This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4934709 O-Ring Plug is a specialized component designed for use in commercial trucks. Its primary function is to provide a secure seal in various engine and system applications, ensuring the integrity of fluid and pressure systems within the vehicle.

Basic Concepts of O-Ring Plugs

An O-Ring Plug is a type of sealing device that utilizes an O-ring—a toroidal (ring-shaped) elastomer with a circular cross-section—to create a seal. When compressed within a gland, the O-ring deforms to fill the space between the mating surfaces, preventing the leakage of fluids or gases. O-Ring Plugs are commonly used in mechanical systems to seal ports, passages, and connections, ensuring that systems operate efficiently and without leaks 1.

Purpose of the 4934709 O-Ring Plug

This Cummins part plays a specific role in the operation of commercial trucks by sealing critical points within the engine or other systems. This plug helps maintain the pressure and fluid integrity necessary for the proper functioning of the engine components, contributing to the overall performance and reliability of the truck 2.

Key Features

The 4934709 is characterized by several key features:

- Material Composition: The O-ring is typically made from high-quality elastomer materials, such as nitrile rubber, which offer excellent resistance to oils, fuels, and various chemicals commonly found in engine environments.

- Design Specifications: The plug is designed to fit specific gland sizes and configurations, ensuring a precise and effective seal.

- Unique Attributes: The plug may include features such as anti-extrusion elements to prevent the O-ring from being forced out of the gland under high pressure.

Benefits

Using this Cummins part offers several benefits:

- Improved Sealing: The O-ring provides a reliable seal, preventing leaks that could lead to system failures or inefficiencies.

- Durability: The high-quality materials used in the O-ring ensure long-lasting performance even under demanding conditions.

- Performance Enhancements: By maintaining system integrity, the plug contributes to the overall efficiency and reliability of the truck’s engine and related systems 3.

Installation Process

Proper installation of the 4934709 involves the following steps:

- Prepare the Gland: Ensure the gland is clean and free of any debris or old sealant.

- Lubricate the O-Ring: Apply a compatible lubricant to the O-ring to facilitate installation and reduce the risk of damage.

- Insert the Plug: Carefully place the O-Ring Plug into the gland, ensuring it is seated correctly and evenly.

- Check the Seal: Verify that the plug is properly installed by checking for any signs of leakage or uneven seating.

Troubleshooting Common Issues

Common problems associated with O-Ring Plugs include leaks and extrusion. To address these issues:

- Inspect for Damage: Check the O-ring for signs of wear, cuts, or deformation.

- Ensure Proper Installation: Verify that the plug is correctly seated and that the gland is clean and undamaged.

- Replace if Necessary: If the O-ring is damaged or worn, replace the plug with a new one to restore the seal.

Maintenance Tips

To ensure the longevity and optimal performance of the 4934709:

- Regular Inspections: Periodically check the plug for signs of wear or damage.

- Cleaning: Keep the gland and surrounding areas clean to prevent contamination that could affect the seal.

- Lubrication: Ensure that the O-ring is properly lubricated during installation to maintain its flexibility and sealing capabilities.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and transportation markets worldwide, providing reliable and efficient power systems for various applications 4.

Application in Cummins Engines

B4.5 RGT Engines

The O-Ring Plug is specifically designed to fit seamlessly into the B4.5 RGT engines. This engine model is known for its reliability and efficiency, often used in various industrial and commercial applications. The O-Ring Plug in this engine ensures that the sealing system remains intact, preventing any fluid or gas leaks that could compromise engine performance.

Other Cummins Engines

While the primary focus here is on the B4.5 RGT engines, the O-Ring Plug is also compatible with other Cummins engine models. This versatility makes it a valuable component across different engine types, ensuring consistent performance and reliability. The O-Ring Plug’s design allows it to fit snugly into the designated areas of the engine, providing a secure seal that is essential for the engine’s operation.

Engine Group Compatibility

The O-Ring Plug is part of a broader range of components designed for Cummins engines. It is engineered to work with various engine groups, ensuring that it meets the specific needs of each engine model. This compatibility is crucial for maintaining the engine’s efficiency and longevity, as it allows for easy replacement and maintenance without requiring extensive modifications.

Role of Part 4934709 O-Ring Plug in Engine Systems

The 4934709 is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to provide a secure seal in areas where fluids or gases must be contained or where external contaminants need to be prevented from entering sensitive engine components.

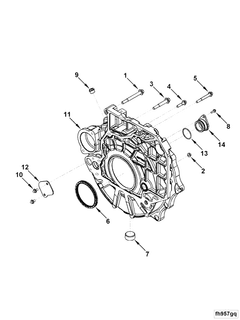

In the flywheel housing, the 4934709 ensures that the housing remains sealed, preventing any leakage of lubricants or other fluids that are vital for the smooth operation of the flywheel. This seal is important for maintaining the proper lubrication and cooling of the flywheel, which in turn ensures consistent performance and longevity of the component.

When installed in the housing of other engine components, the O-Ring Plug plays a similar role. It creates a barrier that keeps out dirt, moisture, and other contaminants that could otherwise lead to wear, corrosion, or failure of the internal parts. This is particularly important in environments where the engine is exposed to harsh conditions or where the housing contains sensitive electronic or mechanical components.

In the context of the flywheel, the 4934709 helps in maintaining the structural integrity of the assembly. By ensuring a tight seal, it prevents any unwanted movement or play within the flywheel system, which could otherwise result in imbalanced operation and increased wear on connected components such as the crankshaft and clutch system.

Overall, the 4934709 is a small yet significant part that contributes to the reliable and efficient functioning of engine systems by providing necessary seals and protections against external elements.

Conclusion

The Cummins 4934709 O-Ring Plug is a vital component in the maintenance and operation of commercial truck engines. Its role in providing secure seals, preventing leaks, and protecting sensitive engine components from contaminants ensures the reliability and efficiency of the engine systems. Proper installation, regular maintenance, and timely replacement of this part are essential for the optimal performance and longevity of the engine.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.