This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

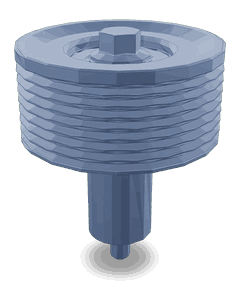

The Cummins 5342505 Idler Pulley is a component used in the belt drive systems of commercial trucks. This article provides an overview of the idler pulley’s function, its role in truck operations, key features, benefits, and maintenance suggestions.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley that does not drive a machine part or attachment. Instead, it is used to guide or tension a belt in a belt drive system. Idler pulleys help maintain proper belt tension and alignment, ensuring efficient power transmission and reducing wear on both the belt and the driven components 1.

Function and Role of the 5342505 Idler Pulley

The 5342505 Idler Pulley by Cummins is designed to maintain the correct tension and alignment of belts in the engine’s accessory drive system. This ensures that components such as the alternator, water pump, and air conditioning compressor operate efficiently. The idler pulley helps in distributing the load evenly across the belt, which prolongs the belt’s lifespan and enhances the overall performance of the truck’s engine accessories 2.

Key Features

- Constructed from durable materials to withstand high stress and temperatures.

- Designed for precise fit and easy installation.

- Features a smooth bearing surface to reduce friction and wear.

- Engineered to meet or exceed OEM specifications for reliability and performance.

Benefits

- Enhances the efficiency of the belt drive system by maintaining proper tension and alignment.

- Reduces the risk of belt slippage and associated downtime.

- Contributes to the longevity of belts and driven components by ensuring even load distribution.

- Designed to operate quietly, minimizing noise in the engine compartment.

Troubleshooting and Maintenance

Regular inspection of the idler pulley is recommended to ensure it is functioning correctly. Signs of wear or damage, such as excessive noise, visible wear on the pulley surface, or improper belt tension, should be addressed promptly. Maintenance tasks may include lubricating the pulley bearings, adjusting belt tension, or replacing the pulley if necessary. Following the manufacturer’s maintenance schedule can help prevent unexpected failures and ensure optimal performance 3.

Compatibility with Cummins Engines

The Idler Pulley 5342505, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is integral to the engine’s operation, ensuring the proper tension and alignment of the engine’s belt system. Below is a detailed compatibility overview of this idler pulley with specific Cummins engine models.

Compatible Engines

- F3.8 CM2350 F107

- F4.5 CM2620 F141C

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

Grouping by Engine Configuration

The engines listed can be grouped based on their configurations and compatibility with the 5342505 idler pulley:

-

F3.8 CM2350 F107 and QSF3.8 CM2350 F107

- Both engines share the same base model, CM2350, and are equipped with the F107 configuration. The 5342505 idler pulley is specifically designed to fit these engines, ensuring optimal performance and longevity.

-

F4.5 CM2620 F141C

- This engine, with the CM2620 model and F141C configuration, is also compatible with the 5342505 idler pulley. Despite differences in engine size and power output, the pulley’s design accommodates the unique requirements of this engine.

-

QSF3.8 CM2880 F112

- The QSF3.8 CM2880 F112 engine, while slightly different in model number, is also compatible with the 5342505 idler pulley. This compatibility is due to the shared design principles and engineering standards that ensure the pulley fits seamlessly into the engine’s belt system.

Each of these engines relies on the 5342505 idler pulley to maintain the correct tension and alignment of the engine’s belt, ensuring smooth operation and reducing wear on other components.

Role of Part 5342505 Idler Pulley in Engine Systems

The 5342505 Idler Pulley is a component in maintaining the efficiency and reliability of various engine systems. It is particularly significant in the context of the drive mechanism, water pump, and water pump drive.

Drive Mechanism

In the drive mechanism, the 5342505 Idler Pulley facilitates the smooth operation of the belt-driven accessories. By altering the belt’s path, it ensures that the belt remains taut and properly aligned. This tension is vital for the efficient transfer of power from the engine to accessories such as the alternator, power steering pump, and air conditioning compressor. The idler pulley reduces belt slippage and wear, contributing to the longevity and performance of the drive system.

Water Pump

The water pump is a key component in the engine’s cooling system, responsible for circulating coolant through the engine block and radiator. The 5342505 Idler Pulley plays a supportive role by maintaining the correct tension on the belt that drives the water pump. Proper belt tension is necessary for the water pump to operate efficiently, ensuring consistent coolant flow and effective engine temperature management. This, in turn, prevents overheating and potential engine damage.

Water Pump Drive

In the water pump drive system, the 5342505 Idler Pulley ensures that the belt driving the water pump remains in optimal condition. It helps in adjusting the belt’s position to accommodate wear and tear, thereby prolonging the belt’s lifespan. Additionally, the idler pulley minimizes noise and vibration within the drive system, leading to a smoother and more reliable operation of the water pump. This results in enhanced cooling performance and overall engine stability.

Conclusion

The Cummins 5342505 Idler Pulley is a critical component in the belt drive systems of commercial trucks, ensuring the efficient operation of engine accessories and the cooling system. Its durable construction, precise fit, and smooth bearing surface contribute to the longevity and performance of the truck’s engine. Regular maintenance and prompt attention to signs of wear are essential to prevent unexpected failures and ensure optimal performance.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Osgood, Libby, Gayla Cameron, and Emma Christensen. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.