This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

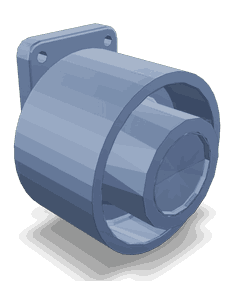

The Cummins 3638640 Idler Pulley is a component designed for use in heavy-duty trucks. Its purpose is to maintain the proper tension and alignment of the belts within the engine and accessory drive system. This ensures efficient operation of various truck components, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley that does not drive a component directly but instead supports and guides the belt within a belt-driven system. Its function is to keep the belt properly tensioned and aligned, which is vital for the efficient operation of the engine and its accessories 1. By maintaining the correct belt tension, the idler pulley helps to reduce slippage and wear, ensuring that power is effectively transmitted to components such as the alternator, water pump, and air conditioning compressor.

Purpose of the 3638640 Idler Pulley

The Cummins 3638640 Idler Pulley plays a specific role in the truck’s engine and accessory drive system. It is involved in maintaining the proper tension and alignment of the belts that drive various accessories. This ensures that these components receive consistent power transmission, which is necessary for their efficient operation. Proper belt tension and alignment also help to minimize wear on both the belts and the pulleys, contributing to the longevity of the system.

Key Features

The Cummins 3638640 Idler Pulley is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and corrosion, ensuring long-term reliability. The pulley’s design includes precision-machined surfaces and a robust bearing system, which allows for smooth operation and reduced friction 2. Additionally, the pulley is engineered to withstand the high loads and harsh conditions typical of heavy-duty truck applications.

Benefits of Using the 3638640 Idler Pulley

Using the Cummins 3638640 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment, which reduces the risk of belt slippage and premature wear. This, in turn, leads to reduced wear on other components within the drive system. Additionally, the efficient operation of the idler pulley enhances the overall system efficiency, ensuring that the engine and its accessories perform at their best.

Installation Considerations

When installing the Cummins 3638640 Idler Pulley, it is important to follow guidelines and best practices to ensure proper fit and function. This includes verifying that the pulley is correctly aligned with the belt and other components, and that it is securely mounted. It is also recommended to inspect the belt for any signs of wear or damage before installation, and to ensure that the belt is properly tensioned after the pulley is installed. Following these steps will help to ensure that the pulley operates efficiently and reliably.

Troubleshooting Common Issues

Typical problems that may arise with idler pulleys include noise, vibration, or belt slippage. These issues can often be traced to improper installation, wear on the pulley or belt, or misalignment. Diagnostic steps may include inspecting the pulley and belt for signs of wear, checking the alignment of the pulley, and ensuring that the belt is properly tensioned. Solutions may involve replacing worn components, realigning the pulley, or adjusting the belt tension.

Maintenance Tips

Regular maintenance practices can help to prolong the life of the Cummins 3638640 Idler Pulley. This includes inspecting the pulley and belt at regular intervals for signs of wear or damage. Lubrication of the pulley’s bearing system, if applicable, can also help to reduce friction and wear 3. Signs that the pulley may need replacement include excessive noise, vibration, or visible wear on the pulley or belt. Following these maintenance tips will help to ensure the continued efficient operation of the drive system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a strong reputation in the automotive and heavy-duty truck industries for producing high-quality, reliable components. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of heavy-duty applications.

Idler Pulley Part 3638640 Compatibility with Cummins Engines

The Idler Pulley part 3638640, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the proper tension and alignment of the engine’s accessory belts, ensuring efficient operation and longevity of the engine components.

QSK45 CM500 and QSK60 CM500

The Idler Pulley part 3638640 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, which are known for their robust performance and reliability in various applications, including marine and industrial uses. The idler pulley ensures that the belts driving the engine’s accessories, such as the alternator and water pump, operate smoothly and without slippage.

QSK60 CM850 MCRS and QSK78 CM500

Similarly, the Idler Pulley part 3638640 is also compatible with the QSK60 CM850 MCRS and QSK78 CM500 engines. The QSK60 CM850 MCRS is a high-performance engine designed for demanding applications, while the QSK78 CM500 is another variant in the QSK series, offering a balance of power and efficiency. The idler pulley in these engines plays a vital role in maintaining the correct tension of the accessory belts, which is essential for the proper functioning of the engine’s ancillary systems.

In all these engines, the idler pulley is engineered to withstand the rigors of continuous operation, providing a reliable and durable solution for belt management. This ensures that the engine’s accessories receive the necessary power and support, contributing to the overall efficiency and performance of the engine.

Role of Part 3638640 Idler Pulley in Engine Systems

The idler pulley, specifically part 3638640, is an essential component in the operation of various engine systems, particularly those involving the fan drive mechanism.

In systems where the fan drive is employed, the idler pulley serves to maintain the proper tension of the belt that drives the fan. This is vital for ensuring that the fan operates efficiently, providing the necessary cooling for the engine. The idler pulley achieves this by adjusting its position, which in turn alters the tension on the belt.

Additionally, the idler pulley helps in reducing the wear and tear on the belt by ensuring it runs smoothly and does not slip. This is particularly important in high-stress environments where the engine operates under heavy load or in extreme temperatures.

Furthermore, the idler pulley plays a role in the overall stability of the engine’s accessory drive system. By keeping the belt properly aligned and tensioned, it contributes to the smooth operation of other components such as the alternator, water pump, and air conditioning compressor, all of which are interconnected through the belt drive system.

Conclusion

In summary, the Cummins 3638640 Idler Pulley is a critical component in maintaining the integrity and efficiency of the engine’s accessory drive system. Its role in ensuring proper belt tension and alignment is essential for the efficient operation of various engine components, contributing to the overall performance and reliability of heavy-duty trucks.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.