This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

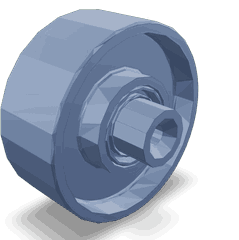

The Cummins 3285717 Idler Pulley is a critical component in commercial trucks, designed to ensure the efficient operation of the belt drive system. This part plays a significant role in maintaining the efficiency and reliability of the truck’s engine and auxiliary systems.

Basic Concepts of Idler Pulleys

An idler pulley, such as the Cummins 3285717, is used in belt drive systems to guide and tension the belt. It ensures the belt remains properly aligned and tensioned, which is essential for efficient power transmission and reducing wear on both the belt and the driven components 1.

Purpose of the Cummins 3285717 Idler Pulley

This Cummins part is designed to maintain the tension and alignment of belts in commercial truck engines. By ensuring proper tension, it facilitates efficient power transmission to components such as the alternator, water pump, and air conditioning compressor. This reduces belt slippage and wear, enhancing the overall performance and longevity of the belt drive system 2.

Key Features

The Cummins 3285717 Idler Pulley is constructed from high-quality materials to ensure durability and reliable performance. It features a robust bearing system for smooth rotation, a precision-machined surface for optimal belt contact, and a design that accommodates various belt sizes and configurations. These attributes contribute to the pulley’s ability to withstand the rigors of commercial truck operation 3.

Benefits of Using the Cummins 3285717 Idler Pulley

Utilizing this part offers several advantages. It contributes to improved belt life by maintaining consistent tension and alignment, which reduces the likelihood of belt failure. Additionally, the pulley’s design minimizes maintenance requirements, as its durable construction and precise engineering reduce the need for frequent adjustments or replacements. Enhanced system efficiency is another benefit, as proper belt tension and alignment lead to more effective power transmission and reduced energy loss.

Installation Considerations

When installing the Cummins 3285717 Idler Pulley, it is important to follow guidelines and best practices to ensure proper function. Preparatory steps include ensuring the engine is cool and the belt drive system is free of debris. The necessary tools for installation may include a socket wrench for securing the pulley and a tension gauge for checking belt tension. Alignment procedures should be carefully followed to ensure the pulley is correctly positioned relative to the belt and other components.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3285717 Idler Pulley involves periodic inspection for signs of wear or damage, such as excessive noise, vibration, or belt slippage. Common issues may include bearing wear or misalignment, which can be addressed by replacing worn components or readjusting the pulley. Troubleshooting steps should include checking belt tension and alignment, inspecting the pulley bearings, and ensuring that all fasteners are secure.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial transportation.

Idler Pulley Fitment for Cummins Engines

The Idler Pulley part number 3285717, manufactured by Cummins, is designed to fit several of their engine models. This pulley plays a role in the engine’s belt-driven systems, ensuring the proper tension and alignment of the serpentine belt. Here is how it fits with the specified engines:

ISL9 CM2150 SN, ISM CM570, ISM CM570/870, ISM CM876

The Idler Pulley 3285717 is compatible with the ISL9 CM2150 SN, ISM CM570, ISM CM570/870, and ISM CM876 engines. These engines are part of Cummins’ range of medium-duty and heavy-duty diesel engines, known for their reliability and performance in various applications. The pulley is engineered to fit seamlessly into the belt routing systems of these engines, ensuring efficient power transfer and minimizing wear on the belt.

M11 CELECT PLUS

The M11 CELECT PLUS engine also accommodates the Idler Pulley 3285717. This engine is designed for on-highway applications, providing a balance of power, efficiency, and low emissions. The pulley’s design ensures it integrates well with the M11 CELECT PLUS’s belt system, maintaining optimal belt tension and alignment.

By using the Idler Pulley 3285717, these engines benefit from improved operational efficiency and longevity of the belt system components.

Role of Part 3285717 Idler Pulley in Engine Systems

The idler pulley, designated as part 3285717, is integral to the efficient operation of various engine systems. It is strategically positioned to interact with multiple components, ensuring smooth and consistent performance.

Interaction with the Compressor

In systems where an air conditioning compressor is present, the idler pulley assists in maintaining the proper tension of the belt that drives the compressor. This ensures that the compressor operates efficiently, allowing for optimal refrigerant circulation and cooling performance.

Refrigerant System Support

By ensuring the compressor belt remains taut, the idler pulley indirectly supports the refrigerant system. Consistent belt tension prevents slippage, which could otherwise lead to inefficient refrigerant compression and reduced cooling efficiency.

Mounting and Structural Integration

The idler pulley is often mounted on a bracket that is part of the engine’s accessory drive system. This mounting setup allows it to work in concert with other pulleys and components, contributing to the overall structural integrity and balance of the engine’s accessory drive system.

Collaboration with the Alternator

In many engine configurations, the alternator is driven by the same belt system that the idler pulley tension maintains. Proper tension ensures that the alternator can spin at the correct speed to generate electricity, powering the vehicle’s electrical systems and recharging the battery.

Synergy with the Tensioner

The idler pulley works in tandem with the automatic tensioner to maintain consistent belt tension across all driven components. This collaboration is essential for the longevity of the belt and the efficient operation of all accessories it drives.

Belt Maintenance and Performance

The primary role of the idler pulley is to keep the belt properly aligned and tensioned. This not only enhances the belt’s lifespan but also ensures that all connected components, such as the compressor, alternator, and tensioner, operate within their designed parameters, leading to improved overall engine performance and reliability.

Conclusion

The Cummins 3285717 Idler Pulley is a vital component in the maintenance and efficiency of commercial truck engines. Its design and features ensure proper belt tension and alignment, contributing to the longevity and performance of the engine’s accessory systems. Proper installation, maintenance, and understanding of its role in the engine system are crucial for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.