This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

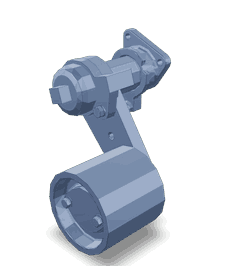

The Cummins 4975421 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the truck’s belt-driven systems, contributing to the efficient operation of various engine accessories. Understanding its role and significance can help in maintaining the overall performance and reliability of the vehicle.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt-driven systems to guide and maintain tension in the belt. It does not directly drive any component but plays a supportive role by ensuring the belt remains properly aligned and tensioned. This helps in the efficient transfer of power and reduces wear on both the belt and the driven components 1.

Purpose of the 4975421 Idler Pulley

The Cummins 4975421 Idler Pulley is integral to the operation of a truck’s accessory drive system. It maintains the correct tension and alignment of the belt, which is crucial for the efficient operation of components such as the alternator, water pump, and air conditioning compressor. By keeping the belt properly tensioned, it ensures these components receive consistent power, thereby enhancing the truck’s performance and reliability 2.

Key Features

The 4975421 Idler Pulley is constructed from high-quality materials, ensuring durability and long-term performance. Its design includes precision-machined surfaces and a robust bearing system, which contribute to smooth operation and reduced friction. Additionally, the pulley is engineered to withstand the harsh conditions typically encountered in commercial truck applications, providing reliable service over extended periods 3.

Benefits of Using the 4975421 Idler Pulley

Utilizing the Cummins 4975421 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment. This reduces the likelihood of belt slippage and premature wear. Furthermore, by ensuring consistent belt tension, it minimizes wear on other components within the drive system, leading to enhanced overall system efficiency and reliability.

Installation Considerations

When installing the 4975421 Idler Pulley, it is important to follow specific guidelines to ensure proper function. Preparatory steps include cleaning the installation area and inspecting the belt for any signs of damage. The necessary tools for installation typically include a socket wrench and alignment tools. Careful alignment checks should be performed to ensure the pulley is correctly positioned, which is vital for the efficient operation of the belt-driven system.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, wear, and belt misalignment. Noise can often be attributed to a worn bearing or improper alignment. Regular inspection and maintenance can help identify these issues early. Wear on the pulley or belt can be addressed by replacing the affected components. Belt misalignment may require re-alignment of the pulley or adjustment of the tensioner.

Maintenance Tips

To maintain the Cummins 4975421 Idler Pulley, regular inspections should be conducted to check for signs of wear or damage. Lubrication of the pulley’s bearing, if applicable, can help ensure smooth operation. Additionally, monitoring the belt tension and alignment will help prevent issues such as slippage or premature wear. Replacing the pulley when signs of significant wear are observed will help maintain the efficiency and reliability of the truck’s accessory drive system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation, providing reliable solutions for the commercial truck industry. Their product range includes a variety of components designed to enhance the performance and efficiency of commercial vehicles.

Idler Pulley Fitment for Cummins Engines

The Idler Pulley part number 4975421, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part plays a role in the engine’s belt drive system, ensuring the proper tension and alignment of the serpentine belt. Below is a detailed description of how this part fits with the specified engines.

QST30 CM2350 T101 and QST30 CM552

The Idler Pulley 4975421 is engineered to fit seamlessly with the QST30 CM2350 T101 and QST30 CM552 engines. These engines, while differing in their specific configurations and applications, share a common design that allows for the interchangeability of certain components, including the idler pulley.

In both engines, the idler pulley is positioned to guide and maintain the tension of the serpentine belt, which drives various engine accessories such as the alternator, water pump, and air conditioning compressor. The design of the idler pulley ensures that the belt remains properly aligned, reducing wear and tear on both the belt and the pulleys.

The fitment process involves aligning the idler pulley with the existing belt routing system. The pulley must be securely mounted to the engine block, typically using specific fasteners and mounting brackets designed for this purpose. Once installed, the idler pulley should be adjusted to ensure the correct belt tension, which is critical for the efficient operation of the engine’s accessories.

By ensuring that the idler pulley is correctly installed, engine performance and longevity are maintained, and the risk of belt-related failures is minimized. This compatibility underscores the importance of using genuine Cummins parts for maintenance and repairs, as they are specifically designed to meet the stringent requirements of Cummins engines.

Role of Part 4975421 Idler Pulley in Engine Systems

The 4975421 Idler Pulley is an integral component in maintaining the efficiency and reliability of various engine systems. Its primary function is to provide tension and support to the belts that drive essential engine accessories.

Interaction with the Drive System

In the drive system, the 4975421 Idler Pulley ensures that the belts remain taut, which is necessary for the efficient transfer of power from the engine to components such as the alternator, water pump, and air conditioning compressor. By maintaining proper belt tension, the Idler Pulley helps prevent slippage, which can lead to inefficient operation and increased wear on the belts and pulleys.

Contribution to the Fan System

Within the fan system, the 4975421 Idler Pulley plays a significant role in regulating the tension of the belt that drives the engine cooling fan. This ensures that the fan operates smoothly and effectively, which is vital for maintaining optimal engine temperature. Proper tension provided by the Idler Pulley prevents the belt from jumping off the pulleys or wearing out prematurely, thus ensuring consistent cooling performance and protecting the engine from overheating.

The 4975421 Idler Pulley, through its precise function in these systems, contributes to the overall durability and performance of the engine, making it a key component in the maintenance and operation of engine-driven accessories.

Conclusion

The Cummins 4975421 Idler Pulley is a critical component in the maintenance and operation of commercial truck engines. Its role in maintaining belt tension and alignment ensures the efficient operation of engine accessories, contributing to the overall performance and reliability of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.