This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

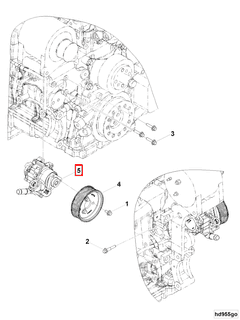

The Cummins 5295272 Hydraulic Pump is a specialized component designed for use in commercial truck operations. Its purpose is to facilitate the hydraulic systems that are integral to the functionality of various truck systems. This part is significant in ensuring the efficient operation of hydraulic-driven mechanisms within commercial trucks.

Basic Concepts of Hydraulic Pumps

Hydraulic systems operate on the principle of fluid power, where mechanical energy is converted into hydraulic energy. Hydraulic pumps play a key role in this process by generating the flow of hydraulic fluid, which is then used to power actuators and other components. These pumps work by drawing in fluid and pressurizing it, which allows for the transfer of power through hydraulic lines to various parts of the system 1.

Purpose of the Cummins 5295272 Hydraulic Pump

This Cummins part is specifically designed to serve various functions within commercial trucks. It is utilized in systems that require hydraulic power, such as braking systems, steering mechanisms, and suspension systems. The pump ensures that these systems operate smoothly and efficiently by providing the necessary hydraulic pressure and flow.

Key Features

The Cummins 5295272 Hydraulic Pump is characterized by its robust design and construction. It is built using high-quality materials that enhance its durability and performance. The pump’s design includes features that improve its efficiency and reliability, ensuring it can withstand the demanding conditions of commercial truck operations.

Benefits of Using the Cummins 5295272 Hydraulic Pump

Operators of commercial trucks can experience several advantages by using this part. These include improved system efficiency, increased reliability, and potential cost savings due to reduced maintenance requirements and longer operational life. The pump’s design also contributes to enhanced performance of the truck’s hydraulic systems.

Installation and Integration

Proper installation of the Cummins 5295272 Hydraulic Pump is vital for its effective operation within a truck’s hydraulic system. This process involves ensuring that the pump is correctly aligned and securely mounted, as well as verifying that all hydraulic lines and connections are properly installed. Careful consideration should be given to the pump’s integration with existing systems to ensure compatibility and optimal performance 2.

Maintenance and Troubleshooting

Routine maintenance is essential for the longevity and performance of the Cummins 5295272 Hydraulic Pump. This includes regular checks for leaks, monitoring fluid levels, and ensuring that the pump and its components are free from contaminants. Troubleshooting common issues may involve inspecting for worn parts, checking hydraulic fluid quality, and addressing any unusual noises or performance drops 3.

Performance and Efficiency

The Cummins 5295272 Hydraulic Pump is designed to deliver high performance and efficiency. Its flow rates and pressure capabilities are tailored to meet the demands of commercial truck applications. The pump’s energy consumption is optimized to provide efficient operation, contributing to the overall efficiency of the truck’s hydraulic systems.

Safety Considerations

When working with the Cummins 5295272 Hydraulic Pump, it is important to observe safety guidelines to protect operators and maintenance personnel. This includes ensuring that the pump is properly secured during operation, using appropriate personal protective equipment, and following manufacturer recommendations for maintenance and operation.

Environmental Impact

Cummins is committed to minimizing the environmental impact of its products. The Cummins 5295272 Hydraulic Pump is designed with eco-friendly features and practices in mind, such as efficient energy use and the use of environmentally responsible materials. Cummins continues to explore ways to further reduce the environmental footprint of its hydraulic pumps.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive experience in manufacturing commercial truck components underscores its position as a trusted provider of reliable and high-performance parts.

Compatibility with Cummins Engines

This part is designed to integrate seamlessly with a variety of Cummins engines. It is engineered to provide reliable hydraulic power, ensuring optimal performance across different engine models.

F2.8 CM2620 F135B and ISF2.8 CM2220 F129

The Hydraulic Pump 5295272 is compatible with the F2.8 CM2620 F135B and ISF2.8 CM2220 F129 engines. These engines are known for their robust design and efficiency, making them suitable for heavy-duty applications. The pump’s integration with these engines ensures that the hydraulic systems operate smoothly, providing the necessary power for various functions.

QSF2.8 CM2880 F104, F108, and F114

The Hydraulic Pump 5295272 also fits the QSF2.8 CM2880 F104, F108, and F114 engines. These engines are part of the Cummins QSF series, which is recognized for its versatility and reliability in demanding environments. The pump’s design allows it to work efficiently with these engines, ensuring that the hydraulic systems maintain their performance under various operating conditions.

The compatibility of the Hydraulic Pump 5295272 with these engines is a testament to Cummins’ commitment to providing high-quality components that enhance the functionality and reliability of their engines.

Role of Part 5295272 Hydraulic Pump in Engine Systems

The hydraulic pump, specifically part 5295272, is an integral component within various engine systems, facilitating the efficient operation of numerous auxiliary systems. Its primary function is to generate the hydraulic pressure necessary for the operation of these systems.

Integration with Auxiliary Systems

-

Steering Systems: The hydraulic pump provides the necessary pressure to power the hydraulic steering systems. This allows for smoother and more responsive steering, especially under varying load conditions.

-

Braking Systems: In systems where hydraulic brakes are employed, the pump ensures consistent pressure is maintained, contributing to reliable braking performance. This is particularly important in heavy-duty applications where brake systems are subjected to significant stress.

-

Suspension Systems: Many advanced suspension systems rely on hydraulic components to adjust ride height and damping characteristics. The hydraulic pump ensures these systems receive the required pressure to function correctly, enhancing vehicle stability and comfort.

-

Transmission Systems: Certain automatic transmissions use hydraulic systems to manage gear shifts. The hydraulic pump plays a key role in providing the necessary pressure to ensure smooth and precise gear changes.

-

Power Take-Off (PTO) Systems: In applications where PTO systems are used, such as agricultural or construction equipment, the hydraulic pump is essential for powering hydraulic motors and other auxiliary equipment.

Operational Synergy

The hydraulic pump works in concert with various sensors and control units to maintain optimal pressure levels. This ensures that all connected systems receive the appropriate amount of hydraulic fluid, preventing issues such as system failure or reduced performance.

Conclusion

In summary, the Cummins 5295272 Hydraulic Pump is a foundational component that enhances the functionality and reliability of multiple auxiliary systems within engine applications. Its role in generating and maintaining hydraulic pressure is essential for the seamless operation of these systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.