This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

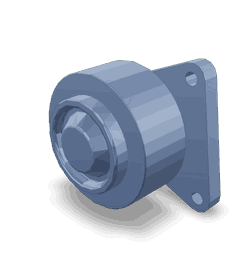

The Cummins 5301464 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the engine’s accessory drive system, contributing to the efficient operation of various engine components. Understanding its purpose and role is fundamental for maintaining the performance and reliability of commercial vehicles.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt drive systems to maintain proper belt tension and alignment. It does not directly drive any component but instead supports the belt by guiding it and ensuring it remains properly engaged with the driving and driven pulleys. This function is vital for the smooth and efficient transfer of power within the system, preventing belt slippage and reducing wear on both the belt and the pulleys it contacts 1.

Purpose of the 5301464 Idler Pulley

The Cummins 5301464 Idler Pulley plays a role in the engine’s accessory drive system by maintaining the correct tension and alignment of the belts that drive accessories such as the alternator, water pump, and air conditioning compressor. Its function ensures that these components receive consistent power transmission, which is crucial for their operation and, by extension, the overall performance of the truck 2.

Key Features

The 5301464 Idler Pulley is constructed from durable materials, designed to withstand the harsh conditions present in commercial truck environments. Its design includes precision-machined surfaces to ensure smooth belt operation and longevity. Additionally, it may feature unique characteristics such as a self-aligning bearing or a specific tensioning mechanism that enhances its performance and durability under varying operational loads 3.

Benefits of Using the 5301464 Idler Pulley

Utilizing the 5301464 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment, reducing the likelihood of belt failure. It also minimizes wear on other components within the accessory drive system, leading to enhanced overall system efficiency and reliability. Furthermore, its robust construction and design elements support long-term performance, even in demanding applications.

Installation Considerations

Proper installation of the 5301464 Idler Pulley is important for ensuring optimal performance and longevity. It is recommended to follow manufacturer guidelines closely, which may include specific torque settings for fasteners and alignment checks to ensure the pulley is correctly positioned within the belt drive system. Attention to these details helps prevent premature wear and ensures the pulley functions as intended.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, vibration, or belt slippage. These issues can often be traced back to improper installation, wear and tear, or misalignment. Diagnostic steps may involve inspecting the pulley and belt for signs of wear, checking the alignment of the pulley within the system, and ensuring all fasteners are properly tightened. Addressing these issues promptly can help maintain the efficiency and reliability of the accessory drive system.

Maintenance Tips

Routine maintenance practices are key to prolonging the life of the 5301464 Idler Pulley. Regular inspections should be conducted to check for signs of wear or damage, with particular attention to the belt’s condition and the pulley’s alignment. Lubrication guidelines, if applicable, should be followed to ensure smooth operation. Replacement criteria may include significant wear, damage, or if the pulley no longer maintains proper belt tension and alignment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. Its product offerings span a wide range of applications, providing reliable and efficient solutions for the transportation sector.

Idler Pulley 5301464 in Cummins Engines

The Idler Pulley 5301464, manufactured by Cummins, is a critical component in various Cummins engine models. This part plays a pivotal role in the engine’s belt-driven systems, ensuring the proper tension and alignment of the serpentine belt. The 5301464 Idler Pulley is designed to work seamlessly with several Cummins engine models, including but not limited to:

- QSB3.3 CM2250 EC

In these engines, the 5301464 Idler Pulley is strategically positioned to guide the serpentine belt, maintaining its path and tension. This ensures that the belt operates efficiently, driving essential components such as the alternator, water pump, and air conditioning compressor. The design and engineering of the 5301464 Idler Pulley are tailored to fit the specific needs of these engines, providing durability and reliability in various operating conditions.

The integration of the 5301464 Idler Pulley in these engines is a testament to Cummins’ commitment to quality and performance. By ensuring that the belt remains properly tensioned and aligned, this component helps maintain the overall efficiency and longevity of the engine’s ancillary systems.

Role of Part 5301464 Idler Pulley in Engine Systems

Part 5301464, the Idler Pulley, is integral to the efficient operation of various engine systems. It primarily interacts with the Drive Belt and Fan systems, ensuring smooth and reliable performance.

Interaction with the Drive Belt System

In the Drive Belt system, the Idler Pulley maintains proper tension on the belt. This tension is essential for the efficient transfer of power from the engine to other components such as the alternator, water pump, and air conditioning compressor. By keeping the belt taut, the Idler Pulley prevents slippage, which could lead to inefficient power transmission and potential damage to the belt or connected components.

Contribution to the Fan System

Within the Fan system, the Idler Pulley plays a significant role in regulating the fan belt’s tension. The fan belt drives the engine cooling fan, which is vital for dissipating heat from the engine. Proper tension ensures that the fan operates effectively, maintaining optimal engine temperature and preventing overheating. The Idler Pulley’s ability to adjust tension dynamically as the engine operates under varying loads contributes to the overall reliability and performance of the cooling system.

Conclusion

In summary, the Cummins 5301464 Idler Pulley is a key component in maintaining the integrity and efficiency of the Drive Belt and Fan systems, ensuring that these systems operate seamlessly within the engine environment. Its robust design, precise engineering, and strategic placement in Cummins engines underscore its importance in the reliable operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.