This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

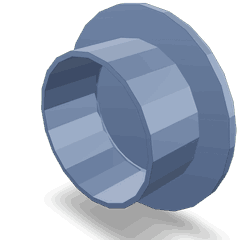

The Cummins 4378508 Cavity Plug is a specialized component designed for commercial trucks, aimed at maintaining engine integrity by preventing fluid leakage and contamination.

Basic Concepts of Cavity Plugs

A cavity plug is a crucial component in engine systems, designed to seal openings or cavities within the engine block or other parts. This sealing action prevents contaminants from entering and fluids from escaping, thereby maintaining engine cleanliness and efficiency 1.

Purpose of the 4378508 Cavity Plug

This Cummins part is designed to fit into specific openings within a truck’s engine or components, providing a secure seal to prevent fluid leakage and the entry of dirt or debris. This strategic placement ensures critical areas remain protected, contributing to efficient engine operation 2.

Key Features

The 4378508 Cavity Plug is constructed from durable materials to withstand harsh engine conditions. It features precise threading and a tight seal, crucial for effective sealing. Additional features may include anti-corrosion coatings or specialized shapes for optimal fit and function 3.

Benefits

Using the 4378508 Cavity Plug contributes to improved engine performance by maintaining the integrity of the engine’s internal environment. It aids in the longevity of engine components by preventing contamination and fluid loss, and can lead to maintenance cost savings by reducing the need for repairs related to fluid leaks or component damage 4.

Installation Process

Installing this part requires careful attention to ensure a secure fit. The process involves cleaning the cavity, selecting the appropriate plug size, and using the correct tools for installation. Following manufacturer guidelines ensures the plug is seated properly, providing an effective seal without damaging surrounding components.

Troubleshooting Common Issues

Common issues with cavity plugs include leaks or improper seating. Inspecting the plug and cavity for signs of damage or wear is important. If a leak is detected, the plug may need to be replaced or reseated. Ensuring the cavity is clean and free of debris before installation can help prevent these issues.

Maintenance Tips

Regular maintenance checks are recommended to ensure the 4378508 Cavity Plug remains in optimal condition. This includes periodic inspections for signs of wear, damage, or leaks. Following manufacturer-recommended inspection intervals can help identify issues early, allowing for timely repairs or replacements to maintain engine efficiency and longevity.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s history of excellence and dedication to advancing technology underscores its position as a trusted partner in the commercial trucking sector.

Role of the 4378508 Cavity Plug in Flywheel Housing

The 4378508 Cavity Plug is instrumental in maintaining the integrity and functionality of the flywheel housing within an engine system. Positioned within the flywheel housing, this plug seals off specific cavities that are not in use during operation, preventing contaminants from entering these sensitive areas. It also helps maintain pressure equilibrium within the flywheel housing, essential for the proper functioning of the flywheel. Furthermore, the plug contributes to the overall structural stability of the flywheel housing by filling unused cavities, ensuring the housing maintains its shape and strength under dynamic loads and vibrations experienced during engine operation.

Conclusion

The 4378508 Cavity Plug, though a small component, plays a significant role in protecting, stabilizing, and ensuring the efficient operation of the flywheel housing within an engine system. Its design and manufacturing by Cummins reflect the company’s commitment to quality and precision, making it an essential part for maintaining engine performance and longevity.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.