This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4361952 O-Ring Plug is a critical component in heavy-duty truck maintenance and operation. This part ensures the proper functioning of various systems within a truck, particularly in maintaining seals and preventing leaks. Its role is significant in the context of heavy-duty truck maintenance, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of O-Ring Plugs

O-ring plugs are circular elastomeric seals that fit into a groove and create a seal when compressed. They are widely used in mechanical systems to prevent the leakage of fluids and gases. O-ring plugs function by deforming under pressure to fill the gap between mating surfaces, thus ensuring a tight seal. Their applications range from simple plumbing fixtures to complex automotive and industrial machinery 1.

Purpose of the Cummins 4361952 O-Ring Plug

The Cummins 4361952 O-Ring Plug serves a specific function within the operation of a truck. It is designed to seal openings in various components, such as fuel systems, hydraulic systems, and engine parts. By providing a reliable seal, this O-ring plug helps maintain system integrity, prevent leaks, and ensure that fluids and gases remain contained within their designated pathways.

Key Features

The Cummins 4361952 O-Ring Plug is characterized by several key features that enhance its performance. It is typically made from durable elastomeric materials, such as nitrile rubber, which offer excellent resistance to oils, fuels, and other chemicals. The design of the O-ring plug includes precise dimensions to ensure a proper fit within the designated groove, and it may feature unique properties such as anti-extrusion elements to withstand high pressures.

Benefits

Using the Cummins 4361952 O-Ring Plug offers several advantages. Its high-quality material composition ensures improved sealing efficiency, which is vital for maintaining system performance. The durability of the O-ring plug means it can withstand harsh operating conditions, including temperature fluctuations and exposure to various chemicals. Additionally, its resistance to wear and tear contributes to the longevity of the seal, reducing the need for frequent replacements 2.

Installation Process

Installing the Cummins 4361952 O-Ring Plug requires careful attention to detail to ensure a proper seal. The installation process involves cleaning the groove where the O-ring will be placed to remove any debris or contaminants. The O-ring should be lubricated with a compatible lubricant to facilitate insertion and prevent damage. It is important to avoid twisting or pinching the O-ring during installation, as this can compromise its sealing ability. Once installed, the system should be tested for leaks to confirm the integrity of the seal.

Troubleshooting Common Issues

Common issues with O-ring plugs include leaks, which can be caused by improper installation, damage to the O-ring, or degradation of the material over time. To address these problems, it is important to inspect the O-ring for signs of wear or damage and replace it if necessary. Ensuring that the groove is clean and free of contaminants before installation can also help prevent leaks. Additionally, using the correct lubricant during installation can reduce the risk of damage to the O-ring.

Maintenance Tips

Regular maintenance of the Cummins 4361952 O-Ring Plug is important to ensure its continued effectiveness. This includes periodic inspection of the O-ring for signs of wear, cracking, or deformation. Replacement guidelines should be followed to ensure that the O-ring is replaced before it fails. Additionally, keeping the groove clean and free of contaminants will help maintain the integrity of the seal.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of various applications 3.

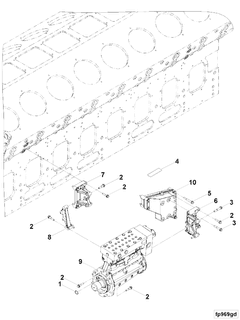

Cummins Engine Part 4361952: O-Ring Plug Compatibility

The O-Ring Plug, identified by part number 4361952, manufactured by Cummins, is a critical component in ensuring the sealing integrity of various engine systems. This part is designed to fit seamlessly within the engine architecture of specific Cummins engines, ensuring that the engine operates efficiently and reliably.

Engine Compatibility

The O-Ring Plug part number 4361952 is compatible with the following Cummins engines:

- QSK95 CM2350 K111

- QSK95 CM2350 K113

These engines, while sharing a common base model, may have slight variations in their configurations and requirements. The O-Ring Plug is engineered to meet the specific sealing needs of these engines, ensuring that it provides an effective barrier against leaks and contaminants.

Application and Installation

The installation of the O-Ring Plug is a meticulous process that requires precision to ensure optimal performance. Typically, this part is used in areas where a secure seal is necessary to prevent the escape of fluids or gases. The O-Ring Plug is designed to fit snugly into designated areas within the engine, providing a reliable seal that can withstand the operational stresses of the engine.

Importance of Proper Installation

Proper installation of the O-Ring Plug is crucial for the longevity and performance of the engine. An improperly installed O-Ring Plug can lead to leaks, which can compromise engine efficiency and potentially cause damage over time. Technicians and mechanics must follow the manufacturer’s guidelines and use the appropriate tools to ensure that the O-Ring Plug is installed correctly.

Maintenance and Replacement

Regular maintenance checks should be conducted to ensure that the O-Ring Plug remains in good condition. Over time, O-Ring Plugs can degrade due to exposure to heat, pressure, and various engine fluids. If any signs of wear or damage are detected, the O-Ring Plug should be replaced promptly to maintain the integrity of the engine’s sealing system.

Role of Part 4361952 O-Ring Plug in Fuel System Components

The part 4361952 O-Ring Plug is integral to maintaining the integrity and efficiency of various fuel system components. In the Fuel Injection Pump, this O-Ring Plug ensures a tight seal around the injection nozzles, preventing fuel leaks and maintaining consistent fuel pressure. This is essential for precise fuel delivery and optimal engine performance.

Within the Fuel Pump, the O-Ring Plug plays a significant role in sealing connections and preventing fuel leakage. It ensures that the fuel pump operates efficiently by maintaining a secure seal around the pump housing and fuel lines. This helps in delivering a steady fuel supply to the engine.

In a Fuel Pump Kit, the inclusion of the O-Ring Plug is vital for the assembly and functionality of the kit. It ensures that all components within the kit are sealed properly, which is necessary for the reliable operation of the fuel pump system. This contributes to the overall durability and performance of the fuel pump kit.

For general Pump applications within the fuel system, the O-Ring Plug is used to seal various connections and fittings. This prevents fuel from escaping and ensures that the pump can operate under the required pressure conditions. Proper sealing is essential for the longevity and efficiency of the pump.

Lastly, in the broader context of the Fuel system, the O-Ring Plug is a small but essential component that contributes to the system’s overall reliability. By ensuring that all connections are sealed, it helps maintain the integrity of the fuel supply, which is fundamental for the engine’s consistent and efficient operation.

Conclusion

The Cummins 4361952 O-Ring Plug is a vital component in the maintenance and operation of heavy-duty trucks. Its role in sealing various systems ensures the efficiency and reliability of the vehicle. Proper installation, regular maintenance, and understanding its compatibility with specific Cummins engines are essential for optimal performance. By ensuring the integrity of seals within the fuel system and other components, this part contributes significantly to the overall functionality and longevity of the truck.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.