This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3424478 Push Rod Enclosure is a component designed to enhance the operation of heavy-duty trucks. Its purpose is to protect and guide the push rods within the engine, ensuring they function correctly and efficiently. This Cummins part plays a role in maintaining the engine’s performance and reliability, contributing to the overall efficiency of the truck 1.

Basic Concepts of Push Rod Enclosures

A push rod enclosure is a protective housing that encases the push rods in an engine. Push rods are mechanical links that transfer motion from the camshaft to the valves, allowing them to open and close at the correct times. The enclosure serves to shield the push rods from external contaminants and to maintain their alignment, which is vital for the engine’s operation. By keeping the push rods in proper position and protecting them, the enclosure helps maintain engine efficiency and performance 2.

Purpose of the 3424478 Push Rod Enclosure

The 3424478 Push Rod Enclosure is specifically designed to fit within Cummins engines, providing a secure environment for the push rods. It ensures that the push rods remain aligned and protected, which is crucial for the smooth operation of the engine. This enclosure contributes to the engine’s overall functionality by maintaining the integrity of the valve train system, thereby enhancing the engine’s performance and reliability 3.

Key Features

The 3424478 is constructed from durable materials that offer resistance to wear and corrosion. Its design includes precise dimensions to ensure a perfect fit within the engine compartment. Additionally, the enclosure may feature unique characteristics such as enhanced sealing properties to prevent the ingress of contaminants, and a design that allows for easy installation and maintenance 4.

Benefits

Using the 3424478 offers several benefits. It enhances engine performance by ensuring that the push rods operate within a protected environment, reducing the risk of misalignment or damage. The enclosure’s durable construction contributes to its longevity, providing a reliable component that can withstand the demanding conditions of heavy-duty truck operation. Furthermore, its design may offer improved protection against contaminants, which can lead to reduced maintenance requirements and extended engine life 1.

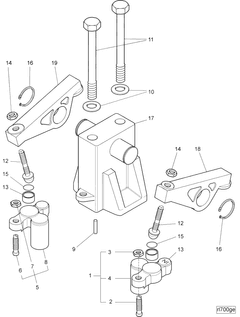

Installation Process

Installing the 3424478 involves several steps to ensure it is correctly positioned and secured within the engine. The process begins with preparing the engine compartment, ensuring it is clean and free from debris. The enclosure is then carefully aligned with the push rods and secured in place. It is important to follow the manufacturer’s instructions closely to ensure a successful installation. Tips for a successful installation include verifying the alignment of the enclosure with the push rods and ensuring all fasteners are tightened to the specified torque 2.

Troubleshooting and Maintenance

Common issues with the 3424478 may include misalignment or damage due to wear. Troubleshooting steps involve inspecting the enclosure for signs of wear or damage, and ensuring it is correctly aligned with the push rods. Maintenance tips include regular inspection of the enclosure for signs of wear, and cleaning it to remove any contaminants that may have accumulated. Proper maintenance can help ensure the longevity and optimal performance of the component 3.

Compatibility and Applications

The 3424478 is designed for use with specific Cummins engines, ensuring compatibility with a range of heavy-duty truck models. Its applications extend to various commercial truck settings, where it plays a role in enhancing engine performance and reliability. The enclosure’s compatibility with specific engine models ensures that it can be seamlessly integrated into the engine system, contributing to the efficient operation of the truck 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance engine components. The company’s commitment to quality and innovation is evident in its range of products, including the 3424478, which is designed to meet the demanding requirements of heavy-duty truck engines.

Cummins Push Rod Enclosure Part 3424478 Compatibility

The Cummins Push Rod Enclosure part number 3424478 is designed to fit seamlessly with a variety of Cummins engines. This part is crucial for maintaining the integrity and functionality of the engine’s push rod system. Below is a detailed overview of the engines with which this part is compatible:

Compatible Engines

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

Grouping of Compatible Engines

The Cummins Push Rod Enclosure part 3424478 is engineered to fit the following groups of engines:

-

QSV Series:

- QSV81G

- QSV91G

- QSW/QSV82

-

QSW Series:

- QSW27

- QSW36

- QSW73

-

QSV91-G4 CM558/CM700 V102

This part ensures that the push rod system operates smoothly, reducing wear and tear and enhancing the overall performance of the engine. Its compatibility with these engines underscores its versatility and importance in maintaining engine health.

Role of Part 3424478 Push Rod Enclosure in Engine Systems

The Part 3424478 Push Rod Enclosure is an integral component in the orchestration of various engine systems, ensuring the seamless transfer of motion from the camshaft to the valve train. This enclosure encapsulates the push rod, safeguarding it from external contaminants and enhancing the durability and efficiency of the engine’s valve operation.

Interaction with Cylinder Assembly Head

Within the cylinder assembly head, the Push Rod Enclosure works in tandem with the valve train components. It ensures that the motion transmitted from the camshaft via the push rod is accurately conveyed to the rocker and lever assemblies, facilitating the precise opening and closing of the valves. This interaction is fundamental for maintaining the engine’s combustion efficiency and overall performance.

Coordination with Lever and Rocker Assemblies

The enclosure’s role extends to its coordination with the lever and rocker assemblies. By housing the push rod, it allows for a stable and protected pathway for the rod to interact with the rocker lever assembly. This interaction is essential for the amplification of the camshaft’s motion, enabling the rocker to effectively actuate the valves with the required force and timing.

Integration with Push Assembly Rod

Directly interfacing with the push assembly rod, the enclosure ensures that the rod remains aligned and protected throughout its operational range. This alignment is vital for the consistent transmission of motion from the camshaft to the rocker lever assembly, contributing to the engine’s smooth operation and reliability.

Contribution to Rocker Assembly Lever and Rocker Lever Assembly

In the context of the rocker assembly lever and the rocker lever assembly, the Push Rod Enclosure plays a supportive role. It ensures that the push rod’s movement is unimpeded and precise, allowing the rocker lever assembly to perform its function of opening and closing the valves in synchronization with the engine’s combustion cycles. This precise motion is key to the engine’s performance, fuel efficiency, and emissions control.

Conclusion

In summary, the Part 3424478 Push Rod Enclosure is a pivotal component in the engine’s valve train system, facilitating the efficient and reliable operation of the cylinder assembly head, lever, rocker, and various assemblies involved in valve actuation. Its protective role ensures the longevity and performance of the engine, making it an essential part of the engine’s design.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ ↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ ↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ ↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.