This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

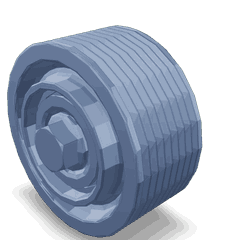

The Cummins 5265369 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s engine system, contributing to the efficient operation of the truck. Understanding its purpose and role is fundamental for maintaining the truck’s performance and longevity.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt-driven systems to maintain proper belt tension and alignment. It does not directly drive any component but instead supports the belt by guiding it and ensuring it remains properly tensioned and aligned. This is vital for the efficient transfer of power and the smooth operation of the system 4.

Purpose of the Cummins 5265369 Idler Pulley

The Cummins 5265369 Idler Pulley is integral to the engine’s accessory drive system in commercial trucks. It plays a role in maintaining the correct tension and alignment of the belts that drive various engine accessories, such as the alternator, water pump, and air conditioning compressor. By ensuring these belts operate under the right conditions, the idler pulley contributes to the overall efficiency and reliability of the engine system 2.

Key Features

The Cummins 5265369 Idler Pulley is constructed with specific design and material choices to enhance its performance and durability. It typically features a robust housing made from high-quality materials to withstand the demanding conditions within a truck engine. The pulley incorporates precision-engineered bearings that allow for smooth rotation and minimal friction. Additionally, unique design elements may be included to further improve its functionality and longevity in the harsh environment of a commercial truck engine 1.

Benefits

Utilizing the Cummins 5265369 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment. This reduces the likelihood of belt slippage or premature wear. Additionally, the design of the pulley helps in reducing noise and vibration within the engine compartment, leading to a smoother operation. Enhanced system efficiency is another benefit, as properly tensioned and aligned belts can transfer power more effectively, contributing to the overall performance of the truck 3.

Installation Considerations

When installing the Cummins 5265369 Idler Pulley, it is important to follow guidelines and best practices to ensure proper function. This includes aligning the pulley correctly within the engine’s accessory drive system and adhering to specified torque values for fastening components. Preparatory steps, such as cleaning the installation area and inspecting the belt for damage, are also crucial for a successful installation 3.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, wear, and misalignment. These issues can often be identified through visual inspection and listening for unusual sounds during engine operation. Diagnostic steps may involve checking the alignment of the pulley, inspecting the condition of the belt, and examining the bearings for signs of wear. Solutions can range from simple adjustments to replacement of worn components 2.

Maintenance Tips

Routine maintenance of the Cummins 5265369 Idler Pulley is key to ensuring its longevity and performance. This includes regular inspection intervals to check for signs of wear or damage, ensuring the pulley and its components are in good condition. Lubrication requirements should be followed as per the manufacturer’s guidelines to keep the bearings operating smoothly. Recognizing signs of wear, such as noise or vibration, can indicate the need for replacement or further inspection 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a commitment to quality, Cummins serves commercial truck markets with a diverse product range designed to meet the demanding requirements of heavy-duty applications. The company’s focus on quality and innovation is evident in its components, like the Cummins 5265369 Idler Pulley, which are engineered to deliver reliable performance in challenging environments 3.

Compatibility with Cummins Engines

The Idler Pulley part 5265369 by Cummins is designed to fit a variety of Cummins engine models. This part is essential for maintaining the proper tension of the engine’s serpentine belt, ensuring optimal performance and longevity of the engine components.

Engines with CM2350 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

These engines utilize the CM2350 series, and the Idler Pulley part 5265369 is compatible with both the B4.5 and ISB4.5 variants. The CM2350 series engines are known for their robust design and efficiency, making the idler pulley a crucial component for maintaining the belt’s tension and preventing slippage.

Engines with CM2620 Series

- D4.0 CM2620 D103B

- F3.8 CM2620 F120B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

The CM2620 series engines, including the D4.0, F3.8, and F4.5 variants, are also compatible with the Idler Pulley part 5265369. These engines are designed for high performance and reliability, and the idler pulley plays a vital role in ensuring the belt operates smoothly and efficiently.

Engines with CM2220 Series

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

The Idler Pulley part 5265369 is also suitable for the CM2220 series engines, which include the ISF2.8, ISF3.8, and ISF4.5 variants. These engines are engineered for durability and efficiency, and the idler pulley is essential for maintaining the correct belt tension.

Engines with CM2880 Series

- QSF2.8 CM2880 F114

- QSF3.8 CM2880 F112

Lastly, the Idler Pulley part 5265369 is compatible with the CM2880 series engines, including the QSF2.8 and QSF3.8 variants. These engines are designed for high performance and reliability, and the idler pulley ensures the belt operates smoothly and efficiently.

By ensuring the correct fitment of the Idler Pulley part 5265369, engine performance and longevity can be maintained, providing reliable operation across these various Cummins engine models 3.

Role in Engine Systems

The 5265369 Idler Pulley is an essential component in maintaining the efficiency and reliability of various engine systems. It plays a significant role in the proper functioning of the drive system, particularly in conjunction with the water pump and its drive mechanism.

In the drive system, the idler pulley ensures that the belt remains taut, which is vital for the transmission of power from the engine to the accessories it drives. Without adequate tension, the belt could slip, leading to inefficient power transfer and potential damage to the drive components.

When it comes to the water pump, the idler pulley assists in maintaining the correct alignment and tension of the belt that drives the pump. The water pump is responsible for circulating coolant through the engine to prevent overheating. A properly tensioned belt ensures that the water pump operates efficiently, providing consistent coolant flow.

Furthermore, the idler pulley’s role in the water pump drive system is to support the smooth operation of the belt. This support is essential for the longevity of the belt and the overall reliability of the cooling system. By keeping the belt properly aligned and tensioned, the idler pulley helps to reduce wear and tear on both the belt and the water pump, contributing to the engine’s stable performance and durability 4.

Conclusion

The Cummins 5265369 Idler Pulley is a critical component for maintaining the efficiency and reliability of commercial truck engines. Its role in ensuring proper belt tension and alignment is essential for the smooth operation of engine accessories and the overall performance of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩ ↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388786.

↩ ↩ ↩ ↩ ↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.