This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

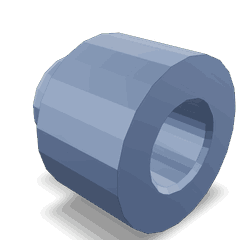

The 3376815 Expansion Plug Installer is a specialized tool designed by Cummins for the precise installation and removal of expansion plugs in commercial truck engines. This Cummins part is integral to maintaining the integrity and performance of engine components, ensuring that plugs are securely fitted without damage. Its role in routine maintenance and repair procedures underscores its significance in the upkeep of commercial vehicles.

Basic Concepts

Expansion plugs are utilized in engine maintenance to seal openings in engine blocks and other components, preventing fluid leaks and maintaining system pressure. The installation of these plugs requires precision to ensure a proper fit and seal. An installer tool, such as the 3376815, facilitates this process by providing the necessary force and alignment to insert or remove plugs without causing damage to the plug or the surrounding material 1.

Purpose and Functionality

The 3376815 is designed to streamline the process of installing and removing expansion plugs in truck engines. It plays a role in ensuring that plugs are correctly positioned and securely installed, which is vital for the engine’s operation and longevity. By using this tool, technicians can achieve consistent results, reducing the risk of improper installation that could lead to engine damage or failure 2.

Key Features

The 3376815 boasts several features that enhance its performance and durability. Its design incorporates elements that allow for precise alignment and application of force during plug installation. Constructed from high-quality materials, the tool is built to withstand the rigors of frequent use in a commercial setting. Additionally, its ergonomic design ensures ease of use, reducing technician fatigue during prolonged use 3.

Benefits

Utilizing the 3376815 offers several advantages. It improves the efficiency of plug installation processes, reducing the time required for maintenance tasks. This tool also contributes to the enhancement of engine performance and longevity by ensuring that expansion plugs are correctly installed, thereby maintaining the integrity of the engine’s sealing system. Furthermore, its use can lead to a reduction in maintenance costs over time by preventing the need for repairs due to improperly installed plugs 4.

Operational Guidelines

To ensure the correct usage of the 3376815, it is important to follow recommended practices and safety precautions. Begin by selecting the appropriate size of expansion plug for the application. Carefully align the installer with the plug and the opening, ensuring that the tool is perpendicular to the surface. Apply steady pressure to insert the plug, monitoring the process to avoid over-insertion. For removal, reverse the process, applying gentle pressure to extract the plug. Always wear appropriate personal protective equipment and ensure the engine is cool before beginning work 5.

Troubleshooting and Maintenance

Common issues with the 3376815 may include difficulty in plug alignment or insertion. To address these, verify that the correct size installer is being used and that the engine component is clean and free of debris. Regular maintenance of the tool, such as cleaning and inspecting for wear, will help ensure its longevity and effectiveness. Should the tool become damaged, it is advisable to replace it to maintain the quality of plug installations 6.

Conclusion

The 3376815 Expansion Plug Installer by Cummins is a vital tool for the maintenance and repair of commercial truck engines. Its precise design and robust construction ensure efficient and secure installation and removal of expansion plugs, contributing to the overall performance and longevity of engine components. By adhering to operational guidelines and performing regular maintenance, technicians can maximize the benefits of this Cummins part, ensuring optimal engine performance and reducing maintenance costs.

-

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF2.8 CM2220 AN. Bulletin Number 4022267.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISF2.8 CM2220 AN. Bulletin Number 4022267.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.