This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

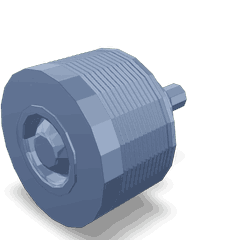

The Idler (Top Level Assembly) Pulley, Part #3267045 by Cummins, is designed to enhance the operational efficiency of truck systems. Cummins, a renowned manufacturer in the diesel engine industry, produces this pulley to ensure reliable performance in various truck applications. This pulley is integral to maintaining the functionality and efficiency of the truck’s belt drive system.

Basic Concepts

Idler pulleys are fundamental components within a belt drive system. They function by supporting and guiding the belt, ensuring it remains properly aligned and tensioned. This alignment and tension are vital for the efficient transfer of power from the engine to various components such as the alternator, water pump, and air conditioning compressor. By maintaining optimal belt tension, idler pulleys contribute to the smooth and reliable operation of these components 1.

Purpose of the Idler (Top Level Assembly) Pulley

The Idler (Top Level Assembly) Pulley plays a specific role in the operation of a truck by maintaining the correct tension of the belt within the drive system. Proper belt tension is crucial for the efficient operation of the truck’s components, as it ensures that power is transmitted effectively without slippage or excessive wear. This pulley helps in distributing the load evenly across the belt, thereby enhancing the overall efficiency and longevity of the belt drive system 2.

Key Features

The Idler (Top Level Assembly) Pulley is characterized by its robust design and high-quality materials. It is constructed using durable materials that can withstand the harsh conditions typically encountered in truck operations. The pulley features a precision-machined bearing and a high-strength housing, which contribute to its reliable performance and longevity. Additionally, its design allows for easy integration into the truck’s belt drive system, ensuring a seamless fit and operation.

Benefits

The advantages of using the Idler (Top Level Assembly) Pulley include improved belt life, reduced maintenance requirements, and enhanced system reliability. By maintaining optimal belt tension, this pulley helps in reducing belt wear and tear, leading to longer belt life. Additionally, its design minimizes the need for frequent maintenance, allowing for more reliable and uninterrupted truck operations. The overall system reliability is enhanced, contributing to better performance and efficiency 3.

Installation and Integration

To install the Idler (Top Level Assembly) Pulley, begin by locating the appropriate position within the truck’s belt drive system. Ensure the engine is off and the belt is loose. Align the pulley with the mounting brackets and secure it in place using the provided fasteners. Once installed, adjust the belt tension according to the manufacturer’s specifications to ensure optimal performance and longevity of the belt drive system.

Troubleshooting Common Issues

Common issues associated with idler pulleys include noise, vibration, or belt misalignment. These problems can often be traced to improper installation, wear and tear, or insufficient lubrication. To address these issues, inspect the pulley for signs of damage or wear, ensure it is properly aligned and tensioned, and apply the recommended lubricant to the bearing. If problems persist, consider replacing the pulley to restore optimal system performance.

Maintenance Tips

Regular maintenance practices are vital for ensuring the longevity and efficient operation of the Idler (Top Level Assembly) Pulley. Inspect the pulley periodically for signs of wear or damage, and ensure it remains properly aligned and tensioned. Lubricate the bearing as per the manufacturer’s guidelines to reduce friction and wear. Following these maintenance tips will help in maintaining the performance and reliability of the pulley and the overall belt drive system.

Cummins Overview

Cummins Inc. is a leading manufacturer with a rich history in diesel engine production. The company is recognized for its expertise, innovation, and commitment to quality in the commercial truck industry. Cummins’ dedication to advancing technology and improving engine performance has established it as a trusted name in the industry, providing reliable and high-performance components like the Idler (Top Level Assembly) Pulley.

Compatibility with Cummins Engines

The Idler (Top Level Assembly) Pulley is compatible with several Cummins engine models, including:

- ISM CM570

- L10 CELECT

- L10 MECHANICAL

- M11 CELECT PLUS

- M11 MECHANICAL

- QSM11 CM570

Grouping by Engine Series

ISM Series:

- ISM CM570: This engine variant features advanced emissions control technologies and is often used in heavy-duty applications. The Idler (Top Level Assembly) Pulley ensures the belt system operates smoothly, maintaining the necessary tension for optimal performance.

L10 Series:

- L10 CELECT: This model is known for its electronic control system, which enhances fuel efficiency and reduces emissions. The Idler (Top Level Assembly) Pulley plays a crucial role in the belt drive system, ensuring that all engine accessories receive the correct power and operation.

- L10 MECHANICAL: This version relies on mechanical controls rather than electronic systems. The Idler (Top Level Assembly) Pulley is essential for maintaining belt tension and alignment, ensuring reliable operation of the engine’s accessories.

M11 Series:

- M11 CELECT PLUS: This engine model combines advanced emissions control with robust performance. The Idler (Top Level Assembly) Pulley is integral to the belt drive system, ensuring that the engine’s accessories are powered efficiently.

- M11 MECHANICAL: This variant uses mechanical controls for its operation. The Idler (Top Level Assembly) Pulley ensures that the belt system maintains the correct tension and alignment, crucial for the smooth operation of the engine’s accessories.

QSM11 Series:

- QSM11 CM570: This engine is designed for high-performance applications, often found in construction and agricultural equipment. The Idler (Top Level Assembly) Pulley is essential for maintaining the belt system’s integrity, ensuring that all engine accessories receive the necessary power and operation.

The Idler (Top Level Assembly) Pulley’s design and material ensure durability and longevity, making it a reliable choice for maintaining the engine’s belt drive system across various Cummins engine models.

Role of Part 3267045 Idler (Top Level Assembly) Pulley in Engine Systems

The Idler (Top Level Assembly) Pulley, identified by part number 3267045, is an integral component in the efficient operation of various engine systems. Its primary function is to maintain tension in the drive belt system, ensuring optimal performance and longevity of the belt and associated components.

Drive System Integration

In the drive system, the idler pulley works in conjunction with the crankshaft and other pulleys to keep the drive belt properly tensioned. This tension is vital for the smooth transfer of power from the engine to auxiliary components such as the alternator, water pump, and air conditioning compressor. Without adequate tension, the drive belt may slip, leading to inefficient power transfer and potential damage to the belt and pulleys.

Fan and Cooling System

The idler pulley also plays a significant role in the fan and cooling system. By maintaining the correct tension on the drive belt, it ensures that the fan operates efficiently. The fan is responsible for drawing air through the radiator to cool the engine. Inadequate belt tension can result in the fan not spinning at the required speed, leading to overheating issues and reduced engine performance.

Fan Support and Structural Integrity

In systems where the fan is supported by a fan support structure, the idler pulley contributes to the structural integrity of this assembly. Proper belt tension ensures that the fan support does not experience undue stress or vibration, which could lead to premature wear or failure of the support components.

Package and Product Installation

During the package and product installation phase, the idler pulley is often included as part of a comprehensive belt and pulley kit. Its installation is a key step in ensuring that the entire drive system is correctly assembled and functions as intended. Engineers and mechanics must pay close attention to the alignment and tensioning of the idler pulley during installation to avoid issues down the line.

Conclusion

In summary, the Idler (Top Level Assembly) Pulley, part number 3267045, is a vital component in maintaining the efficiency and reliability of engine systems. Its role in tensioning the drive belt impacts various interconnected components, from the drive system to the cooling fan, ensuring that the engine operates smoothly and effectively.

-

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.