This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

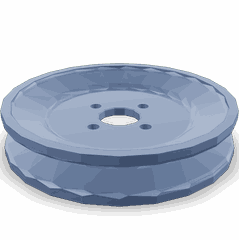

The Cummins Sea Water Pump Pulley (Part #4943126) is a component designed for use in commercial trucks, particularly those equipped with marine or industrial engines. This pulley is integral to the operation of the sea water pump, which is responsible for circulating coolant through the engine to maintain optimal operating temperatures.

Basic Concepts

Sea water pump pulleys operate on fundamental mechanical principles. They are driven by the engine’s crankshaft via a belt, which in turn powers the sea water pump. The pump circulates coolant—typically seawater in marine applications—through the engine’s cooling system. This circulation helps dissipate heat generated by the engine, ensuring it operates within safe temperature ranges 1.

Purpose and Function

This Cummins part plays a role in the engine cooling system by facilitating the operation of the sea water pump. By transferring rotational force from the engine’s crankshaft to the pump, it enables the pump to circulate coolant. This circulation is vital for dissipating heat, thereby helping to maintain the engine’s temperature within optimal ranges for efficient and reliable operation 2.

Key Features

The Sea Water Pump Pulley is constructed with materials and design elements that enhance its performance and durability. It is typically made from high-strength materials to withstand the rigors of continuous operation in demanding environments. Design features may include precision machining for smooth operation, corrosion-resistant coatings for longevity in marine environments, and a robust construction to handle the stresses of belt-driven applications 3.

Benefits

Using this part can contribute to improved engine efficiency, reliability, and longevity. Its precise engineering and durable construction help ensure consistent performance, reducing the likelihood of cooling system failures. This reliability is particularly important in commercial applications where downtime can be costly.

Installation and Compatibility

Proper installation of the Sea Water Pump Pulley is important for ensuring its effective operation and compatibility with the engine. Installation procedures may vary depending on the specific engine model, so it is important to follow manufacturer guidelines. Ensuring the pulley is correctly aligned and securely fastened will help prevent issues such as belt slippage or pump malfunction.

Maintenance and Troubleshooting

Routine maintenance of the Sea Water Pump Pulley involves checking for signs of wear or damage, ensuring the belt is in good condition and properly tensioned, and verifying that the pulley and pump operate smoothly without unusual noises. Troubleshooting common issues may involve inspecting for belt wear, checking alignment, and ensuring there are no obstructions in the cooling system that could impede coolant flow.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a reputation for quality and reliability, Cummins has been a trusted name in the industry for many years. The company’s commitment to innovation and customer satisfaction is reflected in its wide range of automotive components, including the Sea Water Pump Pulley.

Sea Water Pump Pulley (Part 4943126) Compatibility with Cummins Engines

The Sea Water Pump Pulley, identified by the part number 4943126, is a component designed to interface with the sea water pump in marine applications. This pulley is engineered to ensure efficient and reliable operation of the sea water pump, which is essential for cooling and lubrication systems in marine engines.

Compatibility with Cummins Marine Engines

The Sea Water Pump Pulley (4943126) is specifically designed to fit the following Cummins marine engines:

- QSB5.9 CM850

- QSB6.7 M CM2250

These engines are part of Cummins’ range of marine power systems, known for their robust performance and reliability in demanding marine environments. The pulley is engineered to work seamlessly with the sea water pump in these engines, ensuring optimal performance and longevity.

The compatibility of the Sea Water Pump Pulley with these engines is crucial for maintaining the efficiency of the cooling and lubrication systems. Proper installation and maintenance of this component are essential to prevent any disruptions in the engine’s operation, which could lead to overheating and potential damage.

By ensuring that the Sea Water Pump Pulley is correctly fitted and maintained, operators can rely on the consistent performance of their Cummins marine engines, even in the most challenging marine conditions.

Understanding the Integration of Part 4943126 Sea Water Pump Pulley in Engine Systems

This part is an integral component in the operation of marine engine systems, specifically within the raw water and sea water pump assemblies. This pulley facilitates the transfer of mechanical energy from the engine to the pump, ensuring efficient and reliable operation of the cooling system.

Role in Raw Water Pump Systems

In raw water pump systems, the 4943126 pulley is connected to the engine’s crankshaft via a belt. As the engine runs, the crankshaft’s rotation is transmitted to the pulley, which in turn drives the raw water pump. This pump draws in raw water from the surrounding environment, which is then circulated through the engine’s cooling passages. The consistent rotation provided by the pulley ensures a steady flow of water, maintaining optimal engine temperature and preventing overheating.

Function in Sea Water Pump Assemblies

Within sea water pump assemblies, the 4943126 pulley plays a similar yet specialized role. The sea water pump is often used in more complex marine engine systems where the raw water is further filtered or treated before being used for cooling. The pulley’s reliable operation is essential for driving the sea water pump, which handles the additional tasks of filtration and sometimes pressurization. This ensures that the water reaching the engine’s cooling system is clean and at the correct pressure, enhancing the efficiency and longevity of the engine.

Ensuring System Harmony

The integration of the 4943126 pulley within these systems requires precise alignment and maintenance. Proper belt tension and pulley alignment are necessary to avoid slippage and ensure efficient power transfer. Regular inspection and maintenance of the pulley and associated components are recommended to prevent failures and ensure the continuous, reliable operation of the engine’s cooling system 4.

Conclusion

The Cummins Sea Water Pump Pulley (Part #4943126) is a critical component in the cooling systems of marine and industrial engines. Its role in facilitating the operation of the sea water pump ensures efficient heat dissipation and maintains optimal engine temperatures. The pulley’s durable construction, precise engineering, and compatibility with specific Cummins marine engines make it a reliable choice for maintaining engine efficiency and reliability in demanding environments.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.