This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

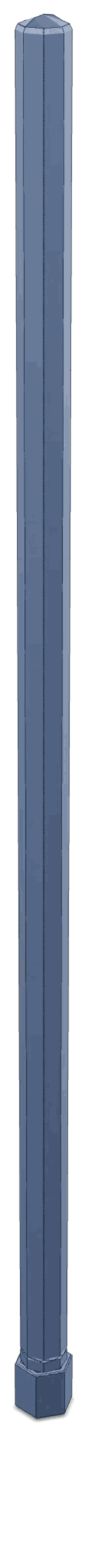

The Cummins 3041013 Push Rod is a critical component in heavy-duty truck engines, specifically designed for the overhead valve (OHV) engine configuration. This part facilitates the transfer of motion from the camshaft to the valves, ensuring precise timing for the intake and exhaust of gases, which is essential for engine performance and efficiency 1.

Basic Concepts of Push Rods

Push rods are integral to OHV engines, converting the rotational motion of the camshaft into linear motion that operates the valves. This mechanism is crucial for maintaining the precise timing of valve operations, directly impacting engine performance and efficiency 2.

Purpose of the Cummins 3041013 Push Rod

This Cummins part is designed to transmit motion from the camshaft to the valves, working in conjunction with the camshaft and rocker arms. Its primary function is to ensure that the valves open and close in sync with the engine’s operation, contributing to the engine’s overall performance and reliability 3.

Key Features

The 3041013 is constructed from high-quality materials, offering resistance to wear and fatigue. Its design includes precise dimensions and tolerances for smooth operation. Additionally, it may feature specific coatings or treatments to reduce friction and enhance longevity.

Benefits

Using the 3041013 offers several advantages, including improved engine efficiency through precise valve timing, enhanced engine reliability due to its robust construction, and potential improvements in overall engine performance, such as smoother operation and increased power output.

Installation and Compatibility

Proper installation of this part is crucial for optimal engine performance. It’s important to follow manufacturer guidelines and verify compatibility with the specific engine model to ensure it meets the necessary specifications.

Maintenance and Troubleshooting

Regular inspection and care are essential for maintaining the 3041013. Checking for signs of wear or damage and troubleshooting common issues by examining the push rod for proper fit and function within the engine are key maintenance practices.

Cummins Overview

Cummins Inc. is renowned for its high-quality components for heavy-duty trucks. The company’s commitment to manufacturing excellence is reflected in its wide range of products, designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Specific Engines

V903 and VTA903 Engines

The 3041013 is crucial for the V903 and VTA903 engines, ensuring precise valve movement and contributing to the engines’ performance and longevity.

CM2250 and V105 Engines

For the CM2250 and V105 engines, this push rod facilitates smooth valve operation, maintaining optimal valve timing and pressure, and enhancing engine performance.

Role in Engine Systems

Interaction with the Camshaft

The 3041013 transmits motion from the camshaft to the rocker arms, playing a vital role in the engine’s valve train system.

Lever and Rocker Arm Mechanism

This part interfaces with the rocker arm, which amplifies the motion, ensuring precise valve operation for efficient combustion.

Integration with Performance Parts

In high-performance engines, the 3041013 is crucial for handling increased stress and higher operational speeds, often requiring strengthened push rods.

Conclusion

The Cummins 3041013 Push Rod is a vital component in heavy-duty truck engines, ensuring precise valve timing and contributing to engine performance and reliability. Its robust construction, precise design, and compatibility with various engine models make it an essential part for maintaining and enhancing engine efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.