This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

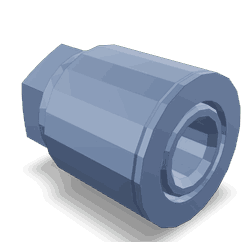

The 3376085 Pulley Installer, manufactured by Cummins, is a specialized tool designed for the installation and removal of pulleys in commercial trucks. Cummins, a well-established name in the automotive industry, is renowned for its commitment to quality and innovation in manufacturing components for commercial vehicles. This Cummins part holds significance in the realm of truck maintenance and operation, offering a solution to streamline the process of pulley management within the engine system.

Purpose and Function

The 3376085 serves a pivotal role in the operation and maintenance of commercial trucks by facilitating the installation and removal of pulleys. It ensures that pulleys are securely fastened and properly aligned, which is vital for maintaining the correct tension of belts within the engine system. Proper belt tension is essential for the efficient transfer of power and the smooth operation of various engine components. Additionally, the tool aids in aligning pulleys accurately, which helps in preventing undue wear on belts and other components, thereby contributing to the overall reliability and performance of the engine 1.

Key Features

This Cummins part is designed with several key features that enhance its performance and durability. Crafted from high-quality materials, it is built to withstand the rigors of frequent use in a commercial setting. Its design allows for compatibility with a wide range of pulley sizes, making it a versatile tool for various applications. The tool is engineered for ease of use, featuring ergonomic handles and a straightforward mechanism that simplifies the installation and removal process. Furthermore, it is designed to integrate seamlessly with other tools and equipment, allowing for a more streamlined workflow during maintenance tasks 2.

Benefits

Users of the 3376085, including mechanics, engineers, and fleet operators, can reap several benefits from its use. The tool significantly improves efficiency in maintenance tasks by reducing the time required for pulley installation and removal. This efficiency translates to reduced downtime for trucks, allowing fleets to maintain their operational schedules with minimal interruption. Additionally, by ensuring proper belt tension and alignment, the 3376085 contributes to the overall performance and longevity of the engine, potentially reducing the need for frequent repairs and replacements 3.

Troubleshooting and Maintenance

While the 3376085 is designed for durability and ease of use, regular maintenance is recommended to ensure optimal performance. Common issues may include wear on the tool’s surfaces or misalignment of its components. Troubleshooting steps may involve cleaning the tool thoroughly, lubricating moving parts, and inspecting for any signs of wear or damage. Regular maintenance not only prolongs the life of the tool but also ensures that it continues to perform its function effectively, contributing to the efficiency and reliability of truck maintenance operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s commitment to advancing technology and improving the efficiency of commercial vehicles is evident in its wide range of products, including the 3376085. Cummins’ dedication to excellence in manufacturing is a testament to its role as a trusted partner in the commercial truck industry.

Role of Part 3376085 Pulley Installer in Engine Systems

The 3376085 Pulley Installer is an essential tool designed to facilitate the precise installation and alignment of pulleys within various engine systems. Its application ensures that pulleys are correctly positioned, which is fundamental for the efficient operation of the engine’s accessory drive systems.

Integration with Accessory Drive Systems

When integrating with accessory drive systems, the Pulley Installer ensures that components such as the alternator, power steering pump, and air conditioning compressor are accurately aligned. Proper alignment is necessary to prevent belt wear, reduce noise, and enhance the overall performance and longevity of these accessories.

Application in Timing Systems

In timing systems, the Pulley Installer plays a significant role in the installation of timing belt or chain tensioner pulleys. Accurate placement of these pulleys is vital for maintaining the correct timing between the crankshaft and camshaft, which directly influences engine performance and reliability.

Use with Idler and Guide Pulleys

For idler and guide pulleys, the Pulley Installer ensures these components are correctly installed to maintain the proper tension and path of the drive belts. This is important for the smooth operation of the engine’s accessory systems and for preventing belt slippage or failure.

Importance in Supercharger and Turbocharger Systems

In supercharger and turbocharger systems, the Pulley Installer is used to install drive pulleys that connect to the engine’s crankshaft or accessory drive system. Accurate installation is essential for the efficient transfer of power to these forced induction systems, which directly impacts engine performance and boost levels.

Role in Variable Valve Timing Systems

Variable Valve Timing (VVT) systems often incorporate pulleys that adjust the timing of the camshaft. The Pulley Installer ensures these pulleys are correctly installed, allowing for precise control over valve timing, which is crucial for optimizing engine efficiency and power output.

Application in Serpentine Belt Systems

In serpentine belt systems, the Pulley Installer is used to install and align multiple pulleys that drive various engine accessories with a single belt. Proper alignment is key to ensuring the belt runs true, reducing wear, and preventing accessory failure.

Use with Water Pump and Oil Pump Pulleys

For water pump and oil pump pulleys, the Pulley Installer ensures these critical components are correctly installed. This is important for maintaining the proper flow of coolant and oil, which are essential for engine cooling and lubrication.

By ensuring the accurate installation and alignment of pulleys across these various engine systems, the 3376085 Pulley Installer contributes to the overall efficiency, performance, and reliability of the engine.

Conclusion

The 3376085 Pulley Installer is a vital tool in the maintenance and operation of commercial trucks, offering significant benefits in terms of efficiency, performance, and reliability. Its design and features make it a durable and versatile solution for various engine systems, ensuring that pulleys are correctly installed and aligned. Regular maintenance of this Cummins part is recommended to ensure its optimal performance, contributing to the overall efficiency and reliability of truck maintenance operations.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.