This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

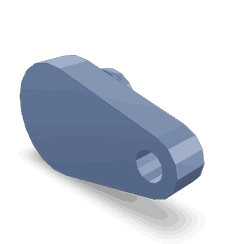

The Cummins O-Ring Plug 3976056 is a critical component designed to maintain the integrity of fluid systems in heavy-duty trucks. Its primary function is to provide a reliable seal in various applications, contributing to the efficient operation and maintenance of truck systems. Understanding its function and significance is essential for maintaining the performance and longevity of heavy-duty vehicles.

Basic Concepts of O-Ring Plugs

O-Ring Plugs are circular elastomeric seals that fit into a groove and compress during installation to create a seal. They are widely used in mechanical systems to prevent leaks and maintain system pressure. Their design allows them to accommodate minor misalignments and vibrations, making them suitable for dynamic environments like those found in heavy-duty trucks 1.

Purpose of the 3976056 O-Ring Plug

This Cummins part is specifically engineered to seal openings in fluid systems within trucks. It plays a role in maintaining the integrity of these systems by preventing fluid leaks and ensuring that system pressure is maintained. This plug is utilized in various applications, including engine components and other systems where fluid containment is necessary 2.

Key Features

The 3976056 O-Ring Plug is constructed from high-quality elastomeric materials, chosen for their durability and resistance to a range of operating conditions. Its design specifications include precise dimensions to ensure a snug fit within the designated grooves. Additionally, the plug may feature unique attributes such as enhanced resistance to chemicals and temperatures commonly encountered in truck operations 3.

Benefits

Utilizing the 3976056 O-Ring Plug offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and maintaining system pressure. Its durability ensures long-term performance, even under demanding conditions. Furthermore, the plug contributes to the overall reliability of the truck’s systems, supporting efficient operation and reducing maintenance needs 4.

Installation Process

Proper installation of the 3976056 O-Ring Plug involves several steps to ensure correct fitting and function. It is recommended to use appropriate tools to avoid damaging the plug during installation. The process includes cleaning the groove, lubricating the plug, and carefully inserting it into the groove to achieve the desired compression and seal 5.

Troubleshooting Common Issues

Common issues with O-Ring Plugs, such as leaks or failure, can often be traced to improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps may include inspecting the plug for signs of damage, ensuring correct installation, and replacing the plug if necessary to resolve leaks or system pressure issues 6.

Maintenance Tips

Regular maintenance of the 3976056 O-Ring Plug is important to ensure its continued effectiveness. This includes periodic inspections for signs of wear, checking for proper seating, and replacing the plug according to manufacturer recommendations or when signs of degradation are observed. Adhering to these practices helps maintain system integrity and performance 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its components, including the 3976056 O-Ring Plug.

Cummins O-Ring Plug 3976056 Compatibility

The Cummins O-Ring Plug part number 3976056 is designed to fit seamlessly with several of Cummins’ engine models. This part is integral in ensuring the sealing and integrity of various engine components, providing a reliable barrier against leaks and contamination.

B4.5 RGT Engines

The O-Ring Plug 3976056 is compatible with the B4.5 RGT engines. This compatibility ensures that the plug fits precisely in the designated areas, maintaining the engine’s operational efficiency and longevity.

ISB/ISD6.7 CM2150 SN Engines

For the ISB/ISD6.7 CM2150 SN engines, the O-Ring Plug 3976056 is engineered to fit into specific points within the engine architecture. This ensures that the plug provides an effective seal, contributing to the overall performance and reliability of the engine.

ISBE4 CM850 Engines

The O-Ring Plug 3976056 is also suitable for the ISBE4 CM850 engines. Its design allows it to integrate smoothly into the engine’s structure, providing a critical sealing function that is essential for maintaining engine integrity.

By ensuring a proper fit and function, the O-Ring Plug 3976056 plays a crucial role in the maintenance and performance of these Cummins engines.

Role of Part 3976056 O-Ring Plug in Engine Systems

The part 3976056 O-Ring Plug is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to seal and prevent leaks in critical areas, ensuring that the engine operates smoothly and efficiently.

Breather System

In the breather system, the O-Ring Plug is used to seal connections and passages that allow air to enter and exit the crankcase. This helps in maintaining the correct pressure within the crankcase, which is vital for the proper functioning of the engine. By preventing air leaks, the O-Ring Plug ensures that the breather system can effectively manage moisture and contaminants, prolonging the life of the engine components.

Crankcase

Within the crankcase, the O-Ring Plug plays a significant role in sealing various ports and passages. This sealing is important for maintaining the lubrication system’s efficiency. By preventing oil leaks, the O-Ring Plug ensures that the crankcase maintains the necessary oil levels, which are essential for lubricating moving parts and reducing friction. This, in turn, helps in preventing wear and tear on critical engine components.

Module Connections

In engine control modules and other electronic components, the O-Ring Plug is used to seal connections that are exposed to various fluids and environmental conditions. This sealing is important for protecting sensitive electronic components from moisture and contaminants, which can cause malfunctions or failures. By ensuring a tight seal, the O-Ring Plug helps in maintaining the reliability and performance of the engine control system.

Engine Control System

The engine control system relies on precise fluid management and sealed connections to operate efficiently. The O-Ring Plug is used in various points within this system to prevent leaks and ensure that fluids are directed correctly. This is particularly important in fuel injection systems, where precise control over fuel delivery is necessary for optimal engine performance. By maintaining sealed connections, the O-Ring Plug contributes to the overall efficiency and reliability of the engine control system.

Conclusion

The Cummins O-Ring Plug 3976056 is a vital component in the maintenance and performance of heavy-duty truck engines. Its role in sealing critical areas, preventing leaks, and maintaining system pressure is essential for the efficient operation of engine systems. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are key to ensuring the longevity and reliability of these systems.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016)

↩ -

Forbes Aird, Bosch Fuel Injection Systems (HP Books, 2001)

↩ -

Sean Bennett, Modern Diesel Technology: Light Duty Diesels (Cengage Learning, 2012)

↩ -

Barry Kluczyk, How to Rebuild Any Automotive Engine (CarTech, 2008)

↩ -

Cummins Inc., General Information, Bulletin Number 4915556, Owners Manual

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016)

↩ -

Sean Bennett, Modern Diesel Technology: Light Duty Diesels (Cengage Learning, 2012)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.