This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Pressure Regulator Plunger 3918532 is a component manufactured by Cummins, a prominent name in the heavy-duty truck industry. This part is integral to the fuel system of heavy-duty trucks, where it helps manage fuel pressure to ensure efficient engine operation. Cummins is renowned for its robust and reliable engine components, and the Pressure Regulator Plunger is no exception.

Function and Operation

The Pressure Regulator Plunger operates within the fuel system by regulating the pressure of the fuel delivered to the engine. It interacts with other components such as the fuel pump and injectors to maintain a consistent fuel pressure. This regulation is achieved through a spring-loaded mechanism that adjusts the plunger’s position in response to changes in fuel pressure, thereby ensuring that the engine receives a steady supply of fuel under varying operating conditions 1.

Purpose of the Pressure Regulator Plunger

The primary role of the Pressure Regulator Plunger is to ensure optimal fuel delivery, which is vital for maintaining engine performance. By stabilizing fuel pressure, it helps prevent issues such as fuel starvation or over-pressurization, both of which can adversely affect engine efficiency and longevity. Consistent fuel pressure is crucial for the precise operation of fuel injectors, which in turn impacts combustion efficiency and overall engine performance 2.

Key Features

The Pressure Regulator Plunger 3918532 is designed with several features that enhance its effectiveness and durability. These include a precision-machined body that ensures accurate pressure regulation, high-quality materials that resist wear and corrosion, and a robust spring mechanism that provides reliable performance under a range of operating conditions. These features contribute to the part’s ability to maintain consistent fuel pressure and support long-term engine reliability.

Benefits

Incorporating the Pressure Regulator Plunger into a heavy-duty truck’s fuel system offers several advantages. These include improved fuel efficiency due to optimized fuel delivery, enhanced engine performance through consistent fuel pressure, and reduced wear on fuel system components, which can lead to longer component lifespan and lower maintenance costs. Additionally, stable fuel pressure contributes to smoother engine operation and can help in meeting emissions standards.

Installation and Compatibility

Proper installation of the Pressure Regulator Plunger is important to ensure it functions correctly within the fuel system. It is designed to be compatible with various Cummins engine models, though specific installation procedures may vary depending on the engine type. Following manufacturer guidelines during installation helps ensure the part operates as intended and integrates seamlessly with the existing fuel system components.

Maintenance and Troubleshooting

Regular maintenance of the Pressure Regulator Plunger is important to ensure its continued performance and longevity. This includes periodic inspection for signs of wear or damage, cleaning to remove any contaminants that may affect its operation, and replacement of the part if it shows signs of failure. Common issues may include inconsistent fuel pressure, which can be diagnosed through pressure testing and other diagnostic methods. Adhering to recommended maintenance schedules can help prevent unexpected failures and ensure optimal engine performance.

Common Failure Modes

Typical failure modes for the Pressure Regulator Plunger may include spring fatigue, plunger wear, or contamination within the fuel system. These issues can lead to inconsistent fuel pressure, affecting engine performance. Identifying the root cause of failure, whether it be due to normal wear, improper installation, or external factors such as fuel contamination, is important for effective troubleshooting and repair. Solutions may range from cleaning and adjustment to replacement of the part.

Impact on Engine Performance

The Pressure Regulator Plunger plays a role in engine performance by ensuring that fuel is delivered at the correct pressure. This contributes to efficient combustion, which is important for fuel economy, power output, and emissions. Stable fuel pressure helps the engine operate smoothly under various conditions, which can lead to improved overall performance and reliability.

Cummins Corporation

Cummins Corporation, the manufacturer of the Pressure Regulator Plunger 3918532, has a long-standing reputation in the heavy-duty truck industry. Founded in 1919, Cummins has grown to become a global leader in diesel engine manufacturing, with a diverse product range that includes engines, filtration systems, and aftermarket parts. The company is known for its commitment to quality, innovation, and customer satisfaction, making it a trusted name among fleet operators and maintenance professionals.

Compatibility with Cummins Engines

The Pressure Regulator Plunger 3918532 is compatible with a range of Cummins engines, which can be grouped based on their model series and specifications:

- 6B5.9 and 6C8.3

- C GAS PLUS CM556

- C8.3 G and G8.3

- ISC CM554, ISL CM554, QSC8.3 CM554, and QSL9 CM554

Each of these engines relies on the Pressure Regulator Plunger to maintain the correct fuel pressure, ensuring that the engine operates smoothly and efficiently. This part is essential for the proper functioning of the fuel system, and its compatibility across these models underscores its versatility and importance in Cummins engine technology.

Role in Engine Systems

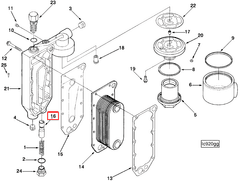

The Pressure Regulator Plunger is integral to maintaining optimal pressure within the engine’s lubrication system. It works in conjunction with several key components to ensure efficient engine operation.

Interaction with the Lubricating Pump Kit

When integrated with the Lubricating Pump Kit, the Pressure Regulator Plunger helps modulate the oil pressure delivered to various engine parts. This ensures that components such as the cylinder block and engine head receive consistent lubrication, reducing wear and enhancing performance.

Coordination with the Oil Filter and Full Flow Oil System

In systems equipped with an Oil Filter and Full Flow Oil configuration, the Pressure Regulator Plunger plays a role in stabilizing pressure fluctuations. This is particularly important in maintaining the efficiency of the oil filter, ensuring that contaminants are effectively removed from the engine oil before it circulates through the system.

Integration with the Oil Filter Cooler

For engines that include an Oil Filter Cooler, the Pressure Regulator Plunger assists in maintaining a steady oil temperature. By regulating pressure, it helps in efficient heat exchange, which is vital for the longevity and performance of the engine oil.

Application in Short Block and Long Block Assemblies

In both Short Block 6Cart and Long Block assemblies, the Pressure Regulator Plunger is essential for balancing oil pressure. This is crucial for the proper functioning of internal components, such as bearings and pistons, which rely on precise lubrication for optimal performance.

Use in Engine Kits and Ford Dealer Components

When included in Engine Kits or components sourced from a Ford Dealer, the Pressure Regulator Plunger ensures that the lubrication system operates within specified parameters. This is important for maintaining the warranty and performance standards set by the manufacturer.

Role in the Cooler and Filter System

The Pressure Regulator Plunger also interacts with the Cooler and Filter system to ensure that the engine oil is not only clean but also delivered at the correct pressure. This dual function is essential for the overall health of the engine, particularly in high-stress operating conditions.

Conclusion

The Pressure Regulator Plunger 3918532 is a critical component in both the fuel and lubrication systems of Cummins engines. Its role in maintaining consistent fuel and oil pressure is vital for ensuring efficient engine operation, reducing wear on engine components, and enhancing overall performance and reliability. Proper installation, regular maintenance, and understanding its compatibility with various Cummins engine models are key to maximizing the benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.