This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

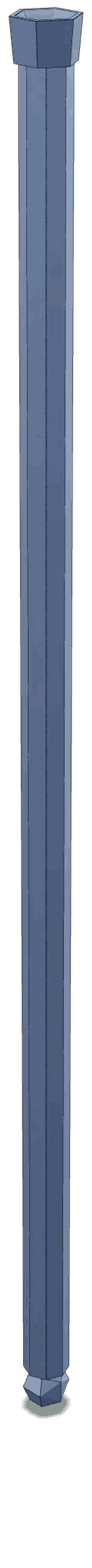

The Cummins 3054448 Push Rod is a component designed for use in heavy-duty truck engines. It facilitates the operation of the valvetrain system by transmitting motion from the camshaft to the valves, ensuring precise and efficient valve operation.

Basic Concepts of Push Rods

Push rods are mechanical linkages used in overhead valve (OHV) engines. They connect the camshaft, which is typically located in the engine block, to the rocker arms or other valve actuation mechanisms situated in the cylinder head. Push rods play a role in transferring the camshaft’s rotational motion into linear motion, which opens and closes the engine’s valves at the appropriate times 1.

Purpose of the Cummins 3054448 Push Rod

This Cummins part is integral to the engine’s valvetrain system. It interacts with the camshaft and rocker arms to ensure that the valves open and close in sync with the engine’s operation. This push rod is designed to withstand the high stresses and temperatures present in heavy-duty truck engines, contributing to reliable valve operation 2.

Key Features

The 3054448 is constructed from high-quality materials, ensuring durability and performance. Its design includes precise tolerances to facilitate smooth operation and reduce wear. Additionally, the push rod may feature specific coatings or treatments to enhance its resistance to corrosion and wear, further contributing to its longevity in demanding applications 3.

Benefits

Utilizing this part in an engine can lead to improved efficiency and reliability. Its robust construction and precise engineering help maintain optimal valve timing and operation, which can enhance engine performance and fuel efficiency. Moreover, the push rod’s durability contributes to the engine’s overall longevity, reducing the need for frequent replacements.

Installation and Maintenance

Proper installation of the Cummins 3054448 Push Rod is crucial for ensuring optimal engine performance. It should be installed according to the manufacturer’s guidelines, using the recommended tools and procedures to avoid damage. Regular maintenance, including inspection for signs of wear or damage, is important for ensuring the push rod continues to function correctly. Lubrication and cleanliness are also key factors in maintaining the push rod’s performance over time.

Troubleshooting Common Issues

Common issues with push rods can include wear, bending, or breakage, often due to excessive stress or inadequate lubrication. Diagnostic methods for identifying these problems may involve visual inspection, measurement of push rod length, and assessment of valve train noise or performance issues. Addressing these issues may require replacement of the push rod or other affected components, along with an investigation into the underlying causes to prevent recurrence.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the industry for quality and innovation, Cummins is committed to providing reliable and efficient components for various applications, including heavy-duty trucks. The company’s focus on engineering excellence and customer satisfaction underscores its position as a leader in the automotive and industrial sectors.

Conclusion

The Cummins 3054448 Push Rod plays a vital role in the operation of heavy-duty truck engines by ensuring precise and efficient valve operation. Its robust construction, precise engineering, and resistance to wear and corrosion contribute to improved engine performance, fuel efficiency, and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.