flywheel, the flexplate is designed with flexibility, typically incorporating a series of dampers or springs. These dampers absorb and reduce the vibrations generated during engine operation, providing a smoother ride and reducing wear on connected components.

Starter Motor Engagement

During the starting process, the flexplate plays a vital role in engaging the starter motor. The starter motor’s gear, known as the starter bendix, meshes with the teeth on the flexplate. When the starter motor is activated, it spins the flexplate, which in turn rotates the crankshaft, initiating engine combustion.

Integration with the Engine Mounts

The flexplate’s role extends to the engine’s mounting system. By helping to manage and distribute engine vibrations, the flexplate assists in maintaining the integrity and longevity of the engine mounts. This ensures that the engine remains securely positioned within the vehicle’s frame, contributing to overall vehicle stability and performance.

Coordination with the Transmission

In automatic transmission systems, the flexplate must work in harmony with various transmission components, including the valve body, planetary gear sets, and the torque converter clutch. Proper functioning of the flexplate ensures that power is consistently and efficiently transmitted through these components, allowing for smooth gear changes and optimal vehicle performance.

Conclusion

The Cummins 3919590 Flexplate is a multifaceted component that plays a significant role in the operation of automatic transmission engine systems. Its ability to transmit power, dampen vibrations, engage the starter motor, support engine mounts, and coordinate with transmission components makes it an indispensable part of the engine’s functionality.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.