This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

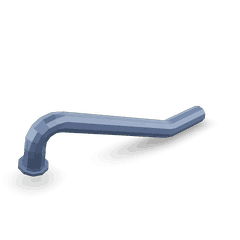

The Sea Water Pump Tube, identified by Part #5267061, is a component manufactured by Cummins, a well-established name in the automotive and industrial sectors. This tube is integral to the cooling systems of heavy-duty truck engines, particularly those operating in marine environments. Its role is to facilitate the circulation of sea water, which aids in regulating engine temperature and ensuring optimal performance under demanding conditions.

Function and Operation

The Sea Water Pump Tube operates within the engine cooling system by channeling sea water from the surrounding environment into the engine’s cooling passages. This process helps dissipate heat generated during engine operation, maintaining the engine within its optimal temperature range. The tube is connected to the sea water pump, which draws in sea water and propels it through the tube and into the engine’s cooling system. The efficient circulation of sea water is vital for preventing overheating and ensuring the longevity of engine components 1.

Key Features

The Sea Water Pump Tube is designed with several features that enhance its performance and durability. It is typically constructed from corrosion-resistant materials to withstand the harsh marine environment. The tube’s dimensions are engineered to ensure a proper fit within the engine’s cooling system, facilitating efficient water flow. Additionally, the tube may incorporate unique characteristics such as reinforced sections to resist wear and tear, and smooth internal surfaces to minimize flow resistance 2.

Benefits

The Sea Water Pump Tube offers several advantages. Its efficient design contributes to improved engine cooling, which is crucial for maintaining engine performance and longevity. The tube’s durable construction ensures it can withstand the corrosive effects of sea water, making it suitable for marine applications. Furthermore, its compatibility with Cummins engines ensures seamless integration and reliable operation 3.

Installation and Maintenance

Proper installation of the Sea Water Pump Tube is crucial for ensuring optimal performance. It should be securely fitted within the engine’s cooling system, with all connections tight to prevent leaks. Regular maintenance procedures include inspecting the tube for signs of wear or corrosion, and replacing it if necessary to maintain efficient cooling. Troubleshooting common issues may involve checking for blockages within the tube or ensuring the sea water pump is functioning correctly.

Common Applications

The Sea Water Pump Tube is commonly utilized in environments where engines are exposed to sea water, such as marine applications and offshore operations. It is also relevant for heavy-duty trucking in coastal regions, where engines may be subjected to salty air and occasional exposure to sea water. Its robust design makes it suitable for these challenging environments.

Safety Considerations

When working with the Sea Water Pump Tube, it is important to follow safety precautions to mitigate risks. This includes proper handling to avoid damage to the tube, secure storage to prevent corrosion, and safe disposal procedures to minimize environmental impact. Ensuring the tube is correctly installed and maintained will also contribute to safe operation of the engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and industrial sectors. The company offers a wide range of products designed to meet the needs of various applications, from on-highway transportation to off-highway construction and power generation.

Sea Water Pump Tube (Part 5267061) in Cummins Engines

The Sea Water Pump Tube, identified by the part number 5267061, is a critical component in the cooling systems of several Cummins marine engines. This part is essential for the proper operation of the engine’s cooling system, ensuring that the engine maintains optimal operating temperatures by facilitating the flow of sea water through the engine.

Application in Cummins Marine Engines

The Sea Water Pump Tube is compatible with a range of Cummins marine engines, including:

- QSC8.3 CM850 (CM2850)

This part is designed to fit seamlessly into the cooling system architecture of these engines, providing a reliable conduit for sea water to flow through the engine’s heat exchangers and other cooling components. The integration of the Sea Water Pump Tube is crucial for maintaining the efficiency and longevity of the engine by preventing overheating and ensuring consistent performance in marine environments.

Importance of the Sea Water Pump Tube

The Sea Water Pump Tube is a vital part of the engine’s cooling system, and its proper installation and maintenance are essential for the engine’s overall health. The tube’s design ensures that it can withstand the harsh conditions of marine environments, including exposure to saltwater, which can be corrosive and abrasive. The use of high-quality materials in the construction of this part ensures durability and reliability, contributing to the engine’s performance and lifespan.

Compatibility and Installation

When installing the Sea Water Pump Tube in Cummins marine engines, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. The tube must be correctly aligned and securely attached to the engine’s cooling system components to prevent leaks and ensure efficient sea water flow. Regular inspection and maintenance of the Sea Water Pump Tube are recommended to detect any signs of wear or damage, which can be addressed promptly to avoid potential engine issues.

Role of Part 5267061 Sea Water Pump Tube in Engine Systems

This Cummins part is an essential component in marine engine systems, facilitating the circulation of sea water to various parts of the engine for cooling purposes.

Integration with the Cooler

In marine engine systems, the cooler is a vital component designed to maintain optimal operating temperatures. The Sea Water Pump Tube plays a significant role here by directing sea water into the cooler. As the engine operates, it generates considerable heat. The Sea Water Pump Tube ensures a steady flow of sea water into the cooler, where the water absorbs the heat from the engine’s coolant. This process effectively reduces the temperature of the coolant, which then circulates back to the engine to absorb more heat. The continuous cycle ensures that the engine remains within safe operating temperatures, enhancing performance and longevity.

Interaction with Marine Gear Oil

Marine gear oil is specifically formulated to lubricate and protect the gears within the marine transmission system. The Sea Water Pump Tube indirectly supports the efficiency of the marine gear oil by maintaining the overall temperature of the engine system. When the engine is cooled efficiently by the Sea Water Pump Tube, the thermal stress on the gear oil is reduced. This allows the marine gear oil to perform its lubricating functions more effectively, minimizing wear and tear on the gears. Consequently, the longevity and reliability of the marine transmission system are enhanced.

Conclusion

In summary, the Sea Water Pump Tube (Part 5267061) is integral to the efficient operation of marine engine systems. By ensuring proper cooling through the cooler and indirectly supporting the performance of marine gear oil, it contributes significantly to the overall reliability and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.