3163105

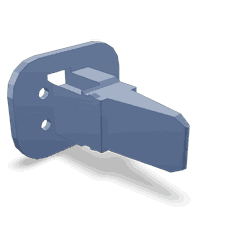

Lock-wedge,deutsch Plug

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lock-Wedge, Deutsch Plug (Part #3163105) manufactured by Cummins is a specialized component designed for use in commercial trucks. This part is integral to maintaining the integrity of electrical systems within these vehicles. Its application ensures that electrical connections remain secure and reliable, which is vital for the overall performance and safety of the truck 1.

Basic Concepts

The Lock-Wedge, Deutsch Plug operates on fundamental principles that ensure secure and stable electrical connections. Its design incorporates a lock-wedge mechanism that firmly holds the plug in place once inserted into a Deutsch connector. This mechanism is crucial for preventing accidental disconnections and ensuring a consistent electrical pathway. The plug is engineered to integrate seamlessly with Deutsch connector systems, which are widely used in the commercial truck industry for their durability and reliability 2.

Purpose and Function

The primary role of the Lock-Wedge, Deutsch Plug is to secure electrical connections within a truck’s system. By providing a stable and reliable connection, it ensures that electrical signals and power are transmitted efficiently. This function is particularly important in commercial trucks, where consistent electrical performance is necessary for various systems, including lighting, instrumentation, and engine controls 3.

Key Features

Several key features contribute to the effectiveness of the Lock-Wedge, Deutsch Plug. Its robust construction ensures durability under the demanding conditions typical of commercial truck operations. The plug is designed for ease of installation, allowing technicians to quickly and securely connect it to the appropriate Deutsch connectors. Additionally, its compatibility with Deutsch connector systems ensures that it can be used across a wide range of truck models and applications 4.

Benefits

The Lock-Wedge, Deutsch Plug offers several advantages. Improved electrical connection stability reduces the risk of intermittent connections, which can lead to system malfunctions. The plug’s design also minimizes maintenance requirements, as its secure fit reduces the need for frequent checks and adjustments. Furthermore, the enhanced reliability of the electrical system contributes to the overall performance and safety of the truck 5.

Installation Process

Proper installation of the Lock-Wedge, Deutsch Plug involves several steps to ensure a secure and effective connection. Begin by identifying the correct Deutsch connector for the application. Insert the plug into the connector until it reaches the lock-wedge position. Engage the lock-wedge mechanism to secure the plug in place. It is important to follow manufacturer guidelines to avoid common pitfalls, such as improper alignment or insufficient locking, which can compromise the connection 6.

Troubleshooting

Common issues with the Lock-Wedge, Deutsch Plug may include difficulty in insertion, insecure connections, or damage to the plug or connector. To troubleshoot these problems, first, ensure that the plug is correctly aligned with the connector. If the plug does not insert smoothly, check for obstructions or debris within the connector. For insecure connections, re-engage the lock-wedge mechanism to ensure it is fully locked. If damage is present, assess whether the plug or connector needs replacement 7.

Maintenance Tips

Routine maintenance of the Lock-Wedge, Deutsch Plug is important for ensuring its longevity and optimal performance. Regular inspection intervals should be established to check for signs of wear or damage. Cleaning the plug and connector contacts with an appropriate electrical contact cleaner can prevent corrosion and ensure a good connection. Following these maintenance practices will help maintain the reliability of the electrical system 8.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality engine and component solutions. The company’s product portfolio includes a wide range of engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of commercial trucking. Cummins’ reputation for quality and reliability is supported by its commitment to innovation and customer satisfaction, making it a trusted name in the industry 9.

Role of Part 3163105 Lock-wedge,deutsch Plug in Component Usage

The Part 3163105 Lock-wedge,deutsch Plug is an essential component in ensuring the secure and reliable connection of various electrical systems within engine assemblies. Its primary function is to maintain a robust and stable link between the wiring harness and other electrical components, which is vital for the consistent performance of the engine system 10.

Integration with Wiring Harness Repair Kit

When incorporated into a Wiring Harness Repair Kit, the Lock-wedge,deutsch Plug plays a significant role in restoring and maintaining the integrity of the electrical connections. The repair kit often includes various connectors, terminals, and wiring segments designed to replace or repair damaged sections of the wiring harness. The Lock-wedge,deutsch Plug ensures that these new connections are securely fastened, preventing any potential issues such as loose connections, which could lead to intermittent electrical faults or complete failure of the electrical system 11.

The secure fit provided by the Lock-wedge,deutsch Plug helps in maintaining the structural integrity of the wiring harness, which is subjected to vibrations and movements within the engine compartment. This stability is essential for the longevity and reliability of the electrical connections, ensuring that power and data signals are transmitted efficiently without interruption 12.

Furthermore, the Lock-wedge,deutsch Plug’s design allows for easy installation and removal, which is a significant advantage during maintenance or repair procedures. This feature simplifies the repair process, reducing the time and effort required to restore the electrical system to its optimal functioning state 13.

Conclusion

In summary, the Part 3163105 Lock-wedge,deutsch Plug is a key component in the reliable operation of engine systems, particularly when integrated with wiring harness repair kits. Its role in securing electrical connections ensures the consistent and efficient performance of the engine’s electrical systems 14.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems (Springer Vieweg, 2014).

↩ -

Tim Gilles, Automotive Service: Inspection, Maintenance, Repair: 2nd Edition (Cengage Learning, 2020).

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding (Cengage Learning, 2019).

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5659862, Engine B6.7 CM2670 B173B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.