This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

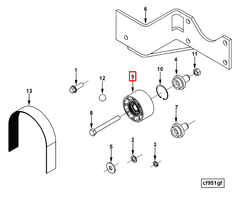

The 3979428 Idler Pulley, a component manufactured by Cummins, is designed for use in commercial trucks. It contributes to the efficient operation of the engine and accessory systems.

Basic Concepts of Idler Pulleys

An idler pulley maintains the proper tension and alignment of the belt within a belt-driven system. It supports the belt, ensuring it remains correctly positioned, which aids in the smooth transfer of power and reduces the likelihood of belt slippage or damage 1.

Role of the 3979428 Idler Pulley in Truck Operation

The 3979428 Idler Pulley interacts with various components of the engine and accessory systems. It maintains the correct tension on the belts that drive accessories such as the alternator, water pump, and air conditioning compressor, ensuring these components receive consistent power 2.

Key Features of the 3979428 Idler Pulley

This Cummins part is characterized by its robust design and construction. It is made from high-quality materials that offer durability and resistance to wear. The pulley’s design includes precision-machined surfaces and a high-quality bearing system, which allows for smooth operation and reduces friction 3.

Benefits of Using the 3979428 Idler Pulley

Utilizing this part in a truck’s engine system offers several advantages. It provides improved belt tension, which enhances the efficiency of power transfer to accessories. Additionally, by maintaining optimal belt alignment and tension, it reduces wear on both the belt and the driven components, contributing to enhanced overall system reliability and can lead to extended service intervals for maintenance.

Installation Considerations

Proper installation of the 3979428 Idler Pulley is important for ensuring its effective operation. Guidelines for installation include verifying alignment with other pulleys and components, adhering to specified torque values for fasteners, and ensuring compatibility with the truck’s existing parts. Following these best practices helps in achieving the desired performance and longevity of the pulley.

Troubleshooting Common Issues

Common issues associated with idler pulleys include noise, wear, and failure. Diagnostic steps for addressing these problems may involve inspecting the pulley for signs of damage or excessive wear, checking the belt for proper tension and alignment, and ensuring that the pulley’s bearing system is functioning correctly. Solutions may range from simple adjustments to replacement of worn components.

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and optimal performance of the 3979428 Idler Pulley. This includes periodic inspection for signs of wear or damage, ensuring the belt remains properly tensioned, and following lubrication guidelines for the pulley’s bearing system. Adhering to these maintenance tips can help in preventing unexpected failures and ensuring consistent operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Idler Pulley 3979428 Compatibility with Cummins Engines

The Idler Pulley part number 3979428, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part plays a role in the engine’s belt drive system, ensuring proper tension and alignment of the serpentine belt, which in turn drives essential components such as the alternator, water pump, and air conditioning compressor.

Compatible Engines

- 6C8.3

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

- L8.9

- L8.9 CM2670 L134C

- L9 CM2670 L128B

- QSC8.3 CM2880 C102

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2880)

Grouping of Compatible Engines

The Idler Pulley 3979428 is compatible with several engine models, which can be grouped based on their specifications and applications:

-

6C8.3, L8.9, L9 CM2670 L128B: These engines are typically found in smaller to medium-sized applications, such as construction equipment, agricultural machinery, and smaller commercial vehicles.

-

ISL9 CM2150 SN, ISL9.5 CM2880 L138, QSL9 CM850 (CM2880): These engines are part of the Cummins ISL and QSL series, which are known for their high performance and reliability in heavy-duty applications, including large trucks, buses, and industrial equipment.

-

L8.9 CM2670 L134C, QSC8.3 CM2880 C102, QSL8.9 CM2150 L141: These engines are part of the Cummins QSC and QSL series, designed for medium to heavy-duty applications, such as medium-duty trucks, buses, and various industrial machinery.

By ensuring the correct fitment of the Idler Pulley 3979428, users can maintain optimal engine performance and longevity, preventing potential issues related to belt slippage, misalignment, and component wear.

Role of Part 3979428 Idler Pulley in Engine Systems

The idler pulley, specifically part 3979428, is integral to the efficient operation of various engine systems. It is strategically positioned to interact with multiple components, ensuring smooth and reliable performance.

Interaction with Belt Tensioner Bracket

The idler pulley works in conjunction with the belt tensioner bracket to maintain the appropriate tension on the drive belt. This ensures that the belt remains securely in place and operates efficiently, reducing the risk of slippage or premature wear.

Support for Compressor and Refrigerant System

In systems where the compressor is driven by a belt, the idler pulley plays a significant role. It helps in maintaining the correct belt tension, which is essential for the compressor to function effectively. Proper tension ensures that the compressor can circulate refrigerant efficiently, maintaining the desired cooling performance within the system.

Enhancing Drive System Performance

The idler pulley is a key component in the drive system, assisting in the distribution of power from the engine to various accessories. By keeping the belt properly aligned and tensioned, it ensures that components such as the alternator, water pump, and power steering pump receive consistent power transmission. This results in enhanced overall performance and reliability of the drive system.

Contribution to Refrigerant Compressor Efficiency

Efficient operation of the refrigerant compressor is vital for maintaining optimal climate control within the vehicle. The idler pulley ensures that the belt driving the compressor is neither too tight nor too loose, which is essential for the compressor to operate within its designed parameters. This balance is crucial for the effective circulation of refrigerant, thereby ensuring the air conditioning system performs as expected.

Conclusion

In summary, the 3979428 Idler Pulley is a fundamental component that supports and enhances the functionality of various engine systems by ensuring proper belt tension and alignment. Its robust design, compatibility with a range of Cummins engines, and role in maintaining efficient operation make it a critical part of commercial truck engine systems.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series (2nd ed.). Springer.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.