This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

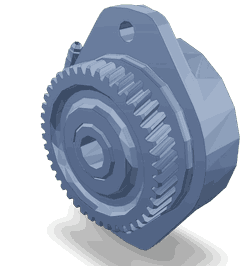

The Hydraulic Pump Drive 3936232, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces this hydraulic pump drive to enhance the functionality and efficiency of truck hydraulic systems. This component is integral to the operation of various hydraulic functions within commercial trucks, contributing to their overall performance and reliability.

Basic Concepts of Hydraulic Pump Drives

Hydraulic systems utilize fluid power to perform mechanical tasks. At the heart of these systems are hydraulic pumps, which convert mechanical energy into hydraulic energy by pressurizing a fluid. This pressurized fluid then powers hydraulic actuators, which perform work. Hydraulic pump drives, like the 3936232, are mechanisms that connect the hydraulic pump to the engine or another power source, ensuring efficient transfer of power and operation of the hydraulic system 1.

Purpose of the Hydraulic Pump Drive 3936232

The Hydraulic Pump Drive 3936232 plays a role in the operation of a truck by facilitating the connection between the hydraulic pump and the engine. Its applications include powering hydraulic systems that operate brakes, steering mechanisms, and other hydraulically actuated components within the truck. This drive ensures that the hydraulic pump receives the necessary power to function correctly, thereby supporting the truck’s hydraulic operations.

Key Features

The Hydraulic Pump Drive 3936232 is characterized by its robust design, which incorporates high-quality materials to ensure durability and reliability. It features advanced technological elements that enhance its performance, including precision engineering for optimal power transfer and efficiency. The design also considers ease of installation and integration within existing truck hydraulic systems.

Benefits

The advantages of the Hydraulic Pump Drive 3936232 include improved efficiency in power transfer, which contributes to the overall performance of the truck’s hydraulic system. Its reliable operation reduces the likelihood of system failures, enhancing the truck’s operational reliability. Additionally, the drive’s design contributes to better fuel efficiency by ensuring that the hydraulic pump operates at optimal levels, reducing unnecessary energy consumption 2.

Installation and Integration

Proper installation of the Hydraulic Pump Drive 3936232 involves aligning it with the hydraulic pump and the engine’s power output. It is important to follow manufacturer guidelines to ensure secure and efficient integration. This process may require adjustments to existing components to accommodate the drive, ensuring a seamless connection that supports the hydraulic system’s operation.

Operational Efficiency

The Hydraulic Pump Drive 3936232 contributes to the overall efficiency of truck operations by ensuring that the hydraulic pump receives consistent and adequate power. This efficiency translates into better performance of hydraulically actuated systems, potentially leading to reduced fuel consumption and lower maintenance requirements. Its role in maintaining system efficiency is vital for the smooth operation of commercial trucks.

Troubleshooting Common Issues

Common issues with hydraulic pump drives may include power transfer inefficiencies or mechanical wear. Troubleshooting steps involve checking the alignment and connection of the drive with the hydraulic pump and engine, inspecting for wear or damage, and ensuring that all components are securely fastened. Regular maintenance and inspections can help identify and address potential issues before they lead to system failures.

Maintenance Practices

To ensure the longevity and optimal performance of the Hydraulic Pump Drive 3936232, it is recommended to follow a routine maintenance schedule. This includes regular inspections for wear and damage, cleaning components to remove debris, and lubricating moving parts as necessary. Adhering to manufacturer guidelines for maintenance can help prevent unexpected failures and extend the lifespan of the drive.

Safety Considerations

When working with hydraulic systems and the Hydraulic Pump Drive 3936232, it is important to observe safety practices. This includes wearing appropriate personal protective equipment, ensuring that the system is depressurized before performing maintenance, and following all manufacturer safety guidelines. Understanding the risks associated with hydraulic systems, such as high-pressure fluid and moving parts, is crucial for safe operation and maintenance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s product range includes engines, powertrains, and related components, demonstrating its expertise in the automotive industry and its dedication to advancing technology and efficiency in power solutions.

Compatibility with Cummins Engines

The Hydraulic Pump Drive part 3936232, manufactured by Cummins, is designed to be compatible with a variety of Cummins engines. This part is integral in ensuring the proper functioning of the hydraulic systems in these engines. Below is a detailed look at the engines with which this hydraulic pump drive is compatible:

ISC CM554 and ISL CM554 Engines

The Hydraulic Pump Drive part 3936232 fits seamlessly with the ISC CM554 and ISL CM554 engines. These engines are known for their robust performance and are commonly used in heavy-duty applications. The compatibility ensures that the hydraulic systems in these engines operate efficiently, providing the necessary power and reliability.

QSC8.3 CM554 and QSC8.3 CM850 (CM2850) Engines

This hydraulic pump drive is also compatible with the QSC8.3 CM554 and QSC8.3 CM850 (CM2850) engines. These engines are designed for a range of applications, from construction to agricultural use, and the hydraulic pump drive ensures that the hydraulic systems function optimally, enhancing the overall performance of the engines.

QSC9 CM2250/QSL9 CM2250 Engines

The Hydraulic Pump Drive part 3936232 is suitable for the QSC9 CM2250 and QSL9 CM2250 engines. These engines are engineered for high-performance applications, and the hydraulic pump drive plays a crucial role in maintaining the efficiency and reliability of the hydraulic systems.

QSL8.9 CM2150 L141 Engine

This part is also compatible with the QSL8.9 CM2150 L141 engine. This engine is designed for specific applications requiring high power and efficiency, and the hydraulic pump drive ensures that the hydraulic systems perform as expected.

QSL9 CM2250, QSL9 CM2350 L102, and QSL9 CM554 Engines

The Hydraulic Pump Drive part 3936232 fits the QSL9 CM2250, QSL9 CM2350 L102, and QSL9 CM554 engines. These engines are used in various demanding applications, and the hydraulic pump drive is essential for the proper functioning of their hydraulic systems.

QSL9 CM850 (CM2850) Engine

Lastly, the Hydraulic Pump Drive part 3936232 is compatible with the QSL9 CM850 (CM2850) engine. This engine is designed for applications that require high performance and reliability, and the hydraulic pump drive ensures that the hydraulic systems operate smoothly and efficiently.

Role of Part 3936232 Hydraulic Pump Drive in Engine Systems

The hydraulic pump drive, identified by part number 3936232, is a component in the operation of various engine systems. Its primary function is to transfer mechanical energy from the engine to the hydraulic pump, enabling the pump to generate hydraulic pressure. This pressure is then utilized to power various hydraulic systems within the engine.

Integration with the Drive System

The hydraulic pump drive is directly connected to the engine’s drive system. This connection ensures that as the engine operates, rotational energy is efficiently transmitted to the hydraulic pump. The drive system typically includes a series of gears and shafts that work in unison to maintain consistent power delivery. The hydraulic pump drive acts as a link in this chain, ensuring that the hydraulic pump receives the necessary power to function effectively.

Interaction with the Front Gear Train Accessory

The front gear train accessory plays a significant role in the distribution of power within the engine. The hydraulic pump drive interfaces with this accessory to ensure that the hydraulic pump receives a steady supply of mechanical energy. The front gear train accessory often includes a series of gears that mesh together to transfer power from the engine to various accessories, including the hydraulic pump. The hydraulic pump drive must be precisely aligned with these gears to maintain efficient operation and prevent energy loss.

Mounting Considerations

Proper mounting of the hydraulic pump drive is essential for its effective operation. The drive must be securely mounted to the engine block or another stable structure to ensure that it can withstand the forces generated during operation. This mounting not only provides stability but also helps in aligning the drive with the front gear train accessory and the hydraulic pump. Any misalignment can lead to inefficient power transfer and potential damage to the components.

Conclusion

In summary, the hydraulic pump drive (part 3936232) is a component that ensures the hydraulic pump receives the necessary mechanical energy to generate hydraulic pressure. Its integration with the drive system, interaction with the front gear train accessory, and proper mounting are all aspects that contribute to the efficient operation of the engine’s hydraulic systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.