This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

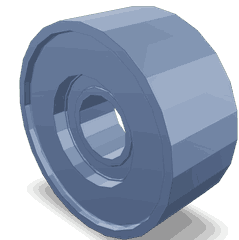

The Cummins 3967015 Idler Pulley is a critical component for commercial trucks, designed to enhance engine system efficiency and reliability. Understanding its function and significance is essential for maintaining vehicle performance and longevity.

Basic Concepts of Idler Pulleys

An idler pulley, such as the 3967015, is used in belt drive systems to guide and maintain tension in the belt. It ensures proper alignment and tension, facilitating efficient power transfer and reducing wear on the belt and driven components 1.

Purpose of the 3967015 Idler Pulley

This Cummins part is designed to maintain correct tension and alignment of belts within the engine system. It ensures efficient operation of engine accessories like the alternator, water pump, and air conditioning compressor, reducing the risk of slippage and wear 2.

Key Features

The 3967015 Idler Pulley is made from durable materials and features precision-machined surfaces and high-quality bearings. It may also have a specific groove pattern to enhance belt grip and reduce noise, contributing to its smooth operation and longevity 3.

Benefits of Using the 3967015 Idler Pulley

Using this part offers several advantages, including improved belt life, reduced noise during operation, and enhanced system efficiency. Proper belt tension ensures that engine accessories receive the necessary power without straining the engine 4.

Installation Considerations

Proper installation of the 3967015 Idler Pulley is crucial for optimal performance. Following manufacturer guidelines for torque specifications and alignment prevents issues like belt slippage or premature wear. Correct positioning and secure fastening are essential for efficient engine system operation 5.

Troubleshooting Common Issues

Common issues with idler pulleys include noise, wear, and misalignment. Noise may indicate a loose or worn pulley, while wear suggests the need for replacement. Misalignment can increase belt wear and reduce efficiency. Troubleshooting involves inspecting the pulley for damage, ensuring proper alignment and tension, and replacing it if necessary 6.

Maintenance Tips

Regular maintenance of the 3967015 Idler Pulley is important for continued performance. This includes periodic inspection for wear or damage, following lubrication requirements, and replacing the pulley when significant wear is observed to maintain engine system efficiency 7.

Compatibility and Application

The 3967015 Idler Pulley is designed for specific truck and engine models, ensuring compatibility with the intended engine systems. Understanding its application context is important for selecting the correct component for a given truck model 8.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its reliable and efficient engine and power generation products. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to enhance commercial truck performance and reliability 9.

Cummins Idler Pulley 3967015 Compatibility

The Cummins Idler Pulley part number 3967015 is compatible with several engine models, including the 6B5.9 and QSB5.9 44 CM550. This part is engineered to meet the rigorous demands of these engines, ensuring optimal performance and longevity 10.

Role of Part 3967015 Idler Pulley in Engine Systems

The 3967015 Idler Pulley is essential for maintaining the efficiency and reliability of engine systems. It guides and tensions the drive belt, ensuring smooth operation of connected components like the alternator, air conditioning compressor, and power steering pump 11.

Drive System Integration

In the drive system, the 3967015 Idler Pulley works with the drive belt to transfer power from the engine to auxiliary components. Proper belt tension ensures efficient power transfer and reduces wear on the belt and pulleys 12.

Water Pump Operation

The 3967015 Idler Pulley assists in the operation of the water pump by maintaining proper belt tension. This ensures the water pump runs efficiently, preventing overheating and potential engine damage 13.

Conclusion

The 3967015 Idler Pulley plays a vital role in the smooth and efficient operation of the drive system and cooling system. Its proper function is crucial for maintaining overall engine performance and reliability.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

General Information, Bulletin Number 3666231-02, Master Repair Manual.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

General Information, Bulletin Number 3666231-02, Master Repair Manual.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.