This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3635142 Pressure Regulator Spring is a component designed to maintain consistent fuel pressure within the fuel system of commercial trucks. Its role is significant in ensuring the engine operates efficiently and reliably under various conditions. This spring is integral to the fuel delivery system, contributing to the overall performance and longevity of the engine 1.

Function and Operation

The Pressure Regulator Spring operates within the fuel system by regulating the pressure of the fuel delivered to the engine. It works in conjunction with other components to maintain a steady fuel pressure, which is crucial for optimal engine performance. The spring’s design allows it to counteract the pressure exerted by the fuel, ensuring that the pressure remains within the desired range regardless of changes in engine load or speed 2.

Key Features

The Cummins 3635142 Pressure Regulator Spring is engineered with specific design and construction features that enhance its performance and durability. These features include a precision-machined body, high-quality spring material, and a robust construction that can withstand the demanding conditions of commercial truck operations. The design ensures that the spring can maintain consistent pressure regulation over extended periods, contributing to the reliability of the fuel system 3.

Benefits

The advantages provided by the Pressure Regulator Spring include improved fuel efficiency, enhanced engine performance, and increased reliability. By maintaining consistent fuel pressure, the spring helps ensure that the engine receives the optimal amount of fuel, leading to more efficient combustion and better overall performance. Additionally, the consistent pressure regulation contributes to the longevity of the fuel system components, reducing the likelihood of failures and the need for frequent maintenance 4.

Installation and Maintenance

Proper installation of the Pressure Regulator Spring is crucial for ensuring optimal performance and longevity. It should be installed according to the manufacturer’s guidelines, which typically involve fitting it into the fuel system and securing it in place. Regular maintenance practices, such as inspecting the spring for signs of wear or damage and ensuring that it remains properly seated, are recommended to ensure continued reliable operation.

Troubleshooting Common Issues

Common problems associated with the Pressure Regulator Spring may include inconsistent fuel pressure, which can lead to engine performance issues. Troubleshooting steps may involve checking the spring for damage, ensuring it is properly installed, and verifying that there are no obstructions or leaks in the fuel system that could affect pressure regulation. Addressing these issues promptly can help maintain the efficiency and reliability of the engine.

Safety Considerations

When working with the Pressure Regulator Spring, it is important to follow safety precautions to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring that the fuel system is depressurized before beginning any work, and following all manufacturer guidelines for installation and maintenance. Adhering to these safety practices helps protect both the technician and the equipment.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and excellence, offering a wide range of engines and related components designed to meet the demanding needs of commercial transportation. The company’s commitment to quality and performance is evident in its product offerings, which are trusted by fleets and operators worldwide.

Compatibility with Cummins Engines

The Pressure Regulator Spring, identified by the part number 3635142, is a critical component in the fuel system of various Cummins engines. This part is essential for maintaining the correct fuel pressure within the system, ensuring optimal engine performance and efficiency. Below is a detailed description of its compatibility with the listed Cummins engines.

QSK45 CM500 and QSK60 CM500

The Pressure Regulator Spring is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and reliability in heavy-duty applications. The spring’s role in these engines is to regulate the fuel pressure, ensuring that the fuel injectors receive the correct amount of pressure to deliver the precise fuel quantity needed for combustion.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

For the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines, the Pressure Regulator Spring is equally vital. These engines are designed for high-performance applications, often found in marine and industrial settings. The spring’s function in these engines is to maintain consistent fuel pressure, which is crucial for the engines’ high-output capabilities and reliability under demanding conditions.

QSK60G

The QSK60G engine also benefits from the Pressure Regulator Spring. This engine is part of Cummins’ lineup of high-performance, heavy-duty engines. The spring ensures that the fuel pressure is regulated to the appropriate levels, supporting the engine’s performance and longevity.

QSK78 CM500

Lastly, the QSK78 CM500 engine is compatible with the Pressure Regulator Spring. This engine is designed for heavy-duty applications, and the spring’s role in regulating fuel pressure is essential for maintaining the engine’s efficiency and performance.

Role in Engine Systems

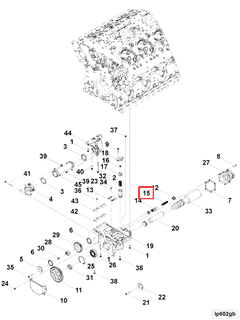

The Pressure Regulator Spring (Part 3635142) is an integral component in maintaining the optimal performance of various engine systems. Its primary function is to regulate the pressure within these systems, ensuring that they operate efficiently and reliably.

Lubricating Oil Pump

In the lubricating oil pump system, the Pressure Regulator Spring works in conjunction with the pump to maintain consistent oil pressure. This is essential for the proper lubrication of engine components, reducing friction and wear. The spring helps in modulating the flow of oil, ensuring that the pressure remains within the desired range, which is vital for the longevity and performance of the engine.

Pump Systems

Across various pump systems within the engine, the Pressure Regulator Spring plays a significant role in pressure management. Whether it is a fuel pump or a hydraulic pump, the spring ensures that the pressure does not exceed safe limits, preventing potential damage to the pump and other connected components. This regulation is key to maintaining the efficiency and reliability of the pump system.

Lubricating Oil System

Within the lubricating oil system, the Pressure Regulator Spring is responsible for maintaining the correct pressure of the lubricating oil. This is important for ensuring that all moving parts within the engine receive adequate lubrication. Proper lubrication is essential for minimizing wear and tear, enhancing the engine’s performance, and extending its operational life.

Conclusion

In summary, the Cummins 3635142 Pressure Regulator Spring is a vital component in ensuring that engine systems operate within their optimal pressure ranges. Its role in regulating pressure across various systems, including the lubricating oil pump and lubricating oil system, is essential for the efficient and reliable performance of the engine.

-

Fijalkowski, B.T. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.